Biocompatible self-lubricating polymer compositions and their use in medical and surgical devices

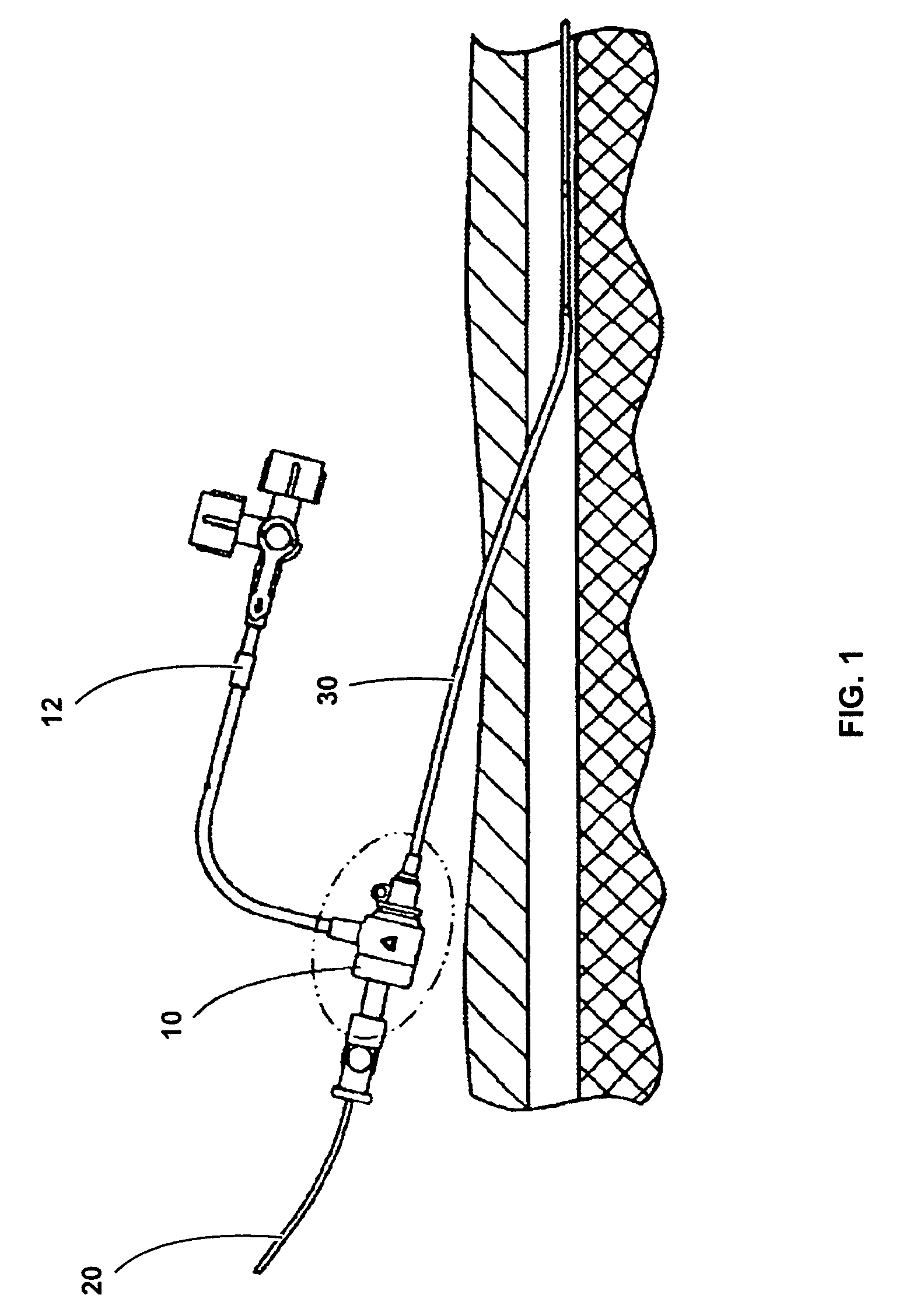

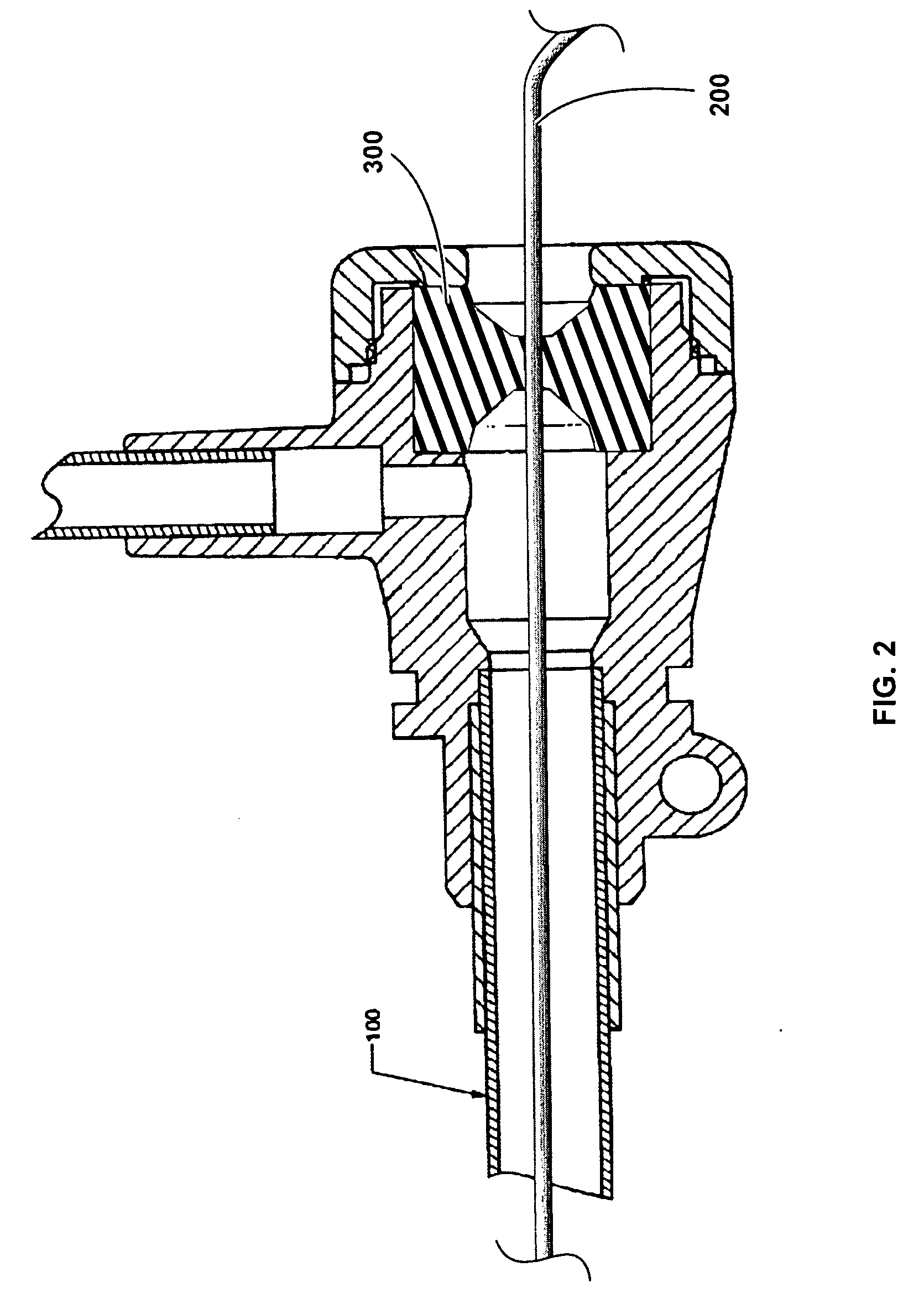

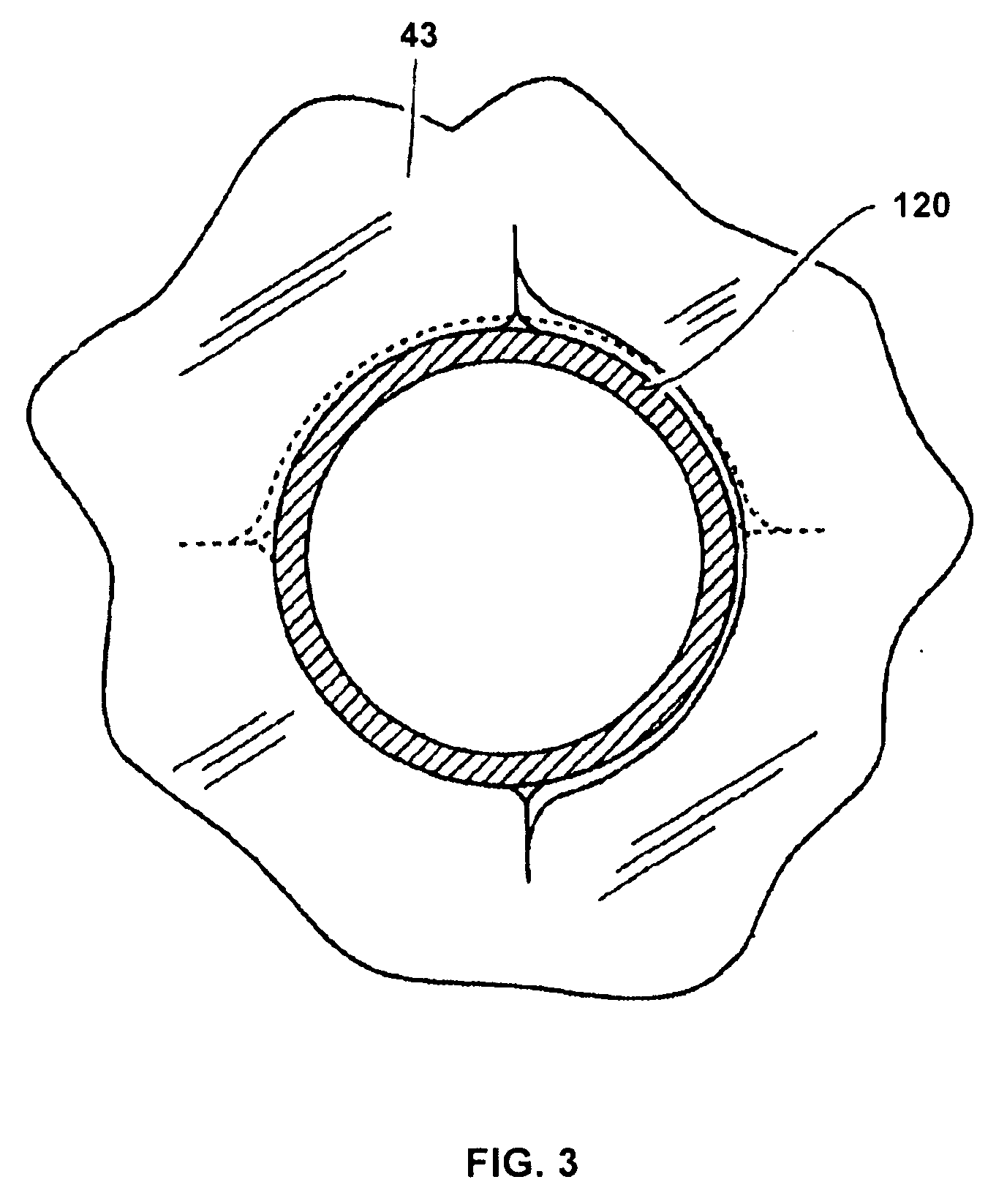

a self-lubricating, polymer composition technology, applied in the field of biocompatible self-lubricating polymer compositions and their use in medical and surgical devices, can solve the problems of lack of control, degree of friction, need for forceful insertion or withdrawal, etc., to achieve effective reduction of friction between rubbing or contact surfaces, enhanced lubricity polymer compositions, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0035]A silicone elastomer resin based upon methylvinyl silicone (Silastic Q7-4735) is selected as the polymer matrix. A liquid lubricant, PFPE synthetic oil, is used at 5 parts per hundred of rubber (phr). The components are mixed using a two-roller mill. The resulting compound is transfer-molded into the gaskets of a hemostasis valve, as noted above, and then post-cured at 150 degrees C. for 2 hours.

example 2

[0036]The same polymer resin as Example 1, but a liquid lubricant (PFPE synthetic oil) is used at 10 phr.

example 3

[0037]The same polymer resin as Example 1, but a solid lubricant (low molecular weight PTFE micropowder) is used at 3 phr, and a liquid lubricant (PFPE synthetic oil) is used at 5 phr.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com