Power efficient flow through capacitor system

a capacitor and fluid technology, applied in the direction of electric circuits, manufacturing tools, electric circuits, etc., can solve the problems of increasing the wattage rating and cost of power supplies needed to provide power, the need to operate with a greater number of stages, and the need to reach a lower voltage limit, so as to reduce the amount of dead volume, reduce the need, cost and complication of connecting, and eliminate the need of connecting. , the effect of increasing the number of stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

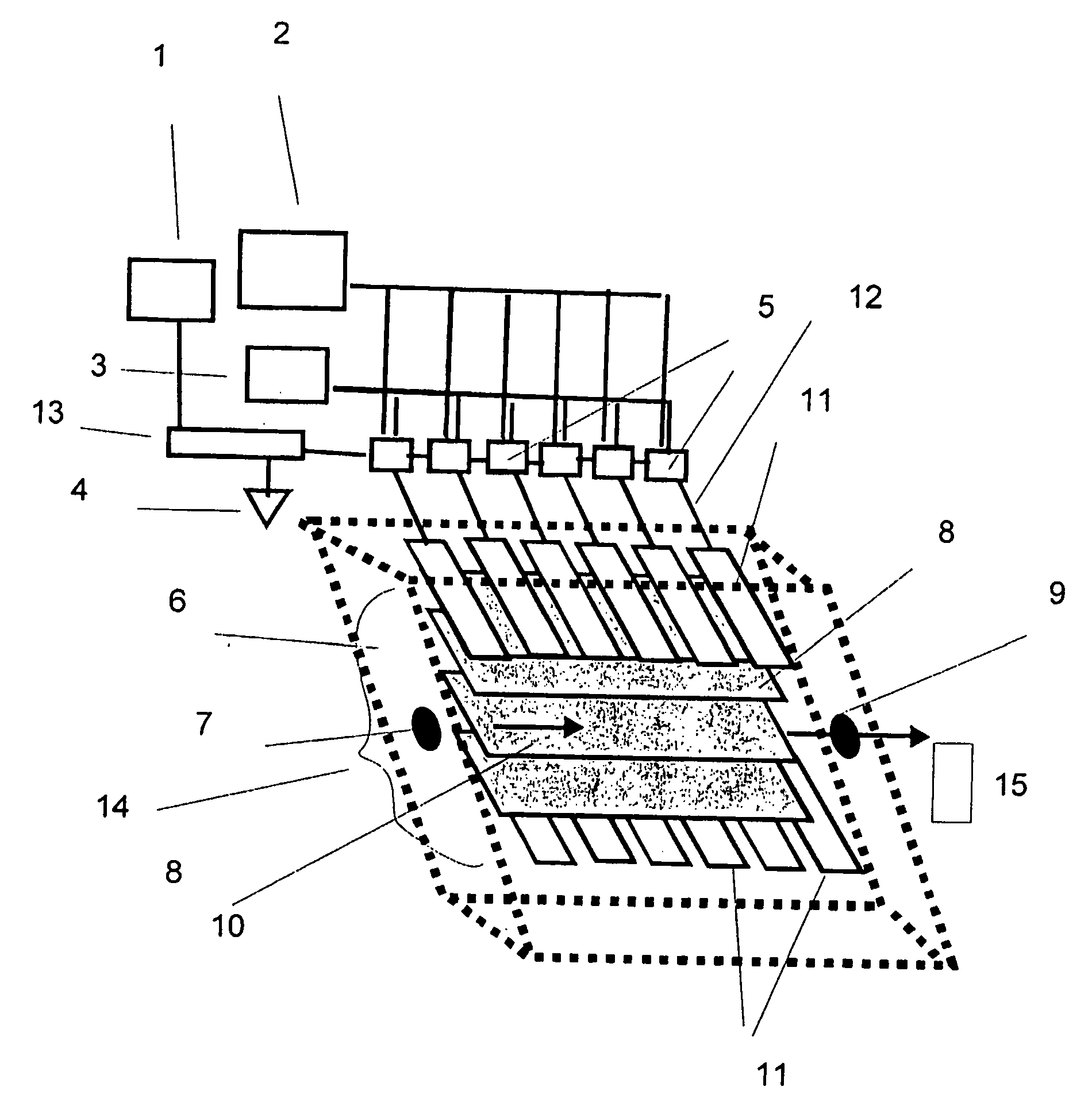

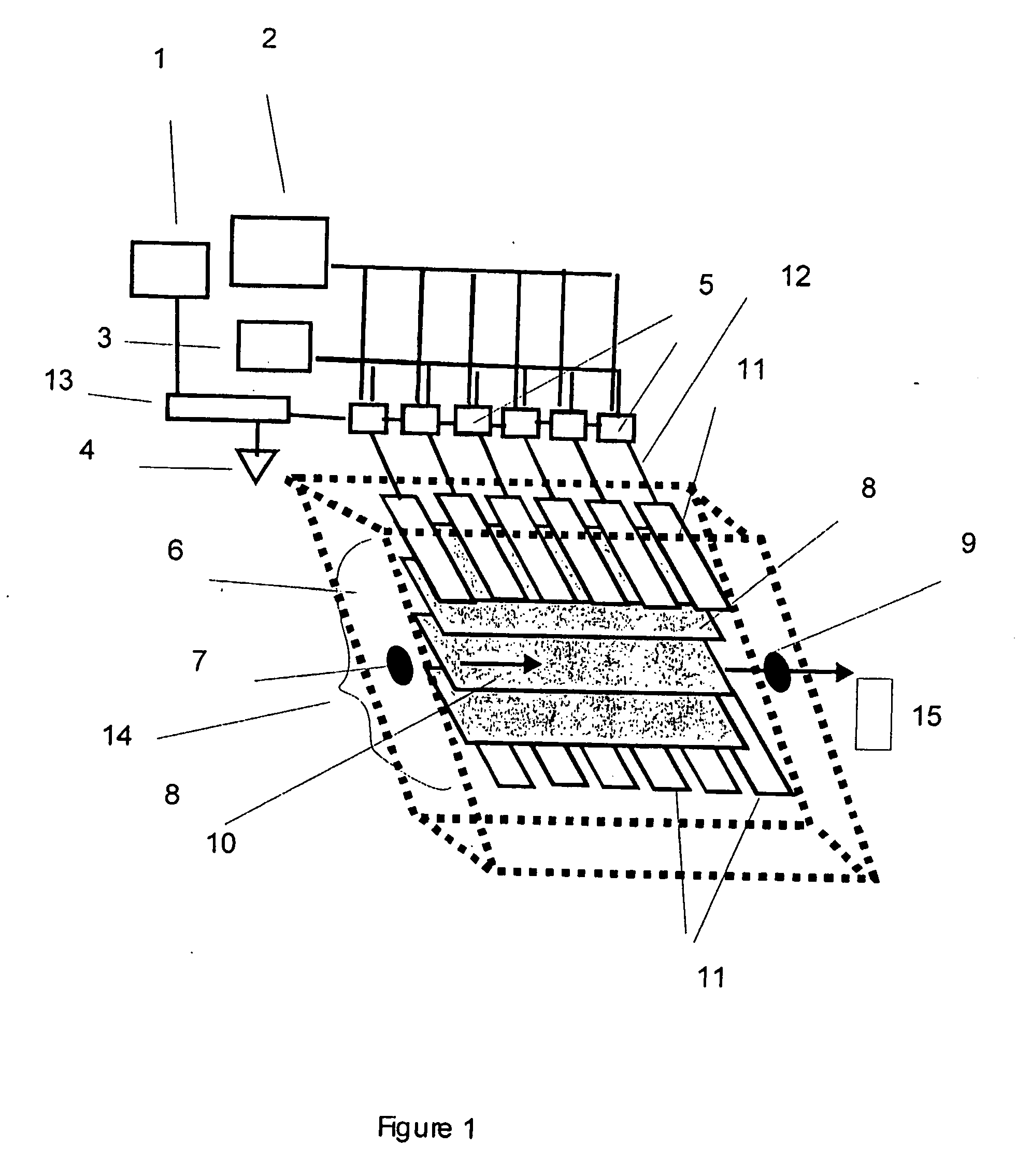

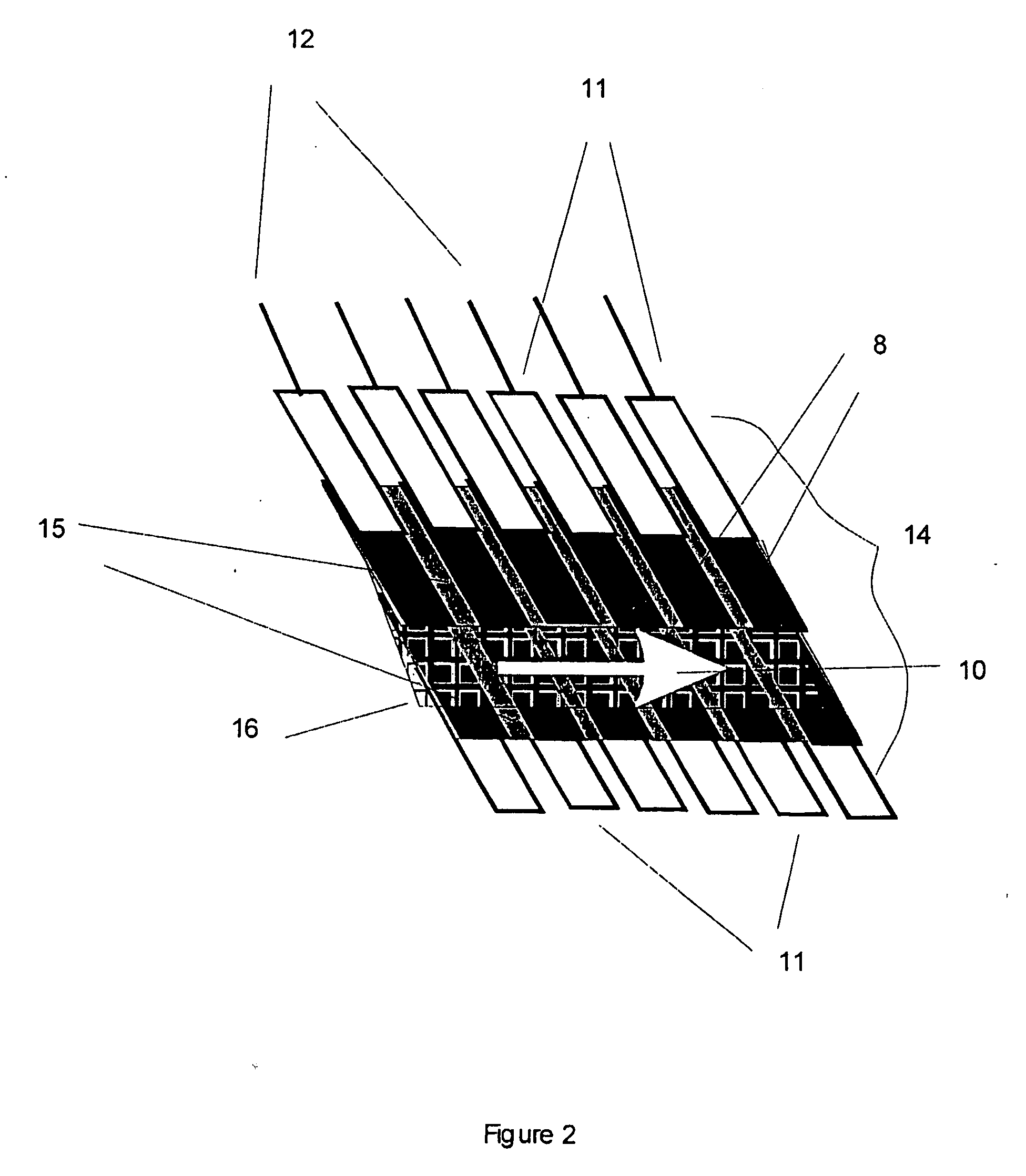

[0024]FIG. 1 is a schematic of an integrated stage flow-through capacitor cell and system of the present invention, showing a controller or logic means 1, a power supply 2, e.g., a capacitor power supply, a switch power supply 3, ground 4, switches, relays, or FETS, e.g., switches 5, a cartridge or cell holder 6 as a casing for one or more capacitor cells, inlet 7, electrode or electrode assembly 8, outlet 9, flow path 10, individual current collector 11, individual current collector lead 12, circuit 13, e.g., an integrated circuit, programmable logic chip, digital input / out, or printed circuit; cell assembly 14, and sensor 15. A computer or controller 1 and a additional digital input / output 13 controls and actuates switches, relays, or FETS 5 in either a pre-programmed or feed-back controlled sequence using conductivity, pH, or other composition data, or flow, amperage, or voltage data supplied to controller 1 by sensor 15. Switch 5 can be multiple switching, and can also be an int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| contact resistance | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com