Environmental control system with adsorption based water removal

a technology of environmental control system and water removal, which is applied in the field of air conditioners, can solve the problems of insufficient ecs, ecs therefore has to be oversized or require higher inlet pressure, and the type of system is inherently more complex and may be heavier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

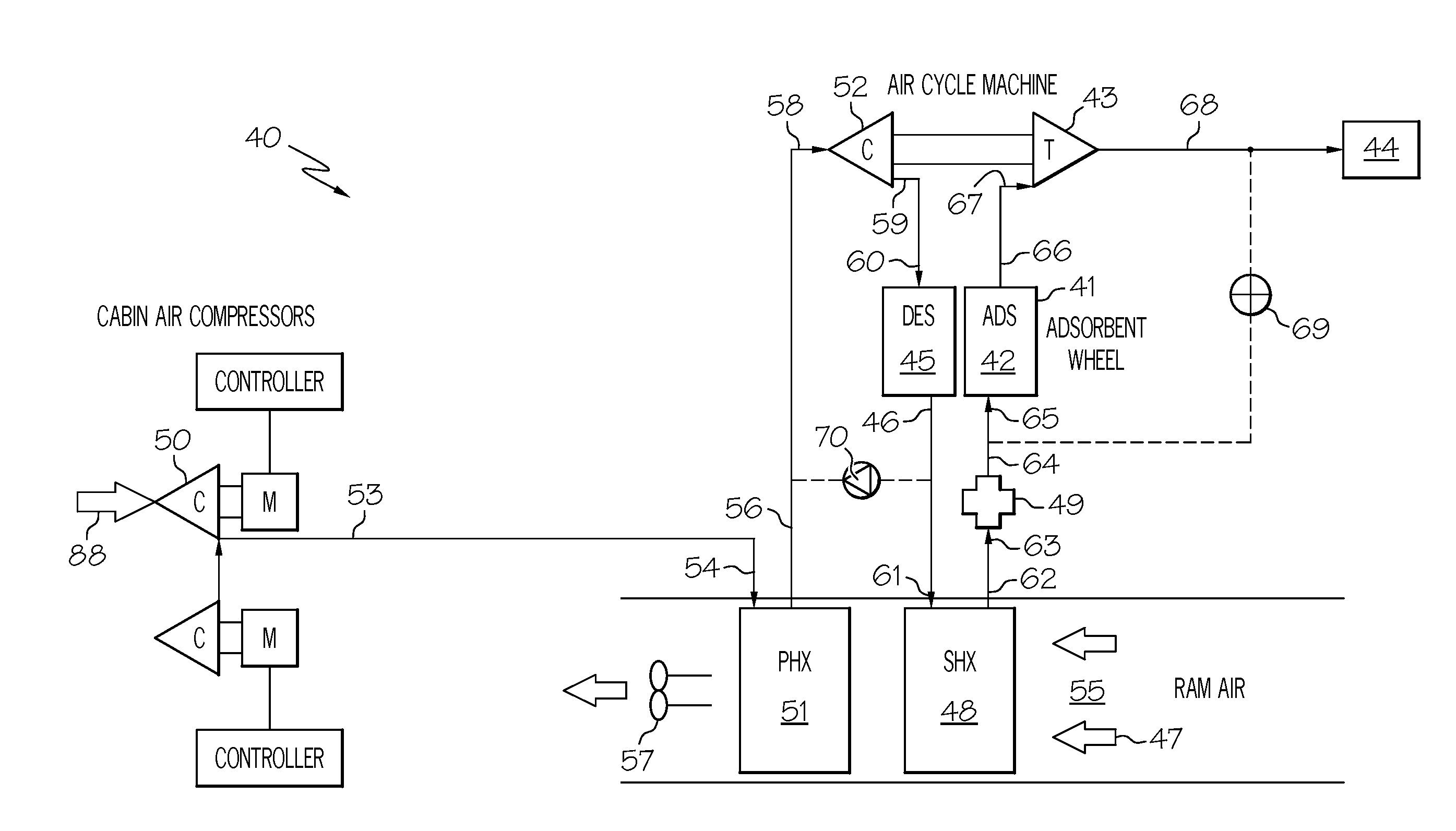

example 1

[0087]For an aircraft ECS with ambient inlet moisture of 133 g / lb and a 103° F. ambient temperature, an adsorbent sub-system 41 comprising an adsorbent wheel can deliver a water content of 213 g / lb to a high pressure water extractor (high pressure water separation sub-system 85), 80 g / lb above that of a traditional state-of-the-art system. At a temperature of 119° F. achieved by cooling the moist stream in air heat exchange with ambient air and at a pressure of 62.8 psia, the extractor can extract 91 g / lb of the entrained condenser water. The adsorbent wheel captures 80 g / lb out of the remaining water vapor, leaving 41 g / lb, an acceptable supply level, to the turbine 43 and the enclosure 44. The turbine 43 at 60.8 psia and 193.5° F. from the adsorbent wheel delivers 24.3° F. DB / 9.1° F. DAR at 41 g / lb, representing a cooling capacity of 44.5 kW to a 75° F. enclosure based on DAR temperature and a system air flow of 160 lb / min. The air supply system (air supply sub-system50) for that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com