Resin compositions with high thermoplatic loading

a technology of thermoplastic resin and composition, applied in the direction of synthetic resin layered products, chemistry apparatus and processes, transportation and packaging, etc., can solve the problems of high viscosity and high tack, resin cannot be fabricated into films or handled during multi-component structure fabrication, and the amount of thermoplastic resins that can be added to the thermoplastic resin mixture is limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0034] A resin precursor was made having the following formulation:

[0035] 27.0 weight percent MY-0510 (N,N-Diglycidyl-4-glycidyloxyaniline)

[0036] 24.9 weight percent GY285 (bis-F epoxy)

[0037] 15.8 weight percent 3,3′-Diaminodiphenylsulfone

[0038] 1.3 weight percent Dicyandiamide

[0039] 13.5 weight percent micronized Polyethersulfone (PES)

[0040] 17.5 weight percent densified Polyethersulfone (PES)

[0041] Precursor resin formulations in accordance with this example may also be made wherein the amounts of MY-510, GY281 and 3,3-DDS are varied by up to ±15%. Also, the amounts of both types of PES may be varied by as much as ±40%. The amount of dicyandiamide may be varied by up to ±50%. The densified PES was made from PES 5003 P, which is available from Sumitomo Chemical Co. Ltd. (Osaka, Japan). The PES was densified in accordance with U.S. Pat. No. 4,945,154. Average particle size was 10-25 microns with no more than 13 weight percent smaller than 5 microns and no more than 4 weight p...

example 2

[0043] The same combination of thermosetting resins and curing agents as set forth in Example 1 were used to make resin precursors that contained 25, 37.5 and 50 weight percent PES. The PES was added in the same manner as Example 1 except that the differences in overall PES loading was accounted for by varying the amount of densified PES that was added. The amount of micronized PES that was initially dissolved was kept constant at 13.5 weight percent. Films of resin precursor were made in the same manner as Example 1. The films were subjected to the same heat treatment step with the same dissolution process being observed. The resulting uncured resin films underwent the same color change from opaque white to translucent amber-brown. The tack of the uncured resin films was also substantially less than the resin precursor films and the final viscosity of the uncured resin films was substantially higher.

example 3

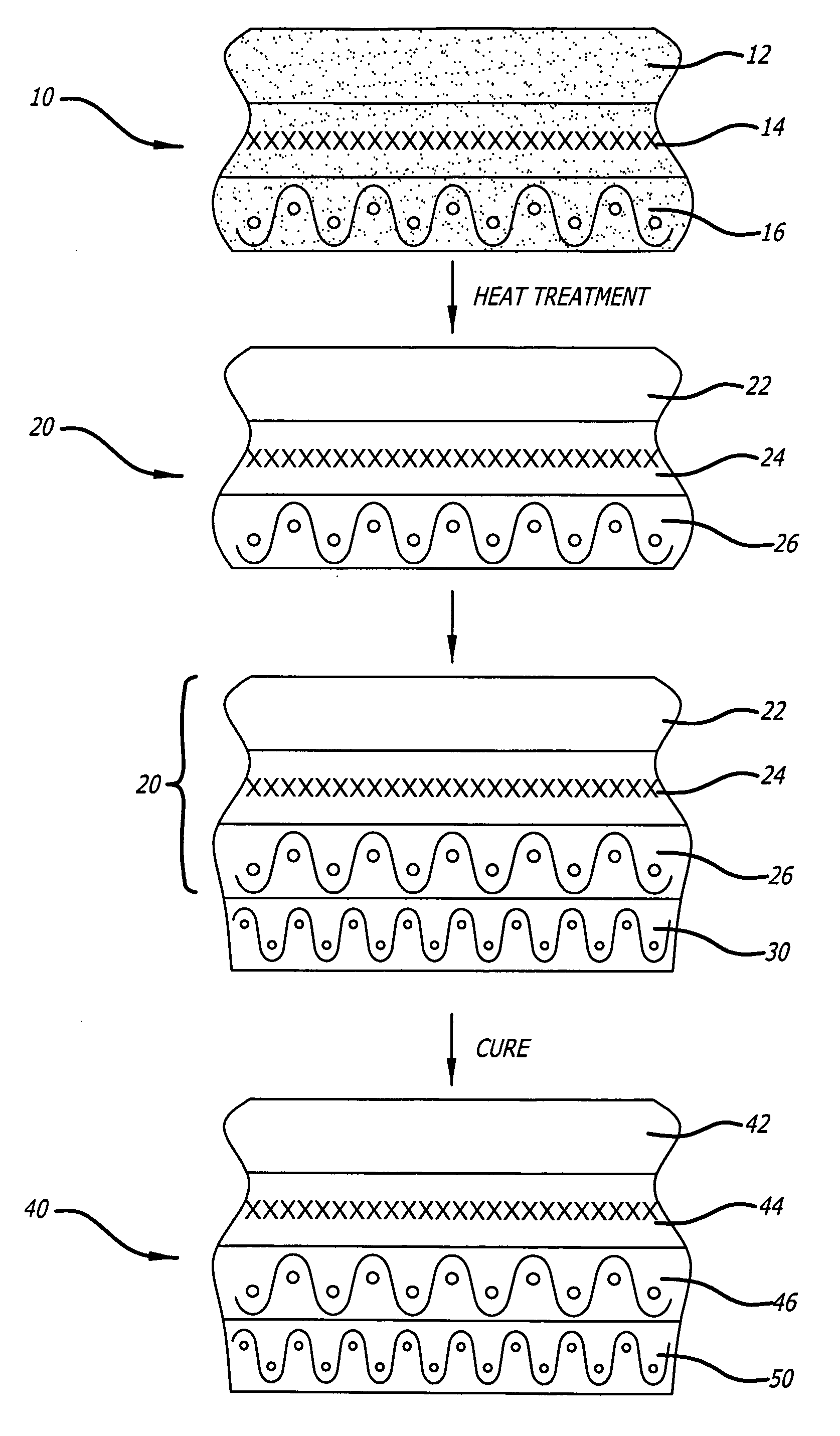

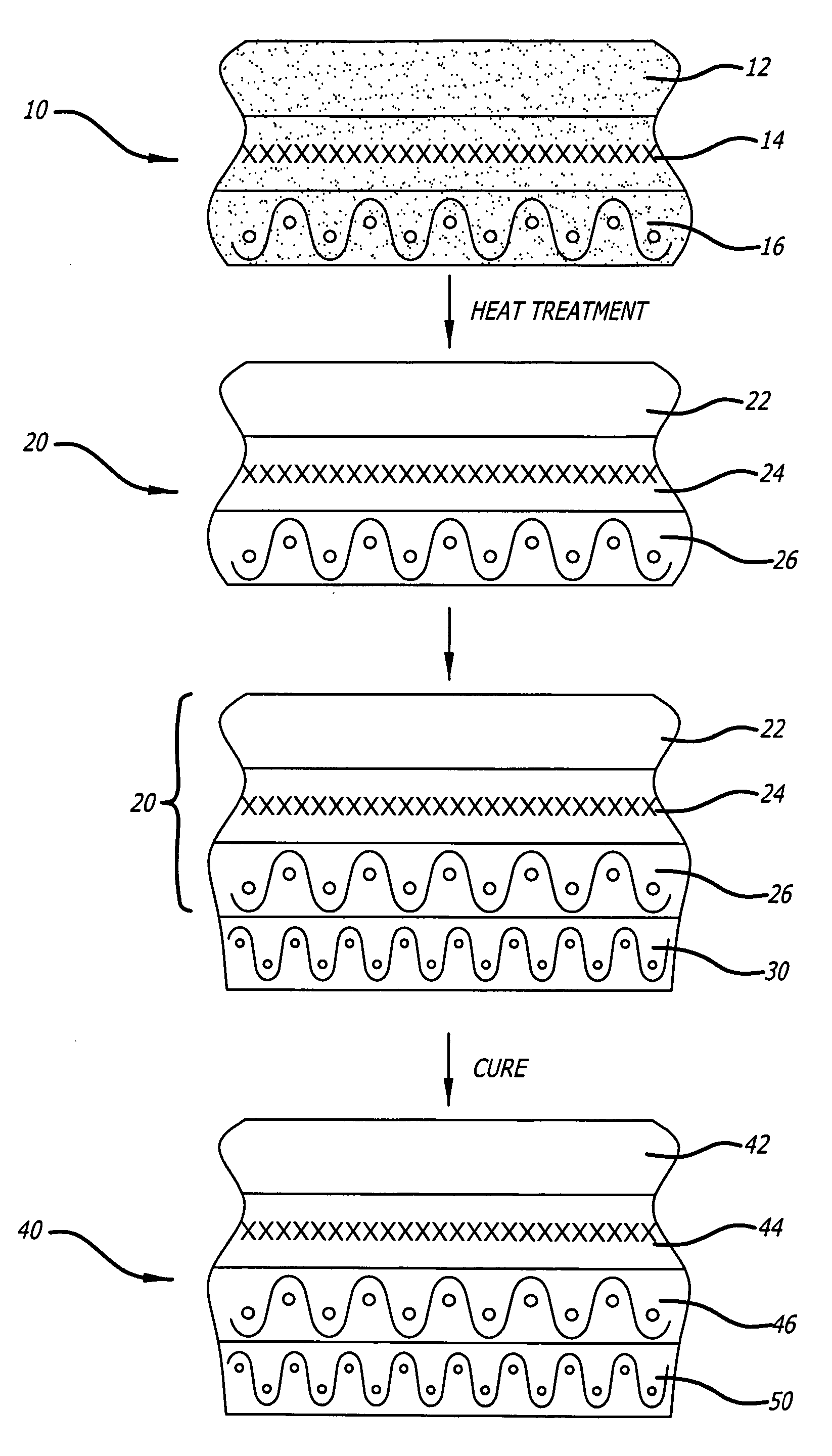

[0044] A three layer uncured electrically conductive composite material as shown in the drawing was made as follows:

[0045] A resin precursor resin film 12 was prepared according to Example 1. The film 12 was combined with an expanded aluminum foil 14 and a prepreg 16 that was composed of 6080-glass fabric (48 gsm) and resin precursor (32 gsm) that was prepared as described in Example 1. The resulting lay-up 10 was heat treated for 5 minutes at 110° C. in order to substantially dissolve the PES particles without curing the 1-up. The resulting uncured electrically conductive composite structure 20 had substantially reduced tack.

[0046] The uncured composite structure 20 was applied as a surfacing layer to a number of composite structures that were each composed of 8 plies of unidirectional prepreg. The unidirectional prepreg contained unidirectional carbon fibers in an uncured epoxy resin matrix. The orientation of the unidirectional plies was −45, 90, 45 and 0. Upon final curing at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com