Apparatus and method for dispensing frozen carbonated beverages

a technology for carbonated beverages and apparatuses, applied in lighting and heating apparatus, ice production, refrigeration machines, etc., can solve the problems of large floor space and bulky apparatuses, and achieve the effect of enhancing the carbonation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

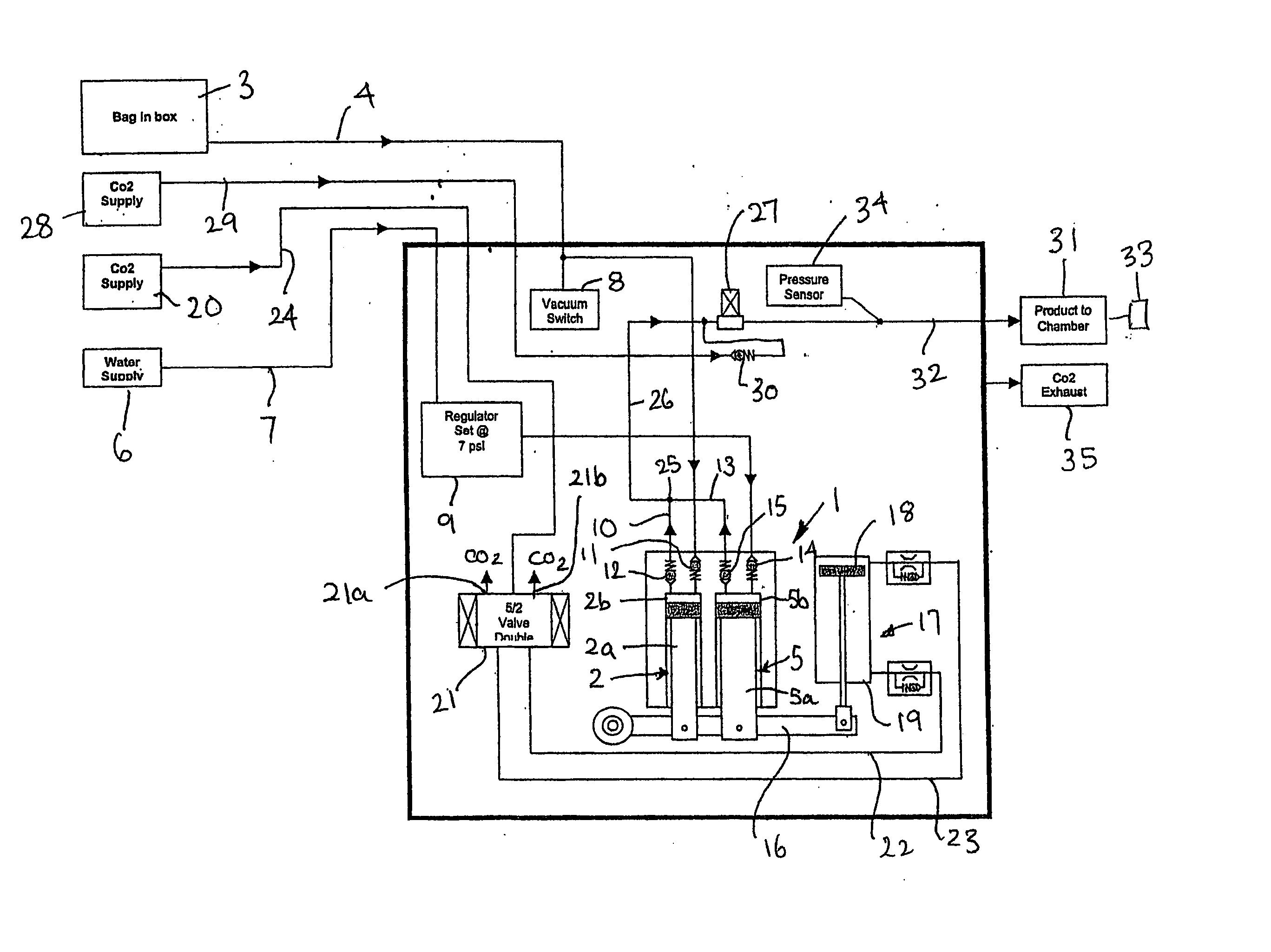

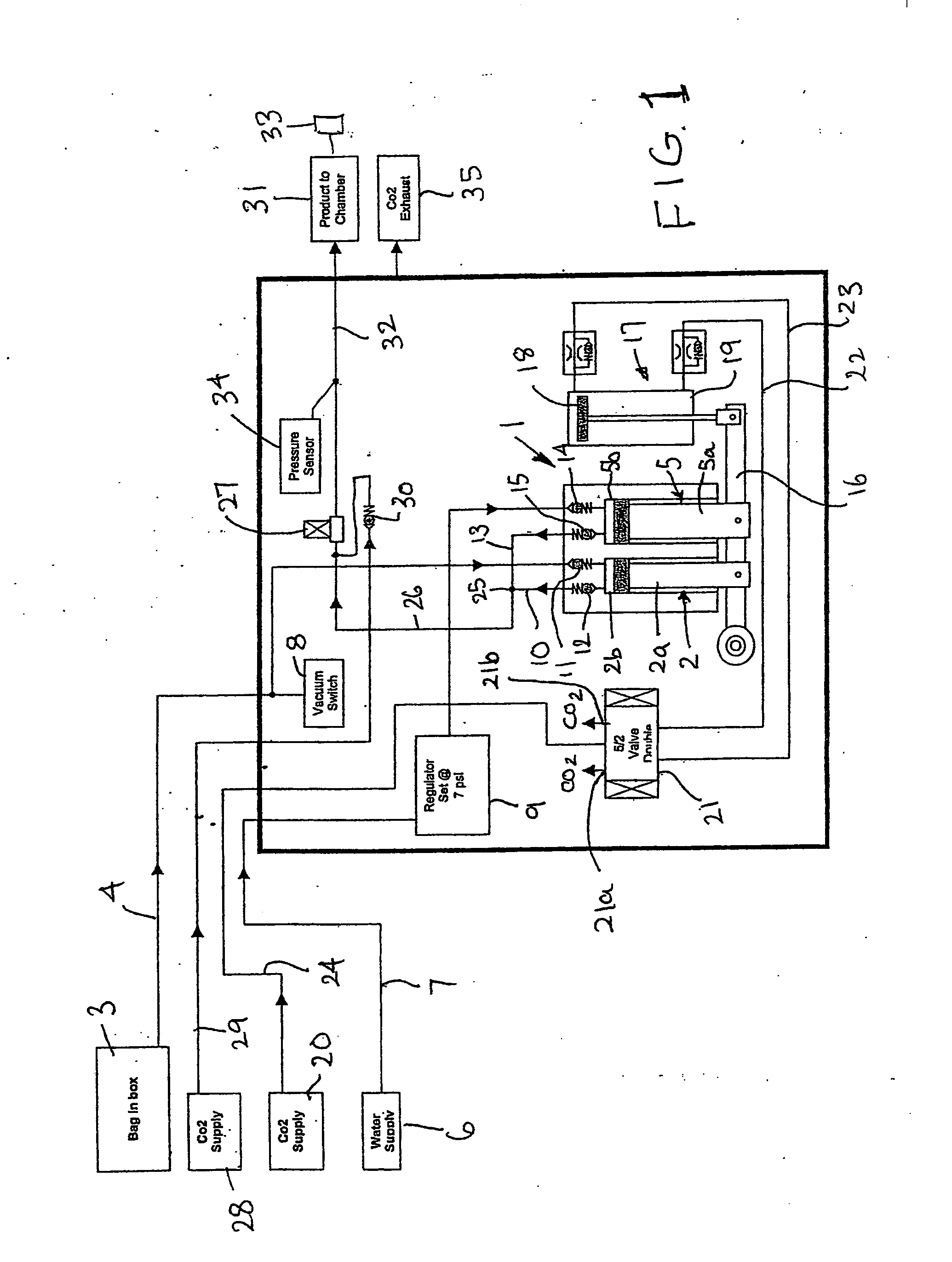

[0032] The invention will now be described in more detail, by way of example only, with reference to the accompanying FIG. 1 schematic drawing of one embodiment of an apparatus for dispensing frozen carbonated beverages according to the invention.

[0033] As shown the apparatus has a ratio pump 1 having a syrup pump unit 2 connected to a source 3 of syrup via a syrup line 4 and a water pump unit 5 connected to a source 6 of water via a water line 7. In this embodiment the source 3 of syrup is a so-called “bag in box” container and the source 6 of water is the mains supply. It will be understood however that any other suitable sources of syrup and water may be employed.

[0034] A vacuum switch 8 is provided in the syrup line 4 to detect when the syrup source 3 is empty and provide a signal to an electronic control unit (not shown), for example a printed circuit board, to shut-down the ratio pump 1 until the syrup source 3 is replaced. A visual and / or audible warning signal may be provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com