Process for producing coal liquids and use of coal liquids in liquid fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

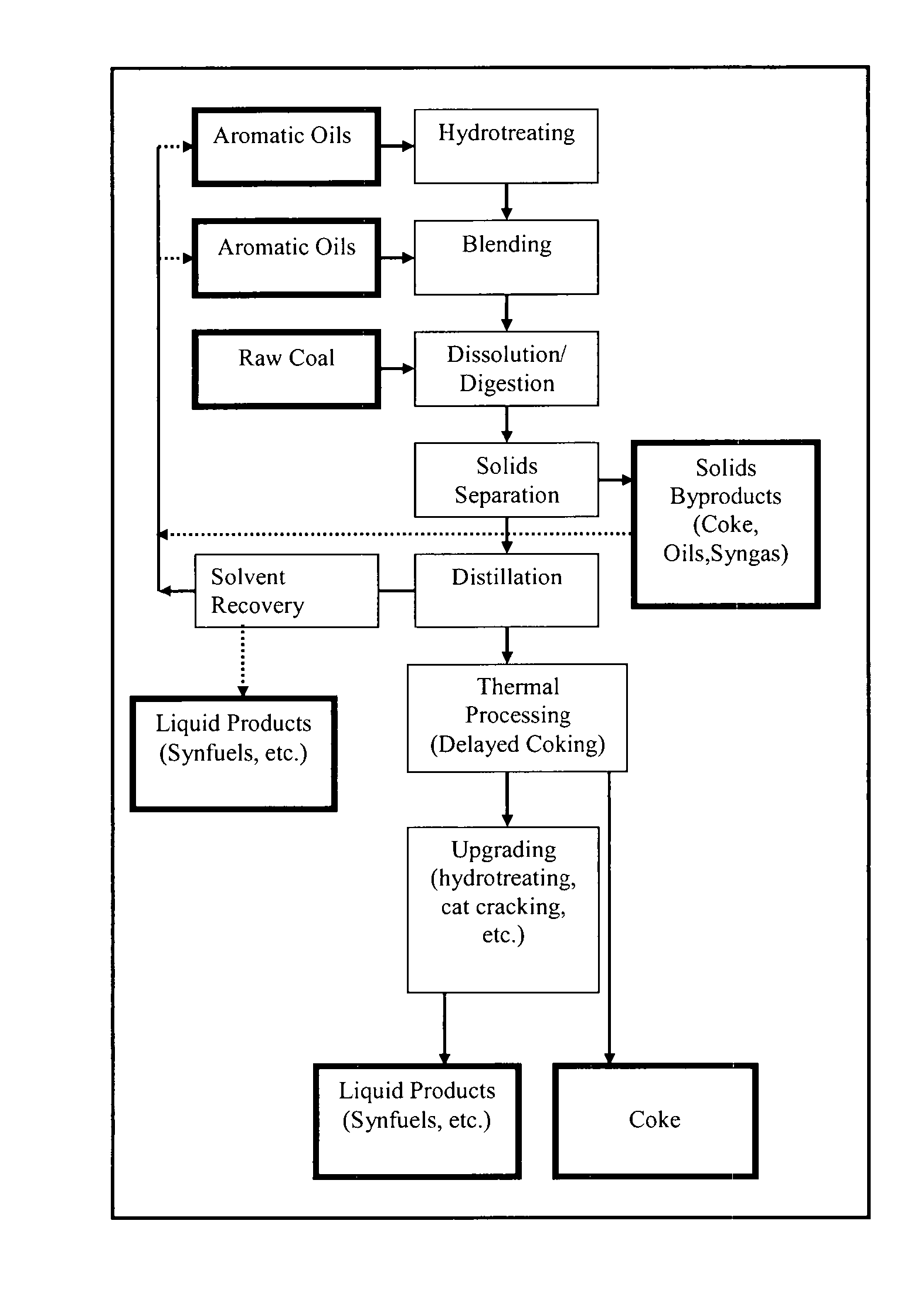

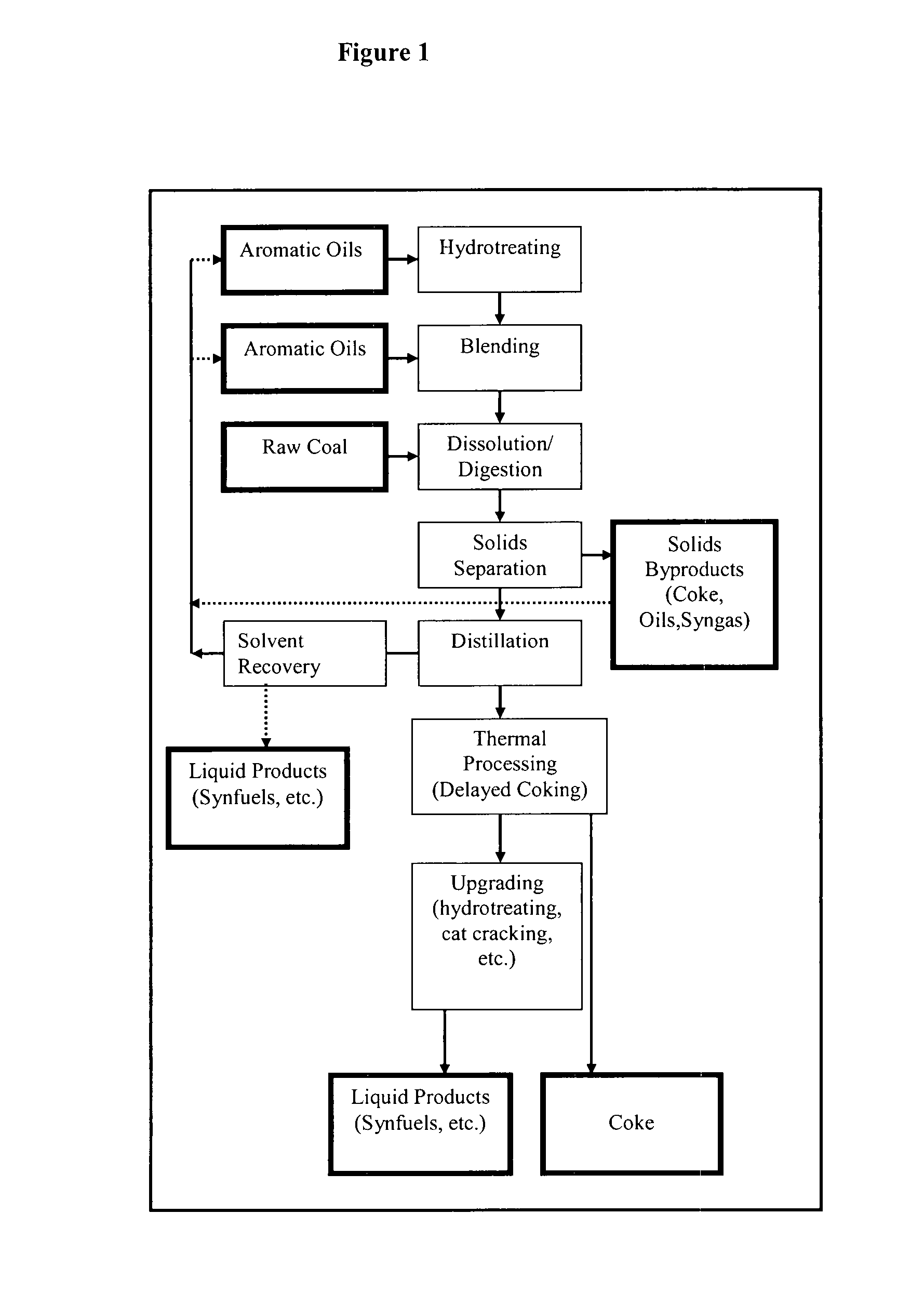

Image

Examples

Embodiment Construction

[0019] The invention relates to the ability to make a gasoline substitute similar to Ethanol-85, composed of about 85% ethanol and about 15% petroleum, with the petroleum components replaced with coal-derived counterparts. Coal derived is the use of any source of coal such as coal tar, liquefied coal, or other coal liquids. Coal liquids are much more soluble in ethanol than in gasoline and ethanol is clean burning which helps to prevent unburned aromatic hydrocarbons from persisting in the exhaust. This result is due to the combustion efficiency of ethanol which minimizes the emission of aromatic partially-combusted hydrocarbons found in the exhaust.

[0020] Coal liquids can optionally be blended with 10-95% alcohol to create a motor fuel with high octane rating and compatible combustion kinetics. In a blend, a higher percentage content of aromatic molecules can be tolerated from the coal liquids, than would be the case if coal liquids were the only component used. Coal liquids are h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com