Compound bows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

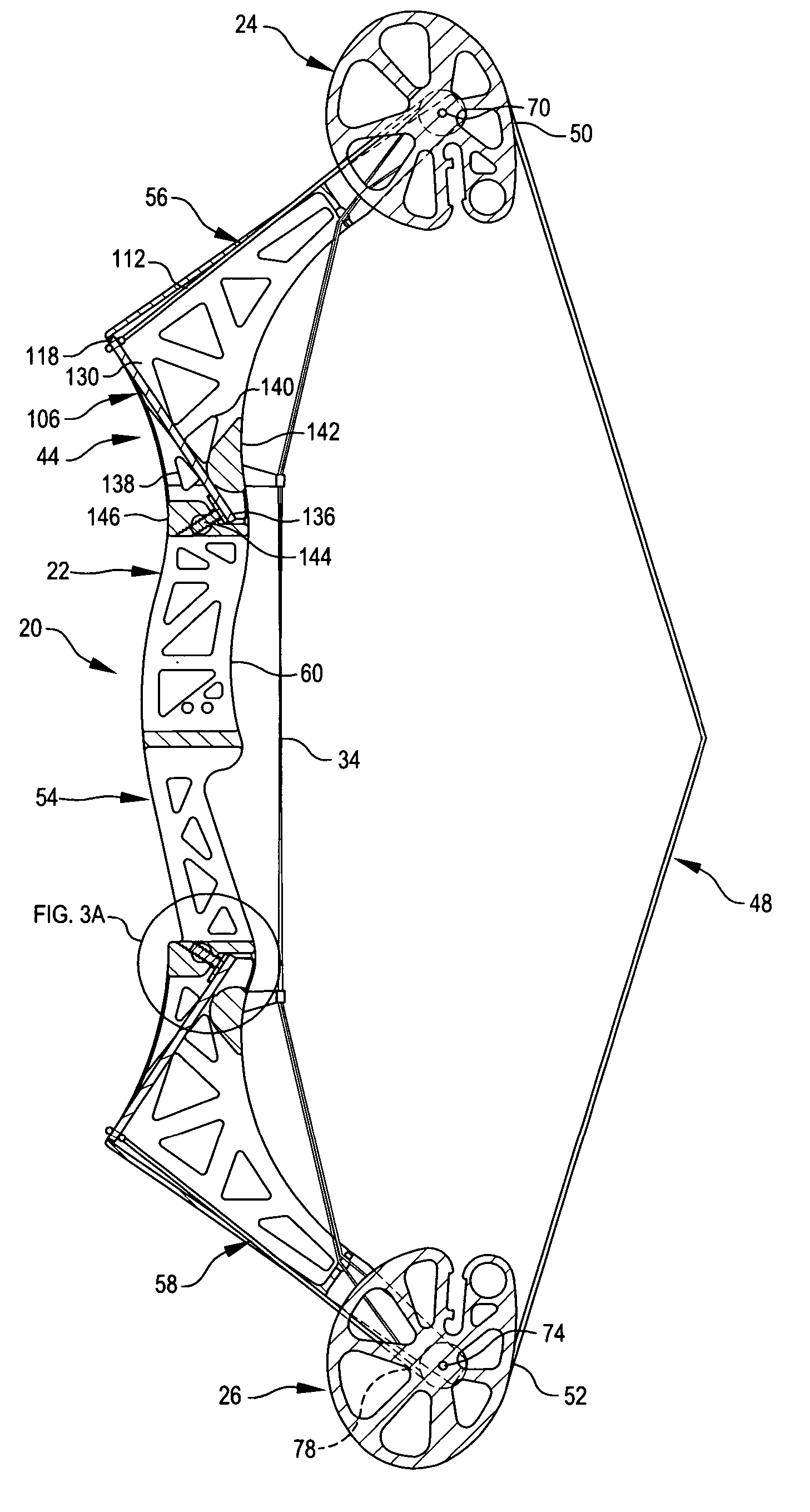

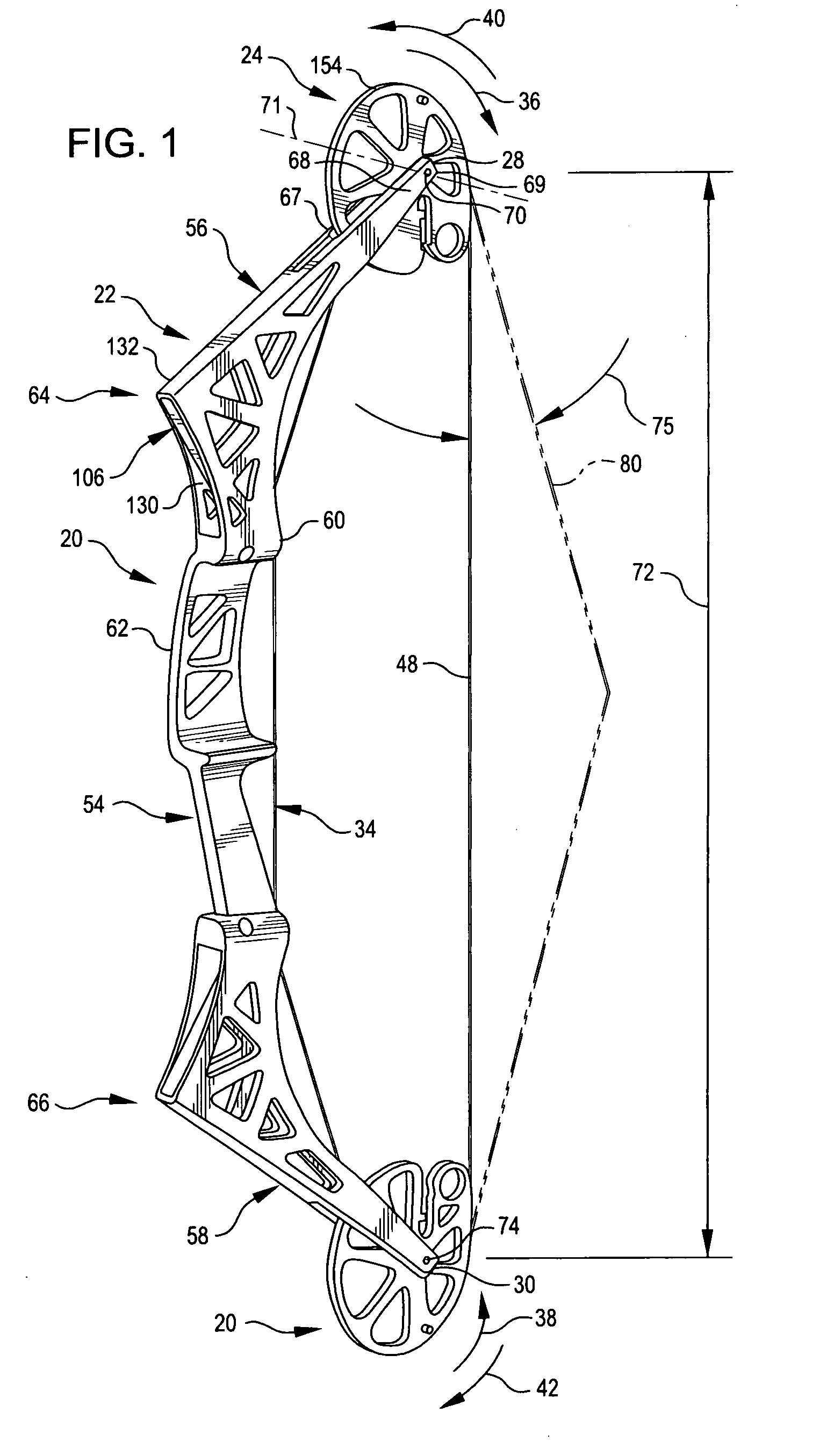

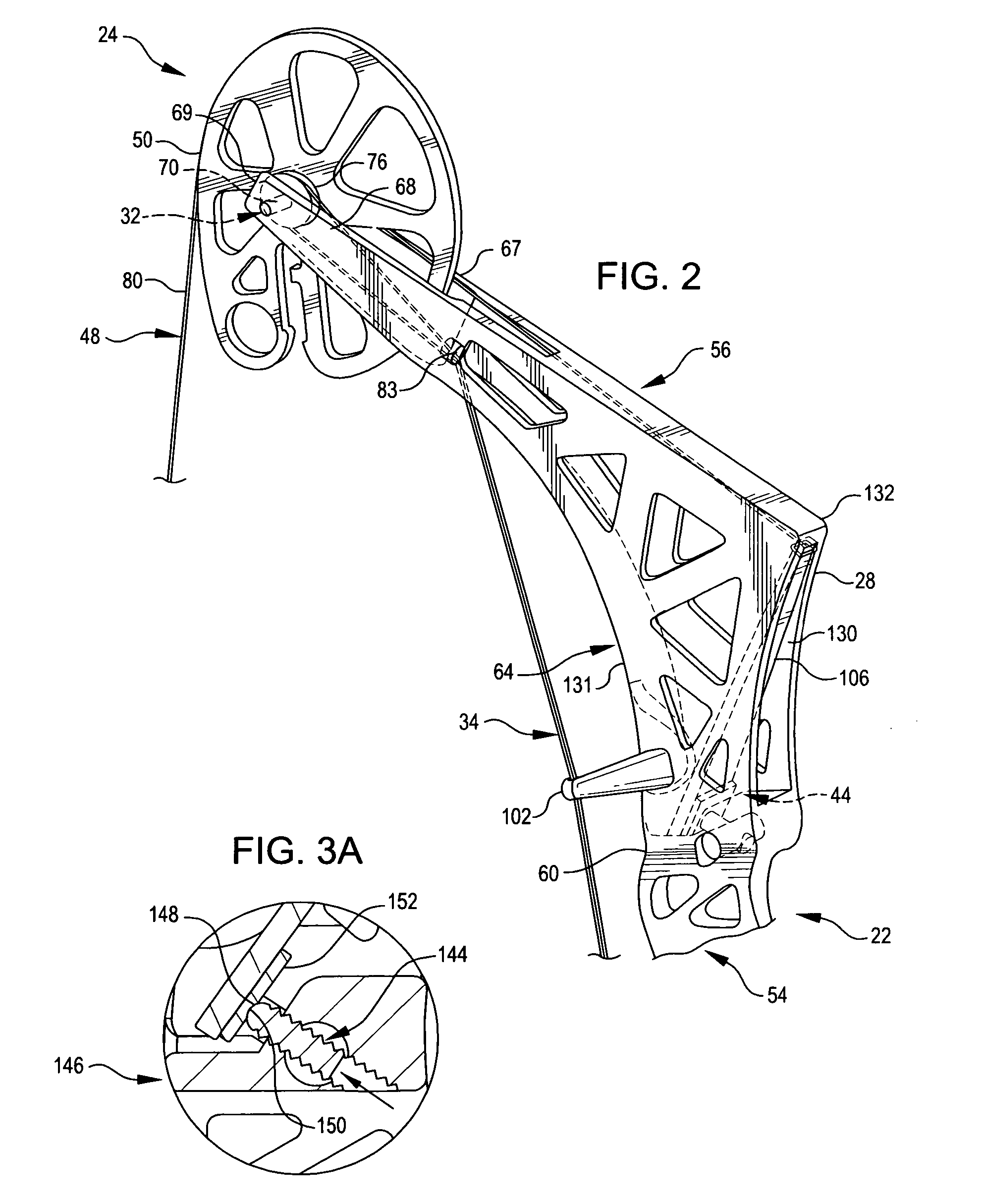

[0060] Referring now to the drawings, FIGS. 1 and 2 depicts a compound archery bow 20 constructed in accord with and embodying the principles of the present invention. The major components of bow 20 include an elongated, rigid riser 22; string cams 24 and 26 at the upper and lower ends 28 and 30 of riser 22; a timing system 32 (see especially FIGS. 6-8), including a timing cable 34 for synchronizing the counter rotation of string cams 24 and 26 suggested by arrows 36 / 38 and 40 / 42 in FIG. 1; and riser-mounted power units 44 and 46 (see especially FIGS. 3-6) which store arrow propelling energy in potential form as bow 20 is drawn. A bow string 48 extends between and is connected at its opposite ends 50 and 52 to the upper and lower string cams 24 and 26. With the components of bow 20 in their rest configurations and positions, bow string 48 lies along a straight line located to the rear of riser center section 54. When bow 20 is fully drawn, bow string 48 is configured as shown in pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com