Ferritic heat resistant steel

a heat resistant steel and ferritic technology, applied in the field of ferritic heat resistant steel, can solve the problems of not being able to improve the creep-fatigue strength of heat resistant steels, and achieve the effect of excellent high-temperature long-term creep strength and creep-fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

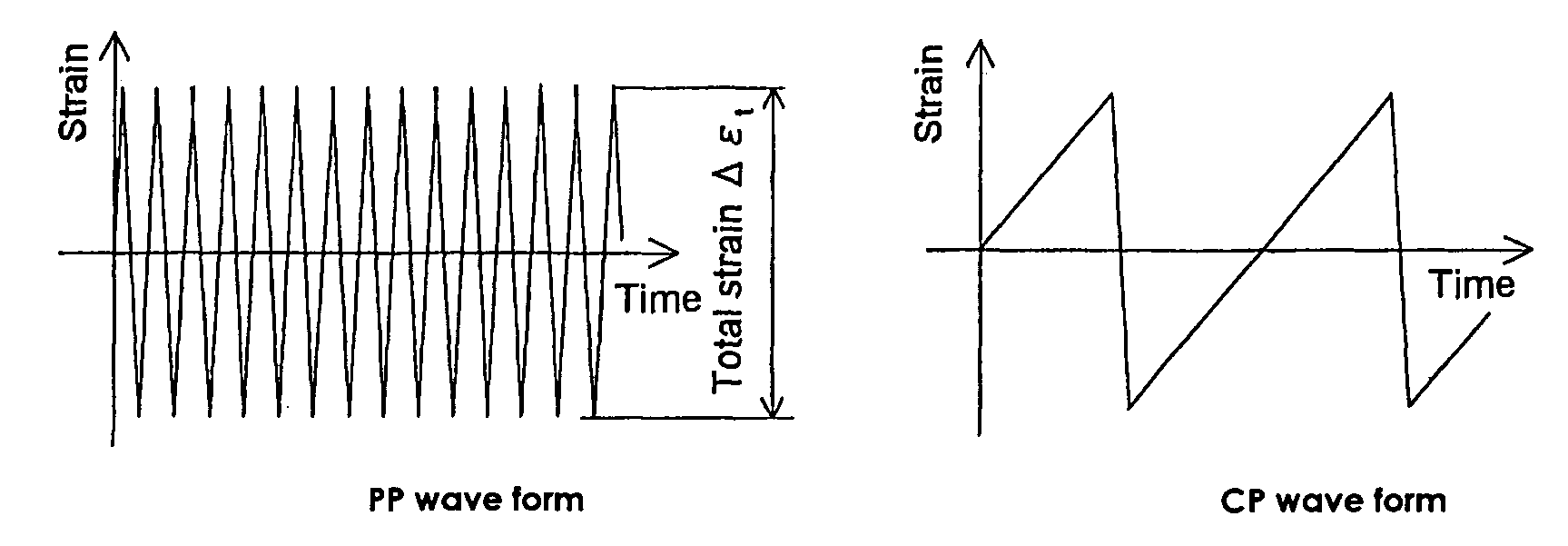

Method used

Image

Examples

examples

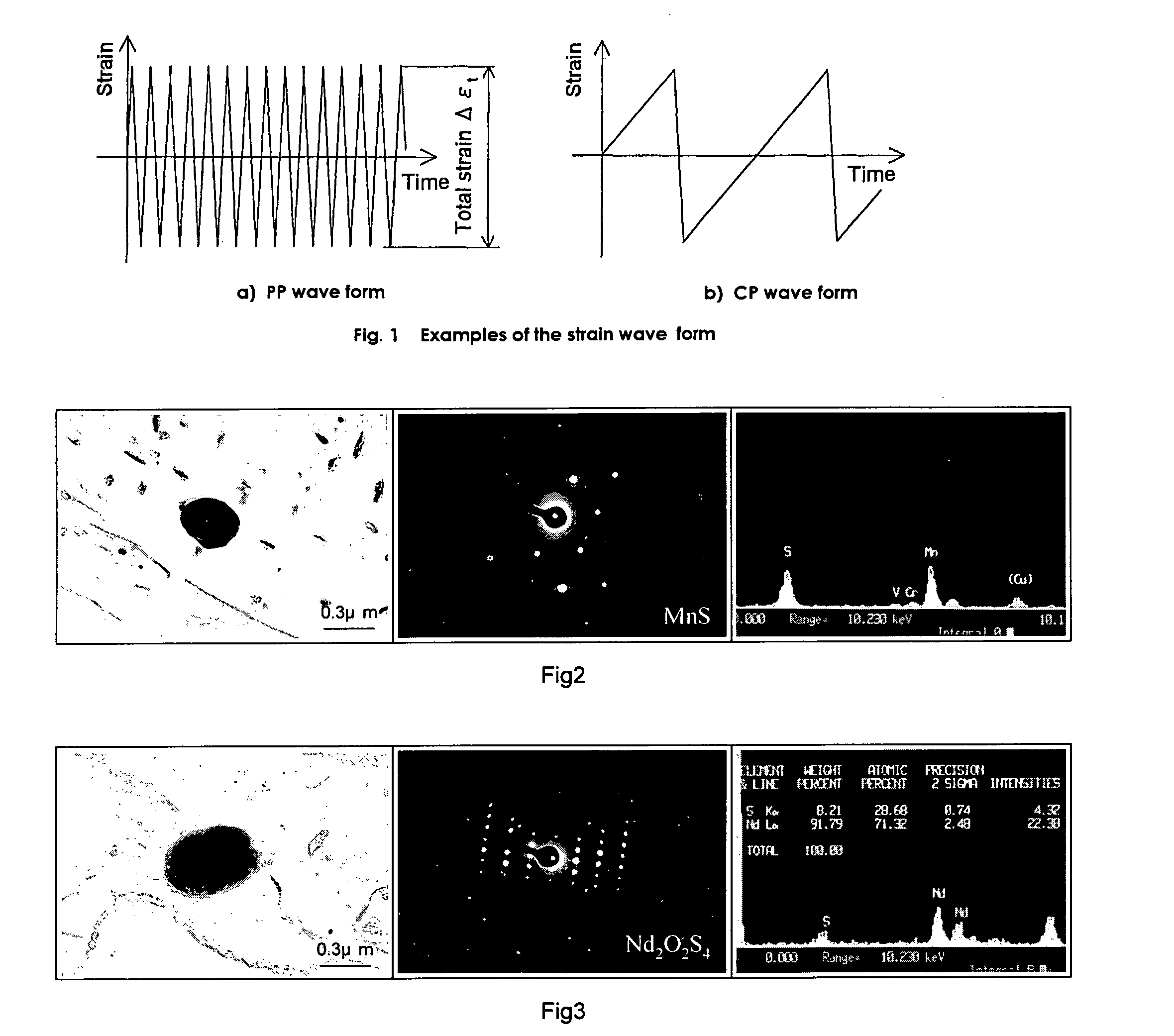

[0090] Steel species having the respective chemical compositions specified in Table 1 were produced by melting, using a vacuum induction melting furnace, and 50 kg ingots with a diameter of 144 mm, were prepared from each steel species. The steels given the symbols A to M are the steels according to the present invention, and those given the symbols 1 to 22 are steels for comparison. The steels given the symbols A to M and the symbols 15 to 20 were sufficiently deoxidized with C, Si, Mn and Al and, then, Nd was added just prior to casting. In the steel having the symbol 21, Nd was added at the start of melting and, in the case of the steel having the symbol 22, deoxidation was carried out using only carbon and then Nd was added.

[0091] These ingots were subjected to hot forging and hot rolling to produce 20 mm-thick plates, which were then maintained at a temperature of 1050° C. for 1 hour and then air-cooled (AC). The plates were further tempered by maintaining the temperature at 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| creep-fatigue life | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com