Cell electrode and electrochemical cell therewith

a cell electrode and electrode active material technology, applied in the field of cell electrodes and electrochemical cells therewith, can solve the problems of insufficient long-term stability under high temperature atmosphere, accelerated deterioration, and aggravated deterioration, so as to prevent peroxidation-perreduction deterioration of an electrode active material, improve cycle properties, and improve electrode performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

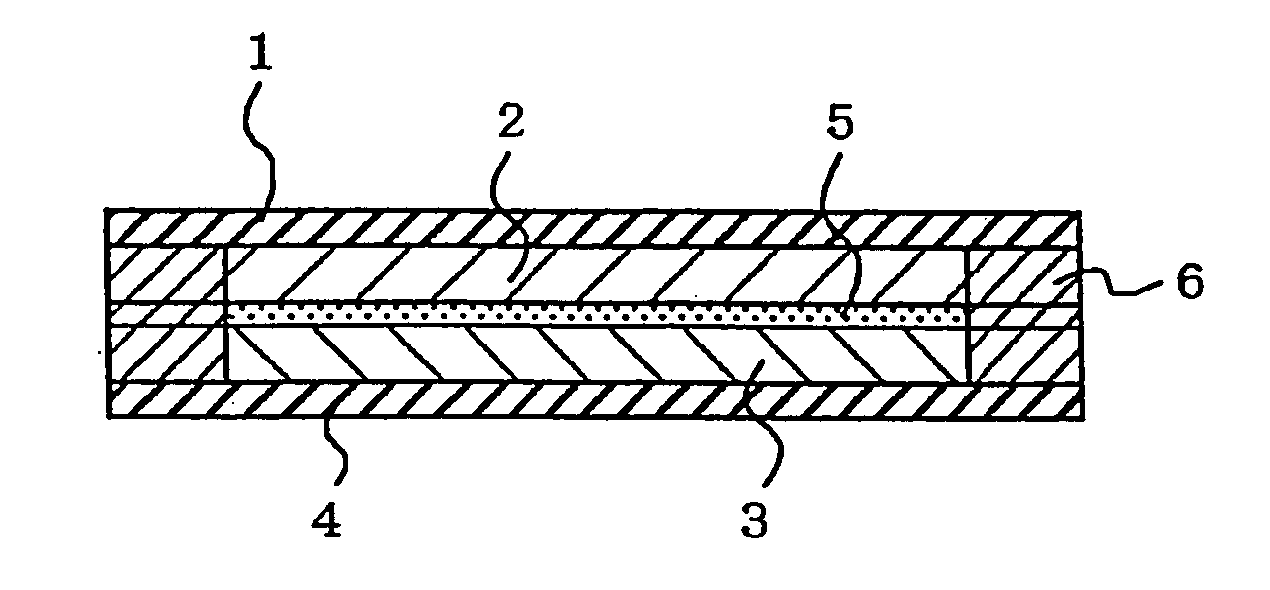

Image

Examples

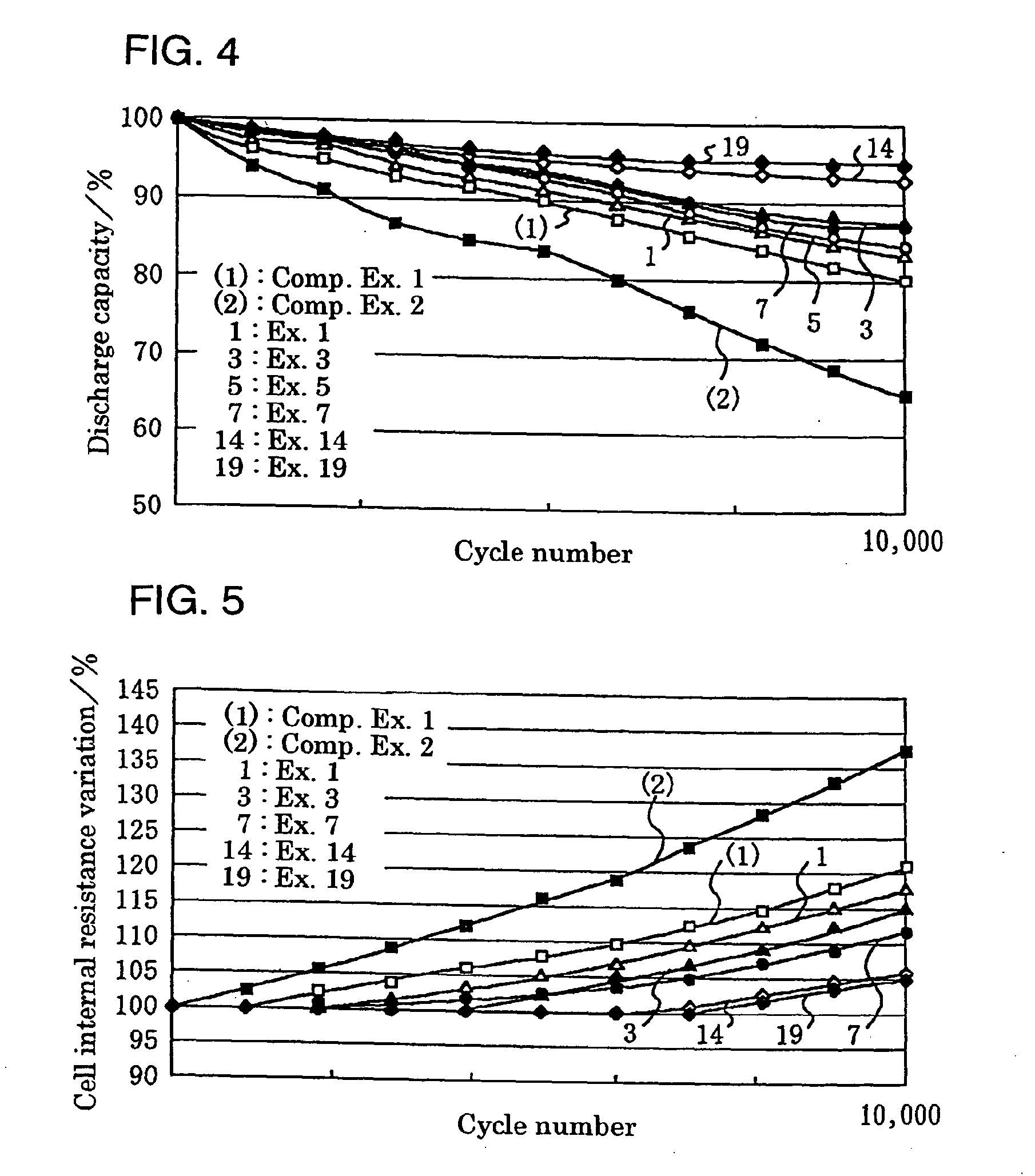

example 1

[0071] A positive electrode used was prepared as follows. To indole trimer 69 wt % as an active material were added 23 wt % of vapor growth carbon (VGCF) as a conductive auxiliary and 8 wt % of a polyfluorovinylidene (average molecular weight: 1100) as an electrode molding component. To 100 wt % of the mixture was added 5 wt % of imidazole. The resultant mixture was stirred and blended in a blender and then molded by a hot press into a solid electrode having a desired size, which was used as a positive electrode 2.

[0072] A negative electrode used was prepared as follows. To polyphenylquinoxaline 75 wt % as an active material were added 25 wt % of carbon black (K.B.600) as a conductive auxiliary. To 100 wt % of the mixture was then added 5 wt % of imidazole. The resultant mixture was stirred and blended in a blender and then molded by a hot press into a solid electrode having a desired size, which was used as a negative electrode 3.

[0073] An electrolytic solution used was a 20 wt %...

example 2

[0076] A positive electrode was prepared as described in Example 1 without adding imidazole. A negative electrode was prepared as described in Example 1 except adding 20 wt % of imidazole. A battery was formed as described in Example 1, except these electrodes were used.

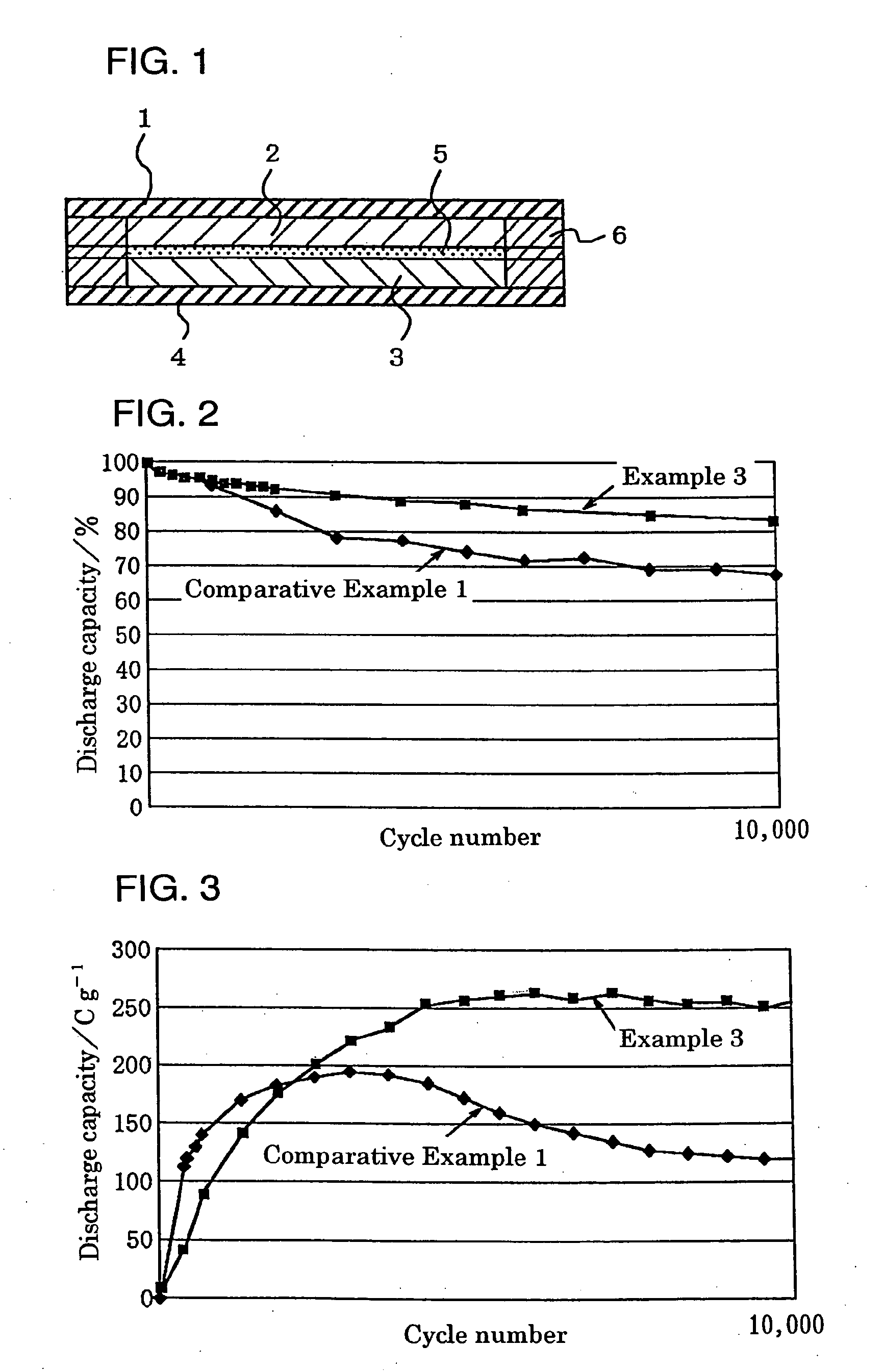

example 3

[0077] A positive electrode was prepared as described in Example 1 except adding 20 wt % of imidazole. A negative electrode was prepared as described in Example 1 except adding 20 wt % of imidazole. A battery was formed as described in Example 1, except these electrodes were used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

| wt % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com