Polysaccharide compositions for use in tissue augmentation

a polysaccharide composition and tissue technology, applied in the field of tissue augmentation, can solve the problems of reducing affecting the implantation rate of the graft,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of 2.3% Sodium CMC Gel in Sterile Water.

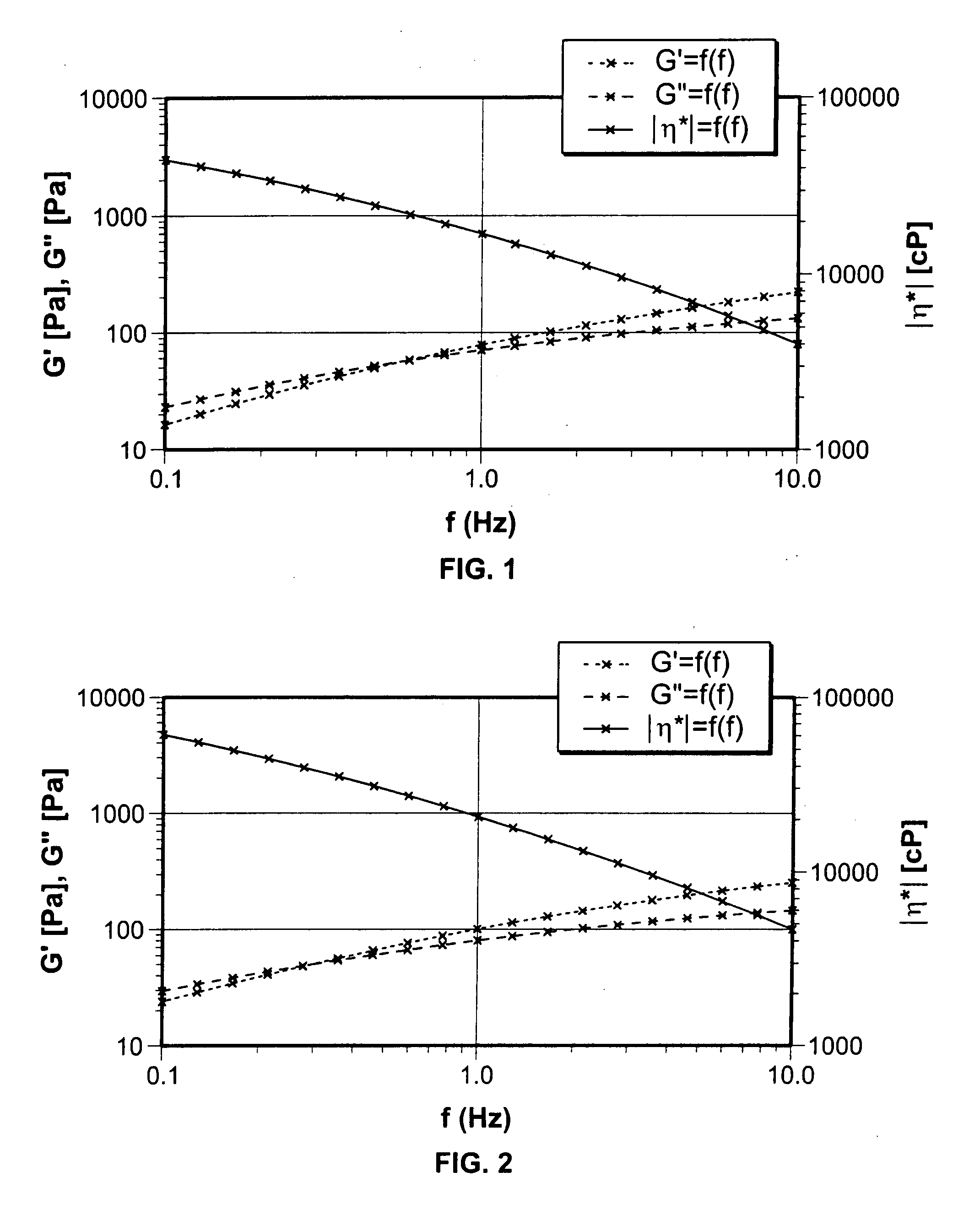

[0087] Sodium carboxymethylcellulose was prepared in sterile water for injection and adjusted to a pH of from about 7.1 to about 8.0 using potassium hydroxide. The dispersion was mixed in an orbital Ross mixer @1725 RPM for 5 minutes followed by mixing in an orbital Ross mixer @1725 RPM for 40 minutes. while holding a vacuum @ 26 mm Hg or more. The composition was then steam sterilization at 121 degrees C. for times ranging from 3 minutes to 30 minutes. In addition, one sample was sterilized for time intervals between 3 minutes and 30 minutes @ 121 degree C. Results are shown in FIG. 1 where G′ represents the elastic modulus, G″ represents the viscous modulus and η the complex viscosity. The profile shows that G′ and G″ intersect at 0.495 Hz (3.2 Rad / sec). Above this frequency, the composition exhibits non-newtonian solution characteristics (tan δ<1.0).

example 2

Preparation of 2.4% Sodium CMC Gel in Sterile Water.

[0088] Sodium carboxymethylcellulose was prepared in sterile water for injection and adjusted to a pH of from about 7.1 to about 8.0 using potassium hydroxide. The dispersion was mixed in an orbital Ross mixer @1725 RPM for 5 minutes followed by mixing in an orbital Ross mixer @1725 RPM for 40 minutes. while holding a vacuum @ 26 mm Hg or more. The composition was then steam sterilization at 121 degrees C. for times ranging from 3 minutes to 30 minutes. In addition, one sample was sterilized for time intervals between 3 minutes and 30 minutes @ 121 degree C. Results are shown in FIG. 2 where G′ represents the elastic modulus, G″ represents the viscous modulus and η the complex viscosity. The profile shows that G′ and G″ intersect at 0.0299 Hz (1.8 Rad / sec) (lower frequency than that shown in FIG. 1). Above this frequency, the composition exhibits non-Newtonian solution characteristics (tan δ<1.0).

example 3

Preparation of 2.5% Sodium CMC Gel in Sterile Water.

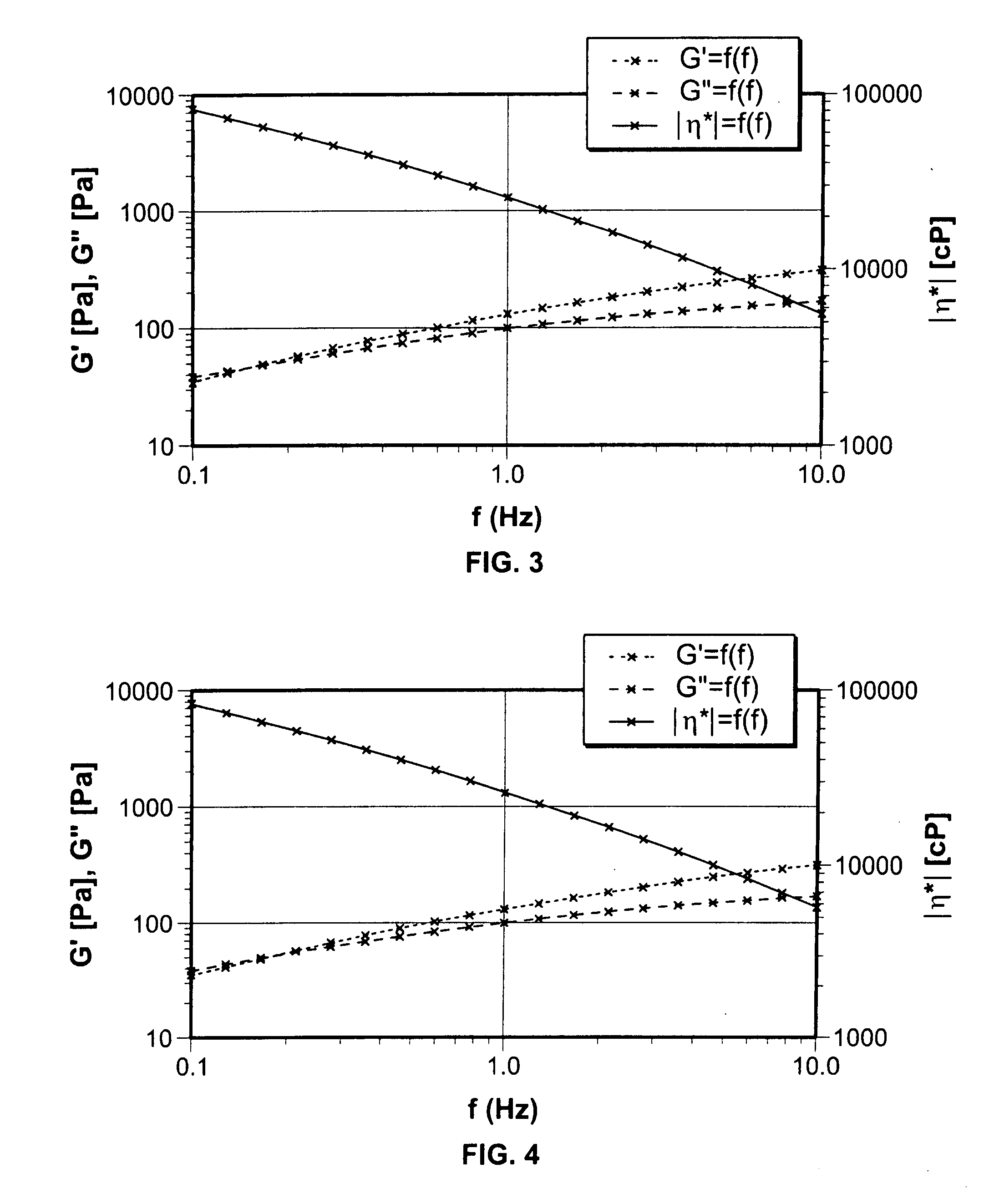

[0089] Sodium carboxymethylcellulose was prepared in sterile water for injection and adjusted to a pH of from about 7.1 to about 8.0 using potassium hydroxide. The dispersion was mixed in an orbital Ross mixer @1725 RPM for 5 minutes followed by mixing in an orbital Ross mixer @1725 RPM for 40 minutes. while holding a vacuum @ 26 mm Hg or more. The composition was then steam sterilization at 121 degrees C. for times ranging from 12 minutes to 30 minutes. In addition, one sample was sterilized for time intervals between 3 minutes and 12 minutes @121 degree C. Results are shown in FIG. 3 where G′ represents the elastic modulus, G″ represents the viscous modulus and η the complex viscosity. The profile shows that G′ and G″ intersect at 0.157 Hz (1 rad / sec) frequency than shown in FIGS. 1 and 2. Above this frequency, the composition exhibits non-Newtonian solution characteristics (tan δ<1.0).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com