Packaging Solutions

a technology for packaging solutions and ophthalmic devices, applied in the directions of transportation and packaging, detergent compounding agents, cleaning compositions of lenses, etc., can solve the problems of reducing shelf life and/or adverse reactions, limited use of surfactants in packaging solutions, and many people who wear contact lenses still experience dryness or eye irritation, so as to preserve the sterility of the solution and the ophthalmic devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

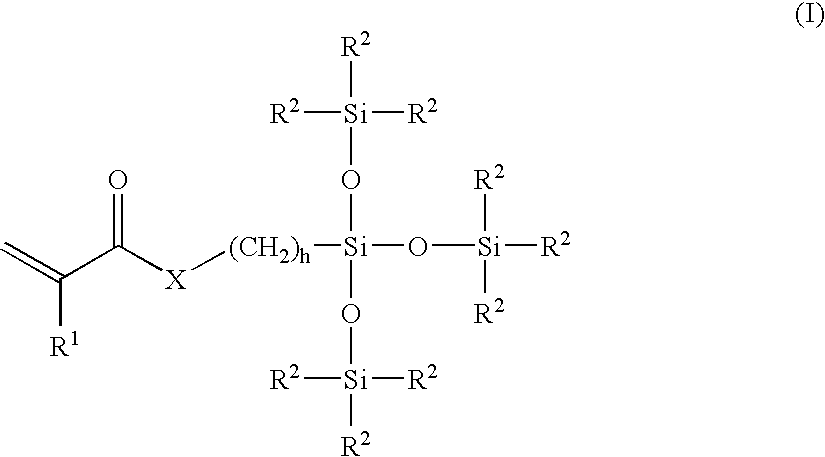

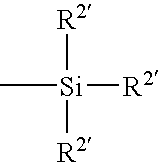

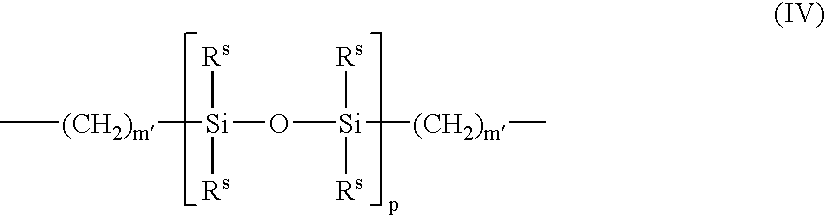

Method used

Image

Examples

example 1

[0076]Lens casting of a polyurethane-siloxane hydrogel formulation

[0077]Silicone hydrogel lenses were prepared from the monomer mixture set forth below in Table 1. The monomer mixture was filtered, cast between anterior and posterior polypropylene mold parts and then cured under UV for 1 hour. After being released from the molds, the lenses were extracted with isopropanol overnight, and then hydrated in deionized (DI) water.

TABLE 1FormulationPrepolymerExample 1I4D5S4H 53 parts by weightTRIS 15 parts by weightDMA 9 parts by weightHEMA 5 parts by weightNVP 24 parts by weightHEMAVC 1.3 parts by weightn-Hexanol 10 parts by weightD1173 0.5 parts by weightIMVT0.015 parts by weight

example 2

[0078]Surface treatment with hyaluronic acid sodium salt solution.

[0079]An aqueous solution containing 0.5% by weight of hyaluronic acid sodium salt (HA) (hyaluronic acid sodium salt from Streptococcus equi, commercially available from Fluka Biochemika, having a total impurity content of less than 1% protein and a solubility of 5 mg / ml in water) was prepared, and the pH was adjusted to 4 using dilute hydrochloric acid. The lenses prepared in accordance with Example 1 were then placed in glass vials, filled with the aqueous treating solution containing 0.5% by weight HA. Next, the lenses were autoclaved for 1 cycle (121° C., 30 minutes) and kept at 45° C. for 24 hours. The lenses were taken out and shaken with large amounts of DI water and then saved in a borate buffer saline for testing. The lenses thus obtained were visually examined and appeared more wettable than the control lens. The lenses were also rubbed between fingers and felt more lubricious than the control lens. The cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com