Methods for manufacturing heat sink having relatively high aspects ratio thereof

a technology of heat sink and aspect ratio, which is applied in the direction of manufacturing tools, semiconductor/solid-state device details, transportation and packaging, etc., can solve the problems of high defective rate of manufactured heat sink b>10/b>, time-consuming whole procedure, etc., and achieve high aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]As aforementioned, the relatively better performance of the heat sinks could be achieved by increasing the aspect ratio of the heat sink through a tooling procedure for manufacturing the die 5 with a relatively high surface hardness, a specific inner hardness, a specific surface friction and a specific toughness so as to stand a relatively high pressure and achieve a relatively high aspect ratio of the heat sink 30 (see FIGS. 4(a)-4(d)).

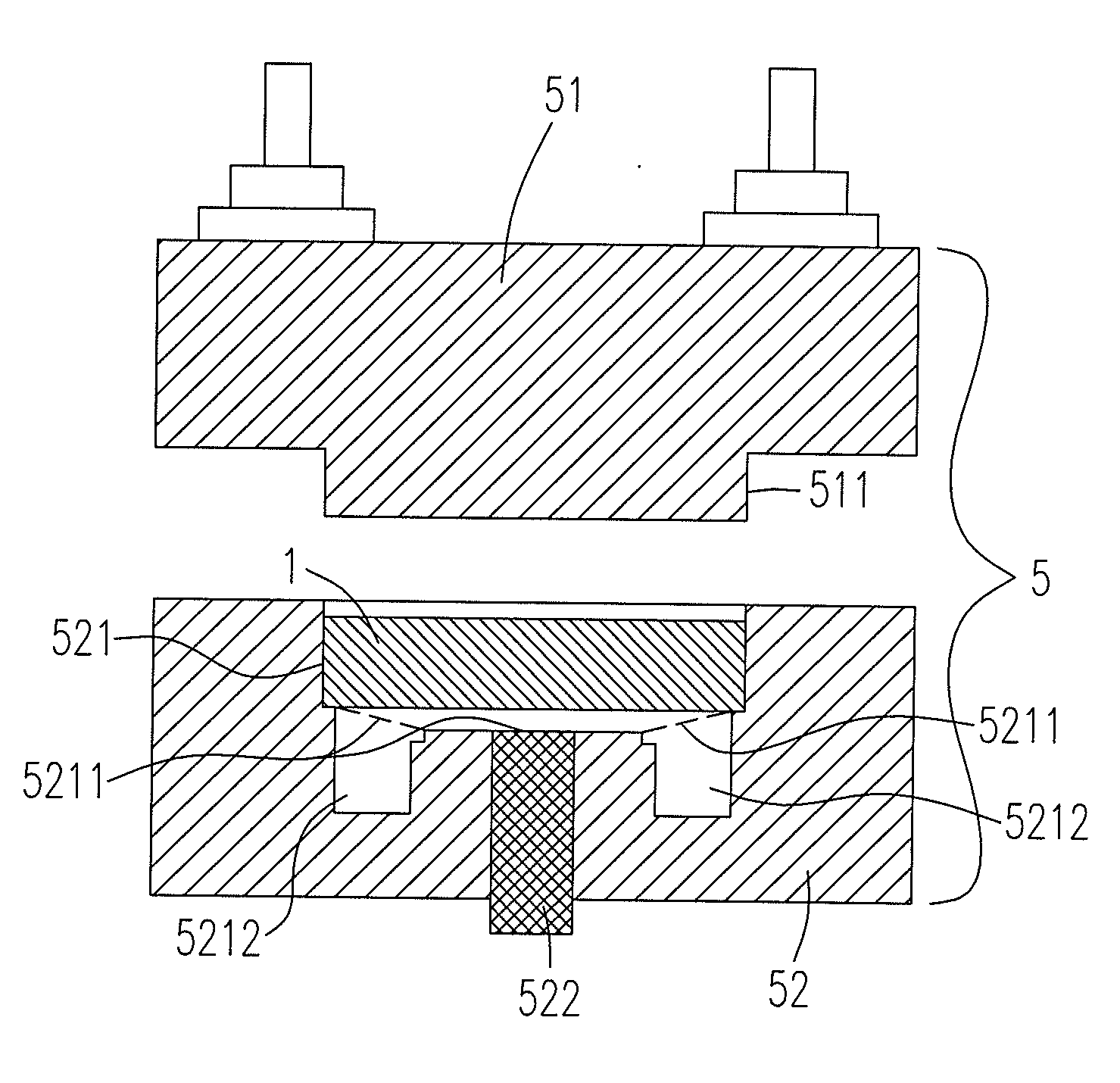

[0050]Please refer to FIGS. 4(a)-4(d), the first proposed method for manufacturing a heat sink 30 having a central cavity 31, a taper core 32, a plurality of fins 33 and a base plate 34 integrally formed with the taper core 32 and the fins 33 includes the steps of: (a) making a die 5 having a relatively high surface hardness, a specific inner hardness, a specific surface friction and a specific toughness so as to stand a relatively high pressure and achieve a relatively high aspect ratio of the heat sink; (b) putting a material 1 into the die 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

| Ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com