Flex-rigid wiring board

a wiring board and rigid technology, applied in the field of wiring boards, can solve the problems of delayed signal propagation, more serious delay in signal propagation, and unstable high-speed signal transmission, and achieve the effect of stable signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

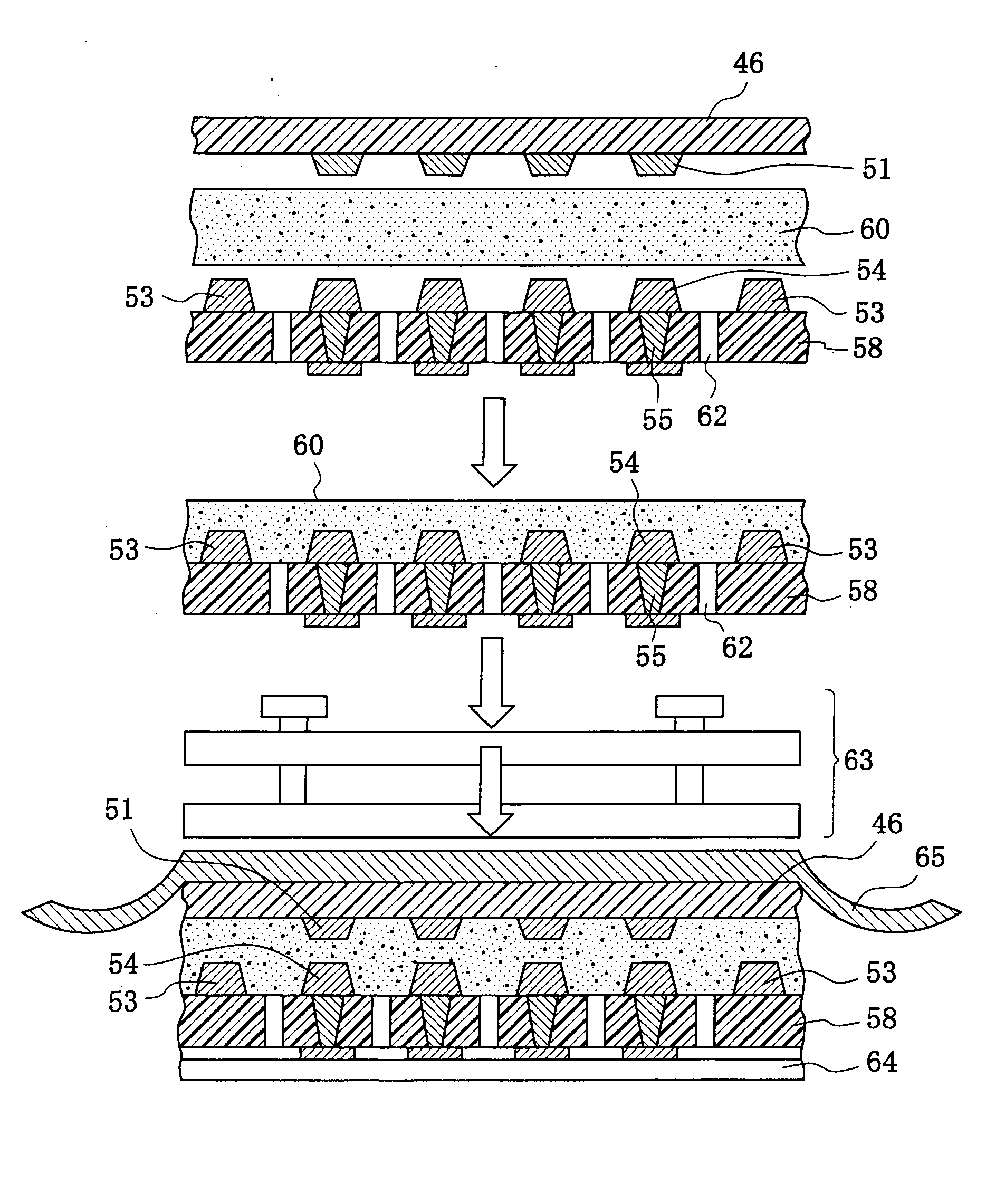

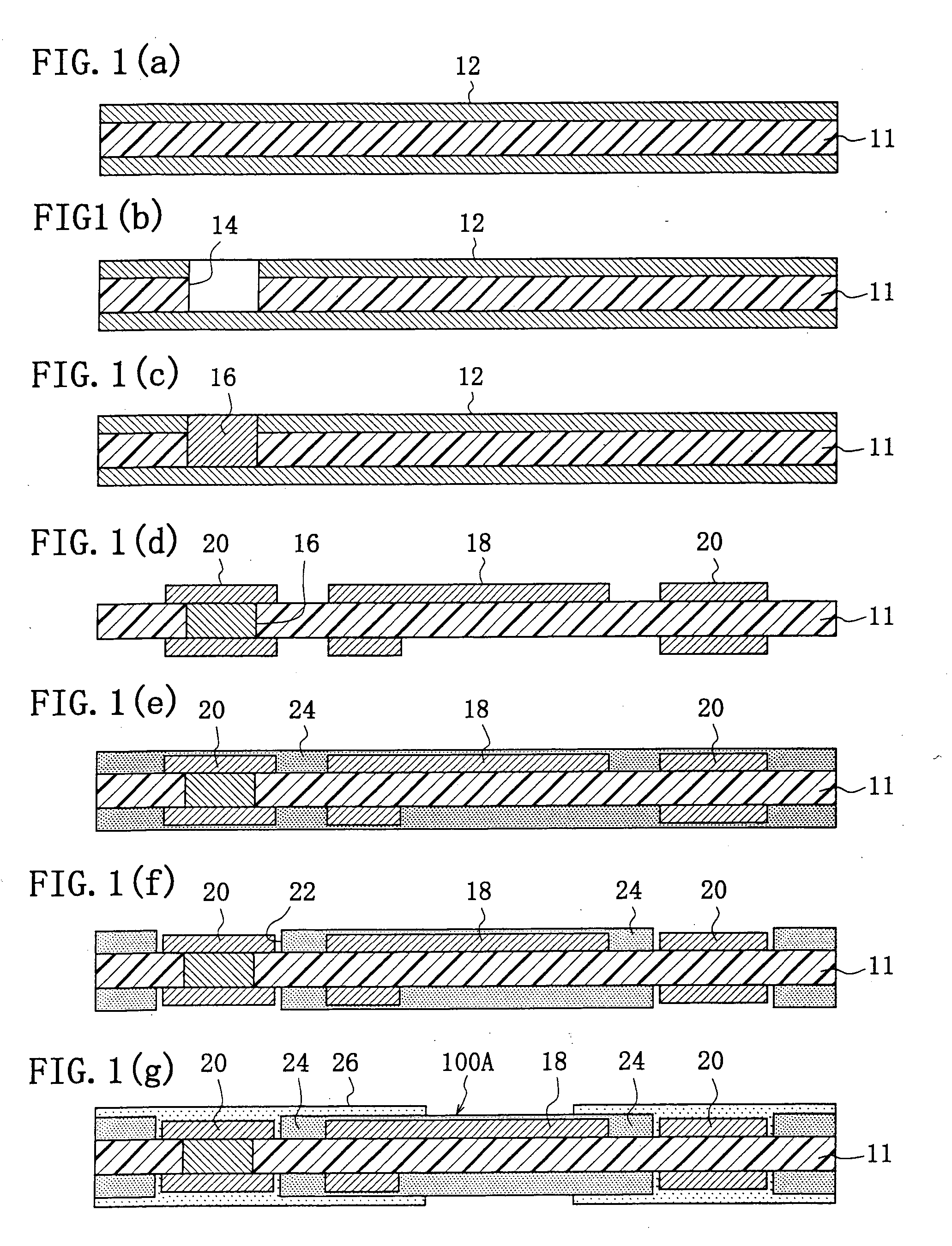

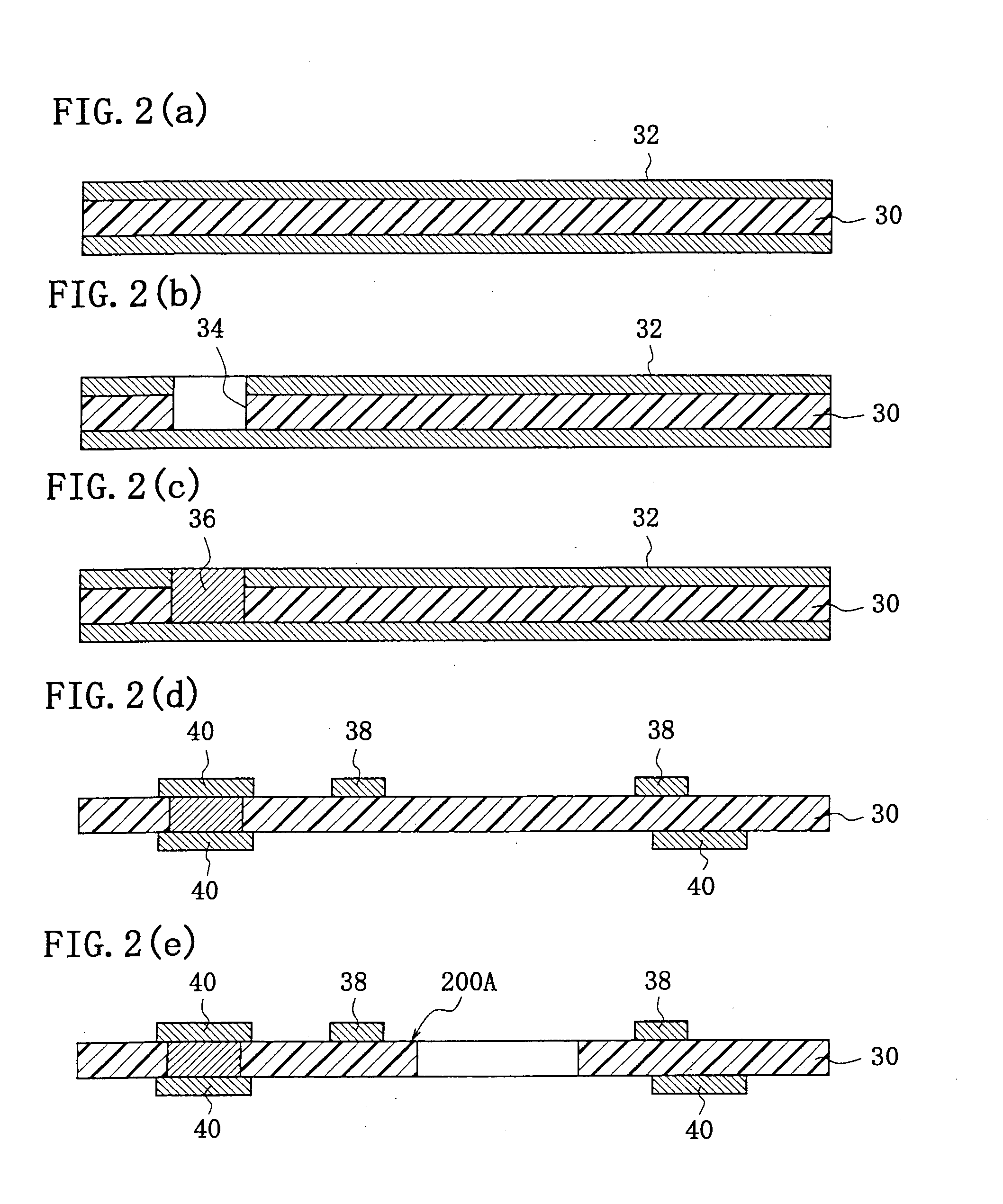

example 1

[0117] (A) Preparing a Flexible Substrate

[0118] (1) For producing the flex-rigid wiring board as the example 1 of the present invention, a laminated film (ESPANEX SB by Shin-Nittetsu Chemicals) formed from a 25 μm-thick insulative film 11 of polyimide resin having a 30 μm-thick copper foil 12 laminated on either side thereof (as in FIG. 1(a)) is used as a base material for preparation of a flexible substrate 100A included in the flex-rigid wiring board.

[0119] (2) A resist layer is formed on the copper foil on the laminated film, and exposed to light and developed to form a circular opening of 300 μm in diameter. The copper foil was etched using a cupric chloride aqueous-solution to form the opening in the copper foil. Carbon-dioxide laser or the like is irradiated to the opening to form an opening 14 that penetrates the resin layer to the copper foil on the back of the insulative film (as in FIG. 1(b)).

[0120] (3) The opening 14 formed in the step (2) above is fully filled with co...

example 2

[0137] A flex-rigid wiring board is produced similarly to the aforementioned example 1 except that each coverlay 24 formed on the flexible substrate 100A is formed to a thickness of 25 μm.

example 3

[0138] A flex-rigid wiring board is produced similarly to the example 1 except that each coverlay 24 formed on the flexible substrate 100A is formed to a thickness of 40 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com