Pad conditioner for conditioning a cmp pad and method of making such a pad conditioner

a conditioner and pad technology, applied in the field of pad conditioners, can solve the problems of reducing the removal rate of polishing, reducing and reducing so as to enhance the stability of the cmp process, prolong the life of polishing pads, and improve the efficiency and uniformity of pad conditioners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A pad conditioner for conditioning a CMP pad and a method of making such a pad conditioner according to a preferred embodiment of the invention will be described below with reference to the drawings, wherein the like reference numerals denote the like components. Please note that the embodiments of the invention described below are for explanatory purposes and are not limited to the description thereof unless such limitation is specified in the embodiments.

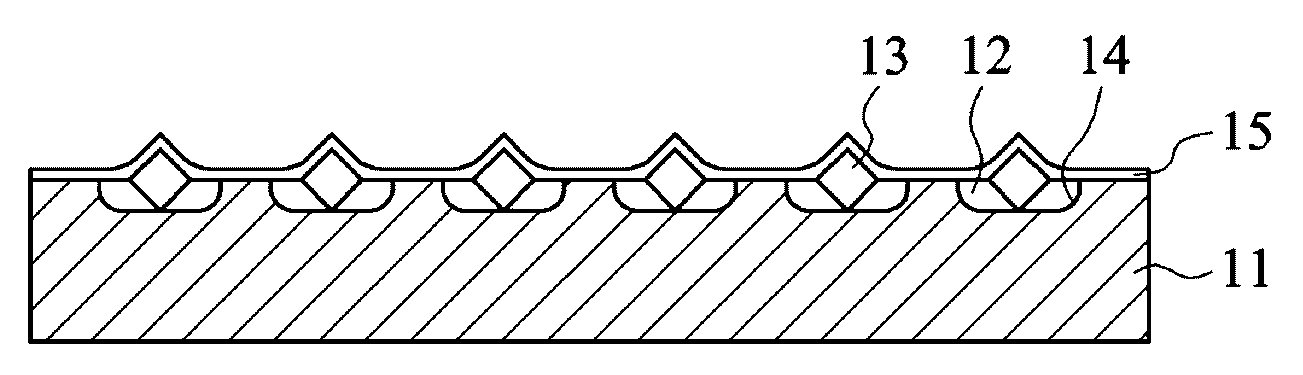

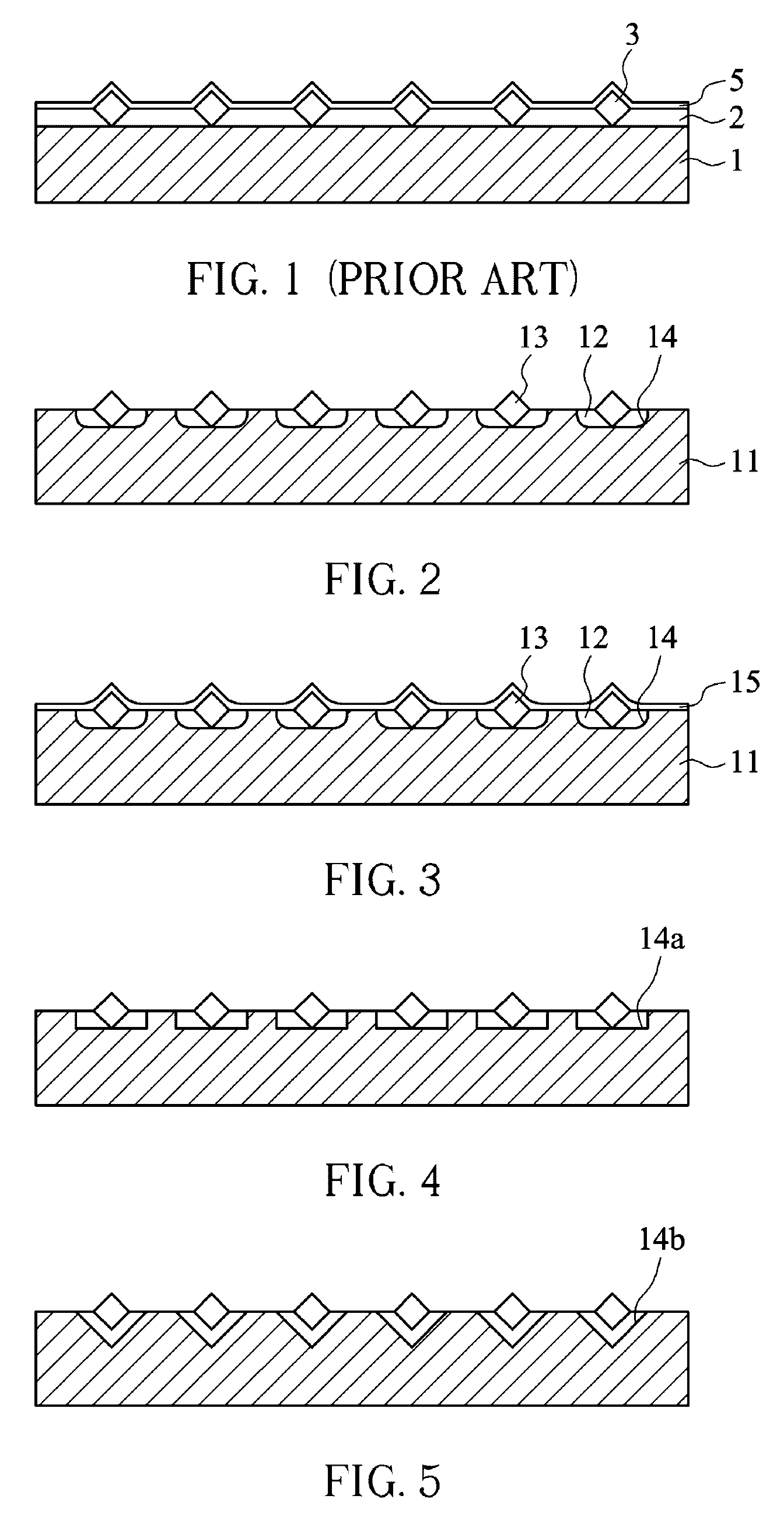

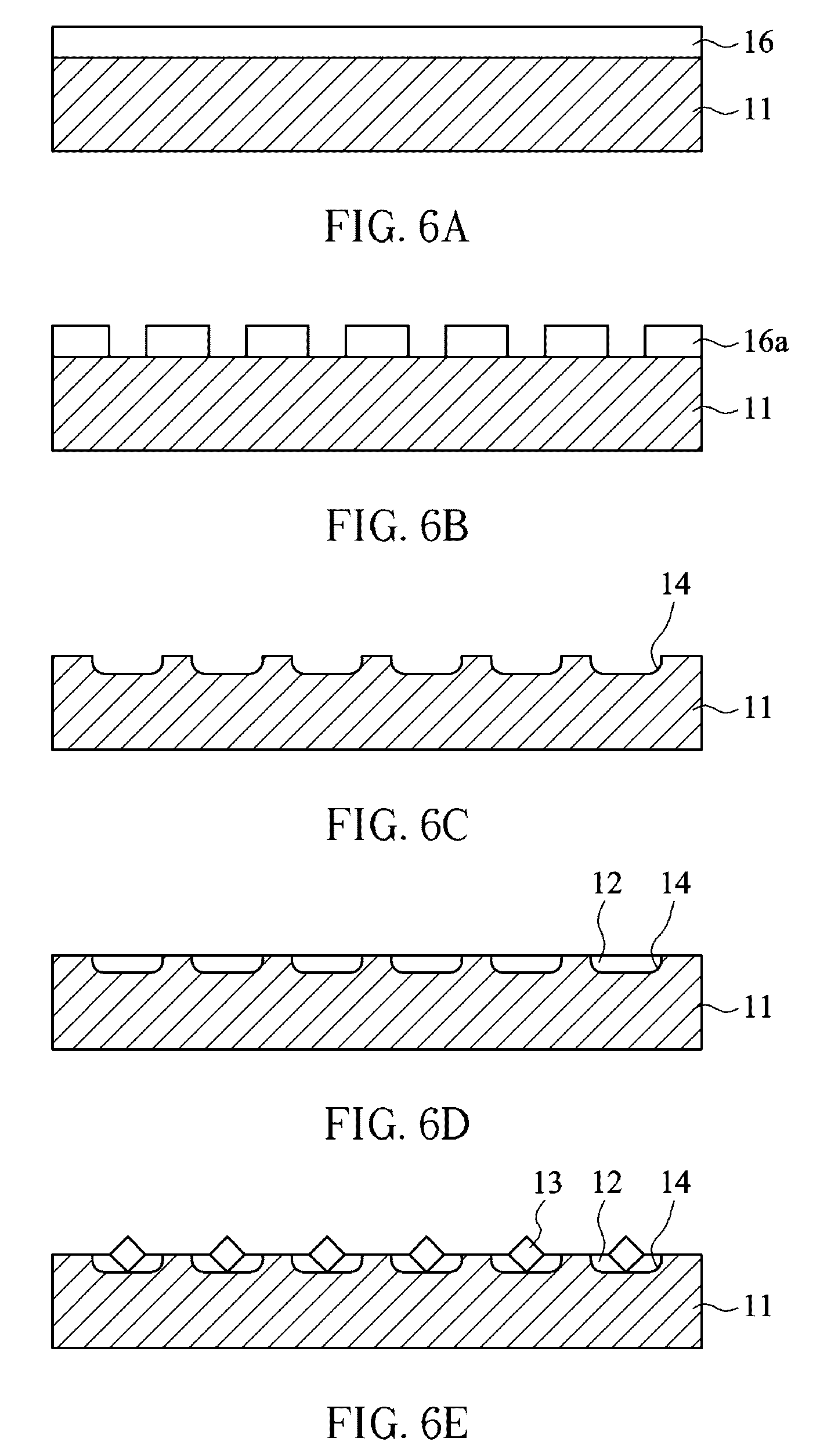

[0030] Referring to FIG. 2, a sectional view of a pad conditioner according to a first embodiment of the invention is disclosed, wherein a plurality of abrasive particles 13 are respectively fixed in a plurality of flat-bottom, bowl-shaped cavities 14 on a substrate 11 by a bonding agent 12. In this embodiment, the substrate 11 is made of stainless steel SUS 316, and the sizes of the abrasive particles are from about 100 μm to about 250 μm, preferably about 130 μm to about 200 μm. The depth of the cavities 14 is about 50 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sizes | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com