Environmentally compatible integrated food and energy production system

a food and energy production system technology, applied in the direction of energy input, combustion types, lighting and heating apparatuses, etc., can solve the problems of agricultural runoff, adversely affecting water quality in the country, and requiring significant amounts of land to operate ,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

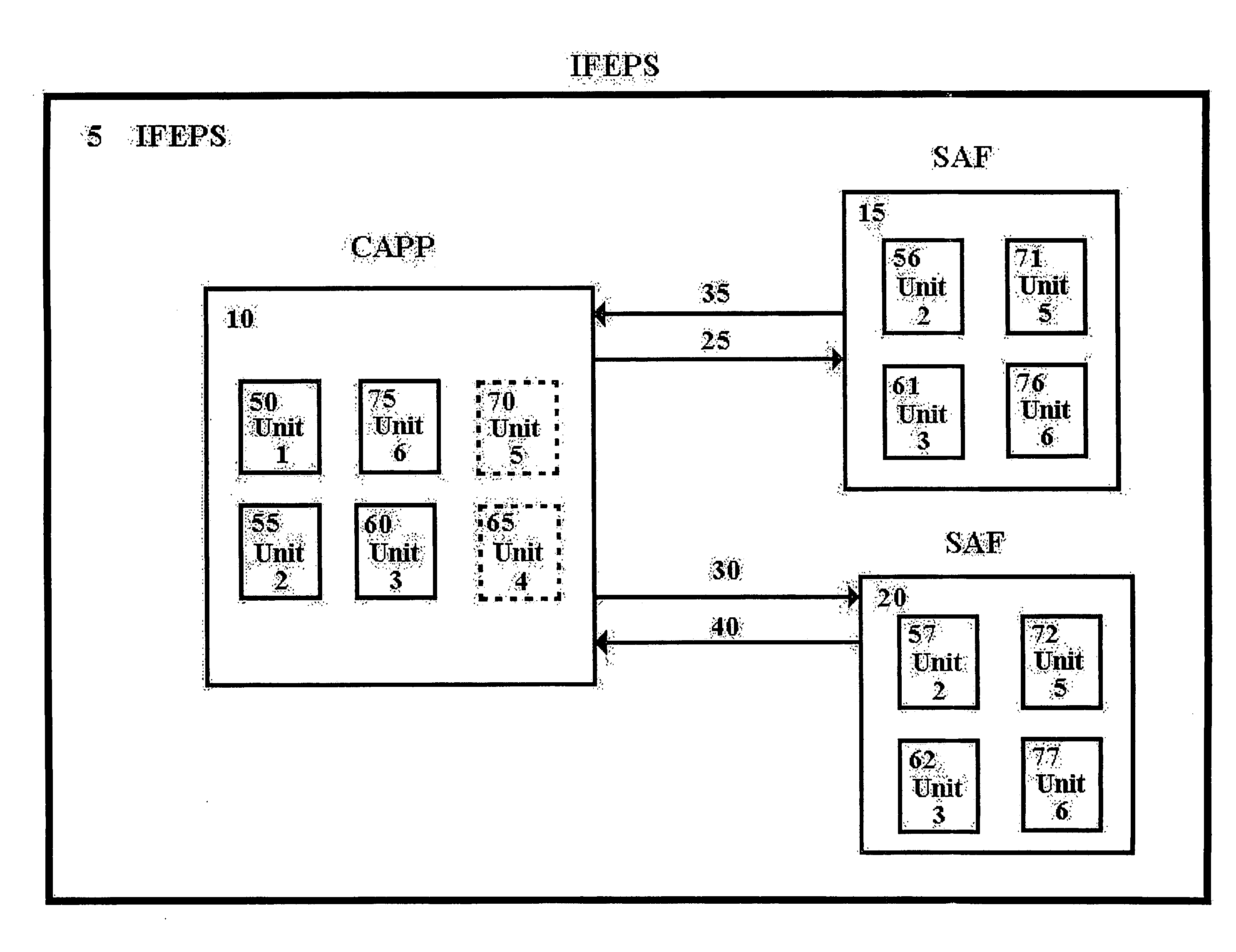

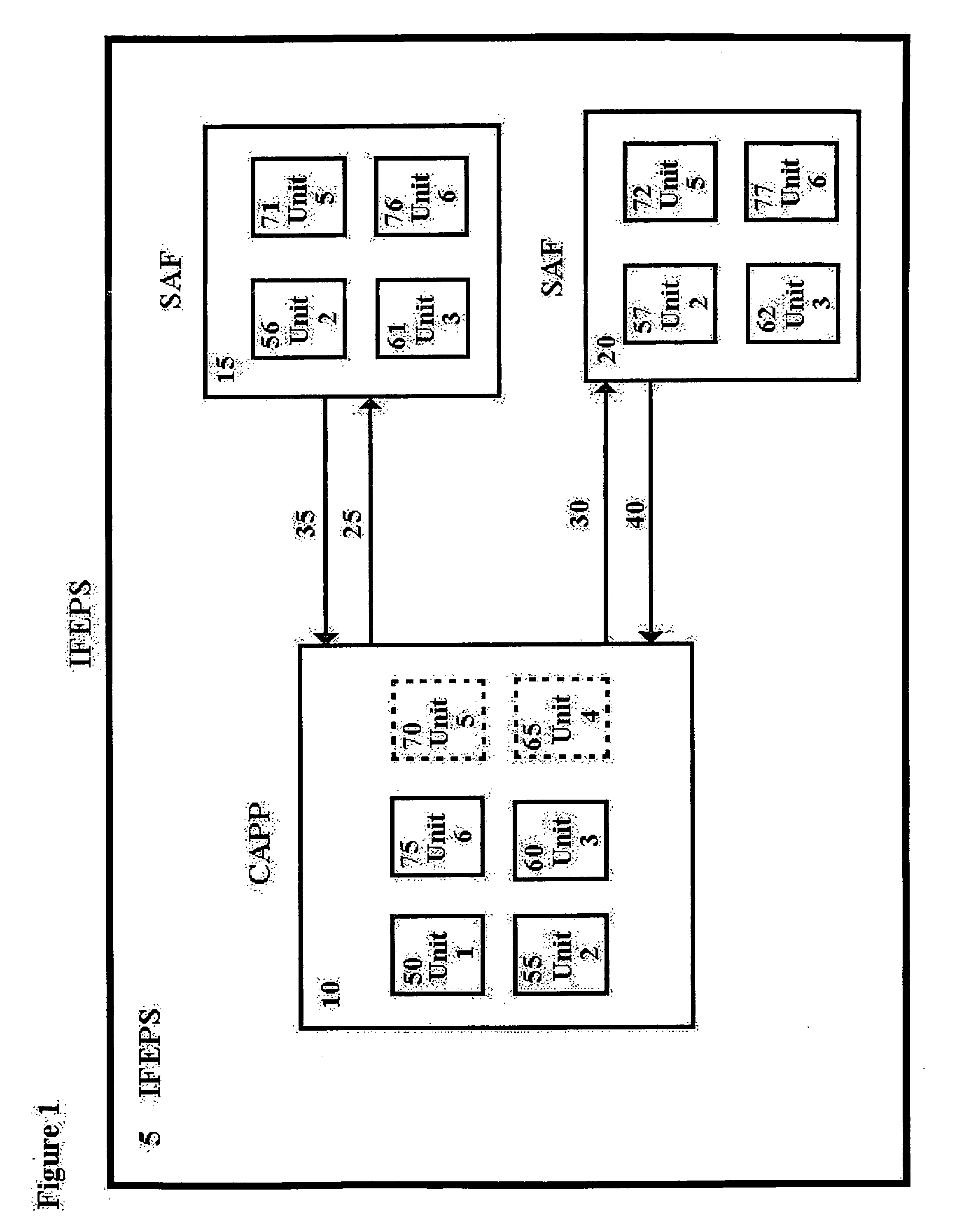

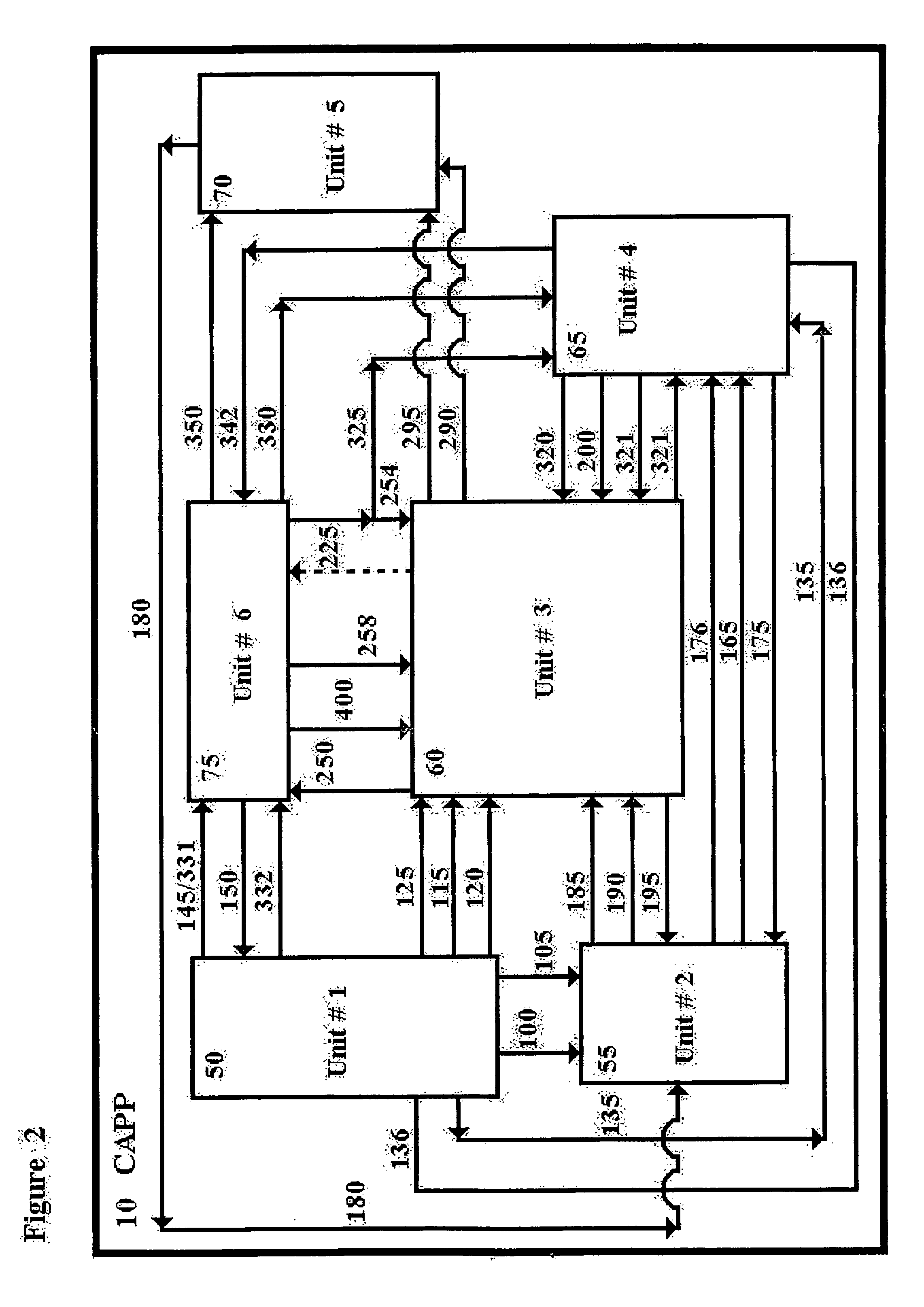

[0073]The present invention relates to the collection of food and energy production units with attendant processing units into an integrated system capable of substantially boosting the efficiency and economics of food and energy production while greatly reducing the impact on the environment. In a preferred embodiment of the invention, the system and process further includes sufficient land area for crop production and uptake of nutrients and water.

[0074]The definitions and nomenclature provided below are used to help describe the invention.

DEFINITIONS

IFEPS—Integrated Food and Energy Production System

[0075]A collection of processing and production units integrated to take advantage of shared resources of products and energy in and between units, typically where the units are within a limited geographical location (perhaps, for example, about a five to ten mile radius).

Unit—Functional Unit

[0076]A major component of the IFEPS, whose operation contributes a principle processing and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com