Mopping system and method of use

a technology of mopping head and mop head, which is applied in the field of mopping, can solve the problems of affecting the cleaning effect of mop head, and accumulating significant amount of water fouling material, etc., and achieves the effects of convenient application, quick and thorough cleaning and drying, and preventing contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

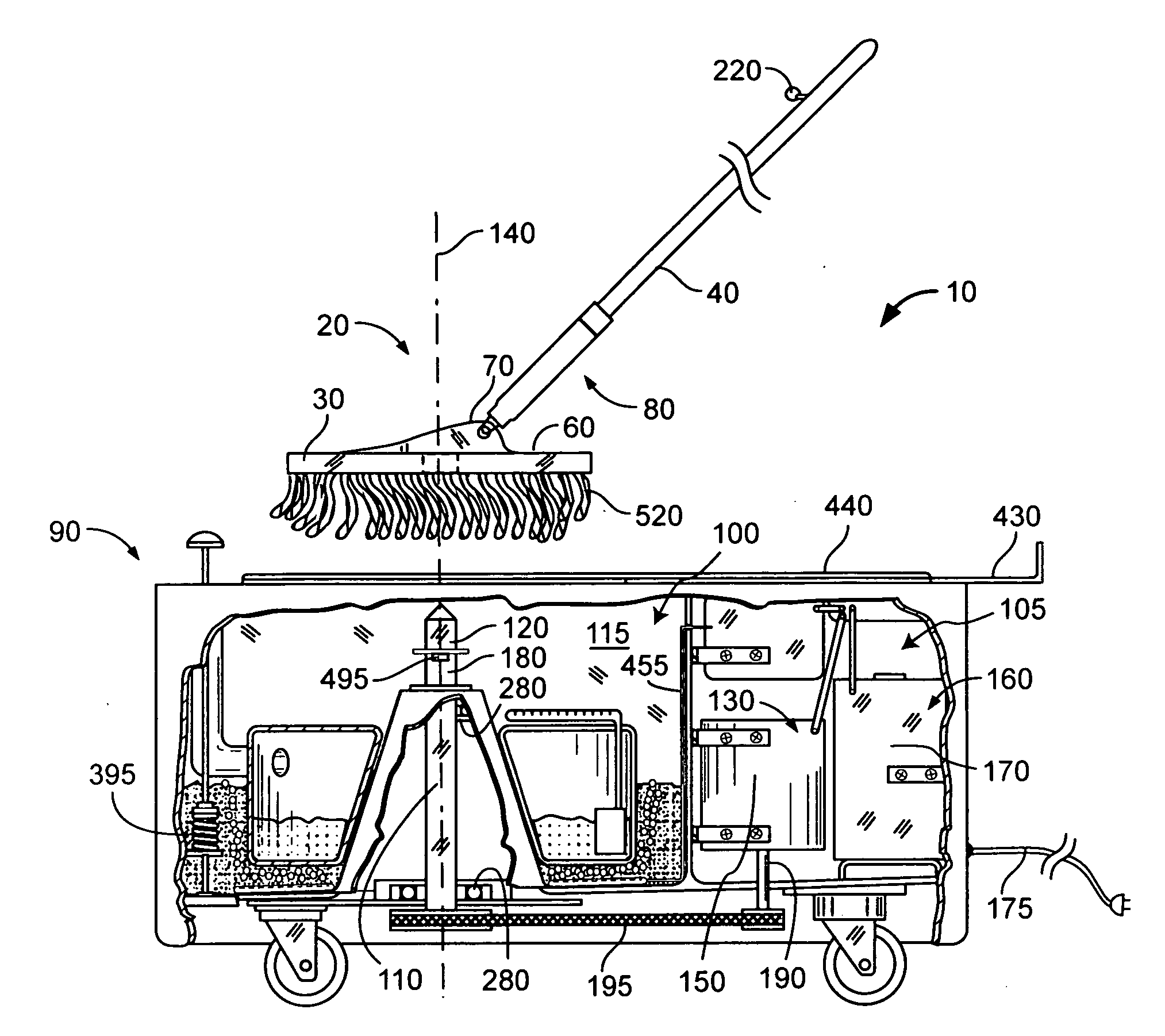

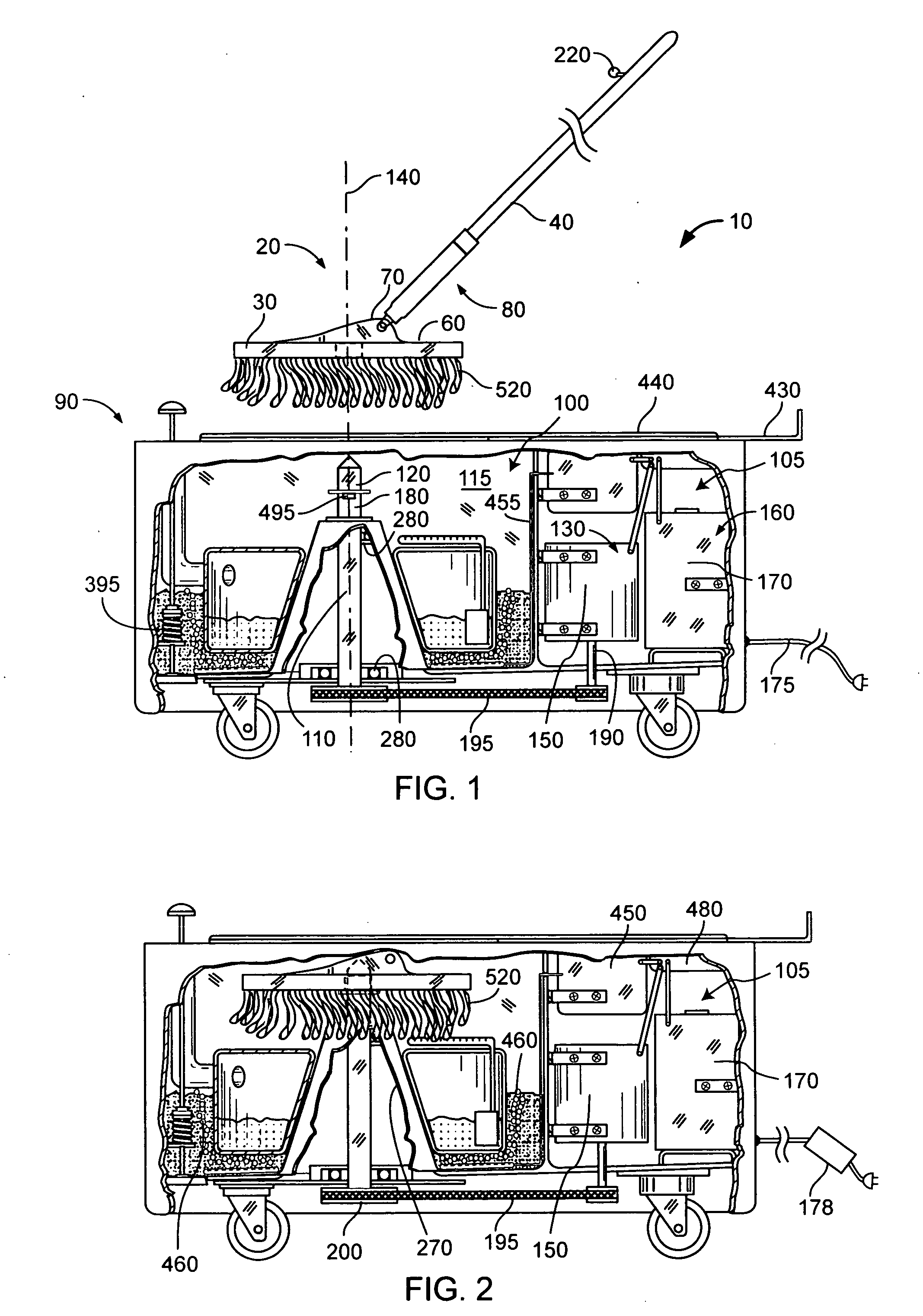

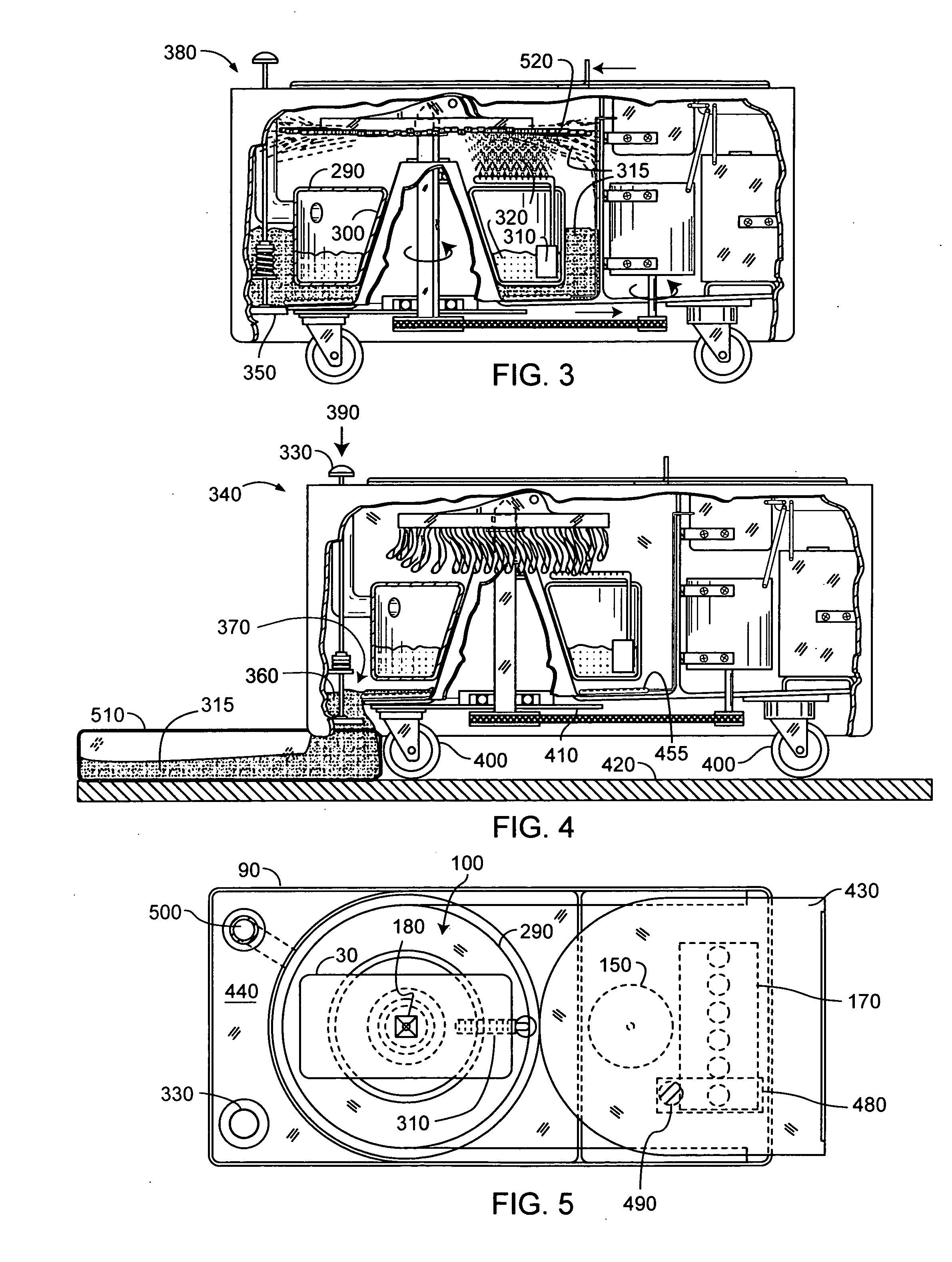

[0023]FIG. 1 illustrates a mopping system 10 of the present invention. In its simplest form, the mopping system 10 comprises a mop assembly 20 and a bucket assembly 90. The mop assembly includes a mop head 30 preferably pivotally attached to an elongated handle 40. The mop head 30 includes a floor-engageable lower surface 50 (FIG. 8) and an opposing upper surface 60. The mop head 30 includes a handle attachment means 70, preferably on the upper surface 60, for attaching the mop head 30 to a lower end 80 of the handle 40 (FIGS. 7-9). The handle attachment means 70 could also be provided on a peripheral edge of the mop head 30 (not shown).

[0024] The mop head 30 is preferably detachable from the elongated handle 40 so that the mop head 30 may be easily spun in the bucket assembly 90 without the need to also spin the handle 40. However, such an arrangement is not necessarily required in an embodiment of the invention that allows for spinning the entire mop assembly 20 by aligning the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com