Method for reducing brightness reversion of mechanical pulps and high-yield chemical pulps

a technology of mechanical pulp and brightness reversion, which is applied in the field of fibrous products, can solve the problems of reducing reflectivity, negative effect on other properties of products, or being uneconomical, and achieves the effect of improving brightness reversion and not significantly impaired by yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

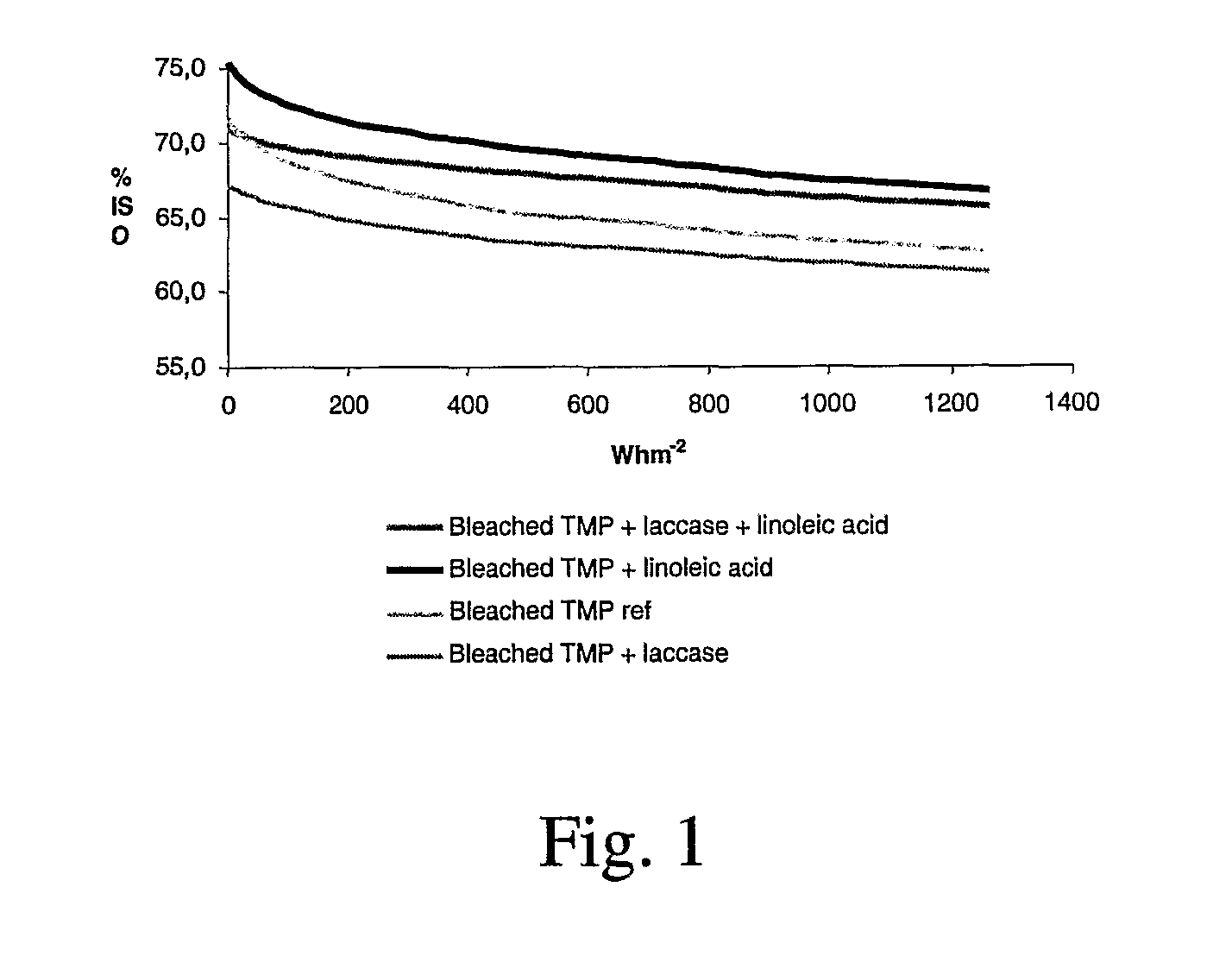

[0049] A 5 g portion of bleached spruce TMP was suspended in water. The pH of the suspension was adjusted to pH 4.5 by addition of acid. The suspension was stirred at RT. Laccase dosage was 1000 nkat / g of pulp dry matter and the final pulp consistency was 7.5%. After 30 minutes laccase reaction, 0.15 mmol linoleic acid / g of pulp dry matter was added to the pulp suspension. After 1 h total reaction time, the pulp suspension was filtered and the pulp was washed thoroughly with water. Handsheets were prepared. For comparison purposes, reference treatments were carried out using the same procedure as described above but without addition of laccase or linoleic acid or both. The light-fastness on the pulps was tested with Xenotest 150S light exposure and weathering test instrument using “window glass” filter. The brightness of the handsheets was measured as function of irradiation dosage. The results are presented graphically in FIG. 1.

[0050] From the results presented in FIG. 1, it is a...

example 2

Bonding of New Compounds to TMP

[0051] A 5 g portion of spruce TMP was suspended in water. The pH of the suspension was adjusted to pH 4.5 by addition of acid. The suspension was stirred at RT. Laccase dosage was 1000 nkat / g of pulp dry matter and the final pulp consistency was 7.5%. After 30 minutes laccase reaction the new compound was added to the pulp suspension. After 1 h total reaction time, the pulp suspension was filtered and the pulp was washed thoroughly with water. Handsheets were prepared. For comparison purposes, reference treatments were carried out using the same procedure as described above but without addition of laccase or the new compound. The light-fastness on the pulps was tested with Xenotest 150S light exposure and weathering test instrument using “window glass” filter. The changes in the ISO brightnesses after irradiation are summarized in Table 1.

TABLE 1Δ BrightnessIrradation(as ISO-Treatment(Whm2)Brightness)TMP Reference126010TMP + laccase + ferulic acid...

example 3

[0052] Sample A: Peroxide bleached aspen-CTMP-pulp was treated with sodium persulphate (dosage 5 kg / ton of pulp) and linoleic acid (5 kg) at 80° C., at pH 5 for 60 minutes. The treatment was carried out at a consistency of 10%.

[0053] Sample B: The pulp sample was treated in the same way as Sample A except that ammonium persulphate (5 kg) was used instead of Na-persulphate.

[0054] Sample C: The pulp sample was treated in the same way as Samples A and B except that hydrogen peroxide was used instead of persulphate. The pH of the test was 4.

[0055] Sample D: The pulp sample was treated as Sample A but t-butanol (5 kg) was used instead of linoleic acid.

[0056] Sample E: The pulp sample was treated in the same way as Sample A, but no linoleic was added. After the treatment with persulphate, a separate treatment was made with linoleic acid (5 kg) at 80° C. at a consistency of 10%. The duration of the treatment was 30 min, and the pH was 5

[0057] Sample F: The sample was prepared as Sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com