Metal nanowire array and method for fabricating the same

a metal nanowire and array technology, applied in the field of nanomaterials, can solve the problem of relative little progress reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

0F PREFERRED EMBODIMENTS

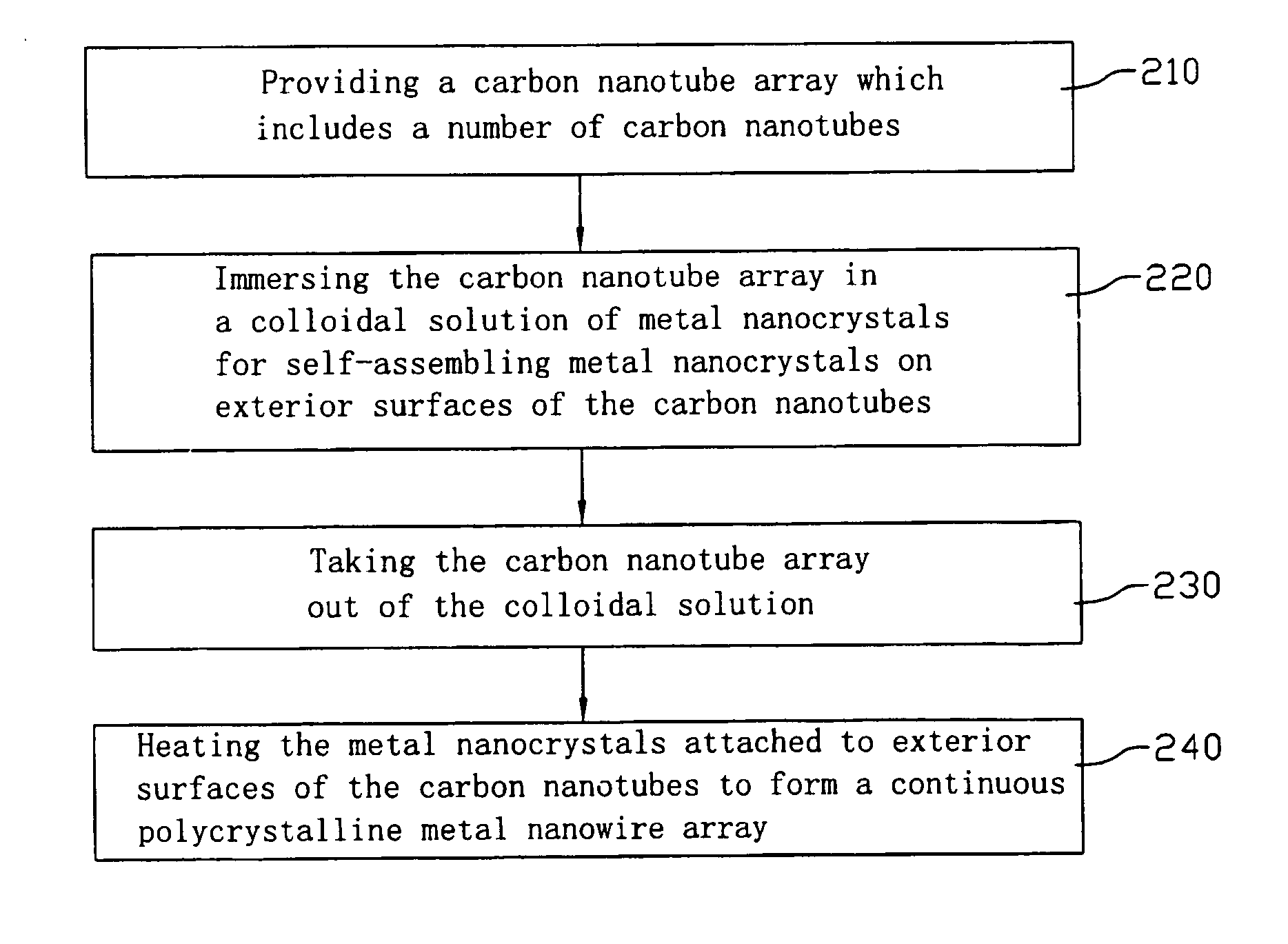

[0014] Referring now to FIG. 1, a metal nanowire array 100 in accordance with the preferred embodiment includes a substrate 110 and an array of metal nanowires 120 extending in a substantially common direction. Each of the metal nanowires 120 includes a core portion 122 and a cladding portion 124. The core potion 122 is enclosed in the cladding portion 124. It should be noted that the cladding portion 124 could be partially or entirely formed on / enclosing an exterior surface of the core portion 122 and which should be considered to be within the scope of the present invention. The core portion 122 may include a single carbon nanotube or a plurality of bundled carbon nanotubes. The carbon nanotubes may be formed on the substrate 110. The cladding portion 124 includes metal polycrystalline, the metal can be selected from the group consisting of gold, silver, copper, tin, nickel, and germanium. Because of the strength of the aligned structure of the metal nanowi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| time period | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com