Method for producing carbon nanotubes, method for producing liquid dispersion thereof and optical product

a carbon nanotube and optical product technology, applied in the field of dispersible carbon nanotube production methods, can solve the problems of difficult to obtain a liquid dispersion with good dispersion properties, difficult to stabilize time-consuming treatment, etc., to achieve the effect of improving the dispersibility of single-walled carbon nanotubes, improving the dispersibility of carbon nanotubes, and improving the dispersion of carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

UV Ozone Treatment

[0060]Single-walled carbon nanotubes (1 to 2 nm in diameter and 5 to 30 μm in length, manufactured by Cheap Tubes, Inc.) were subjected to UV treatment in the air for 60 minutes using a UV ozone treatment system (applying ultraviolet light with wavelengths of 184.9 nm and 253.7 nm, manufactured by SAMCO, Inc.). The treatment was performed while ozone was generated by the UV irradiation. The integrated quantity of light was 162 J / cm2.

Preparation of Liquid Dispersion

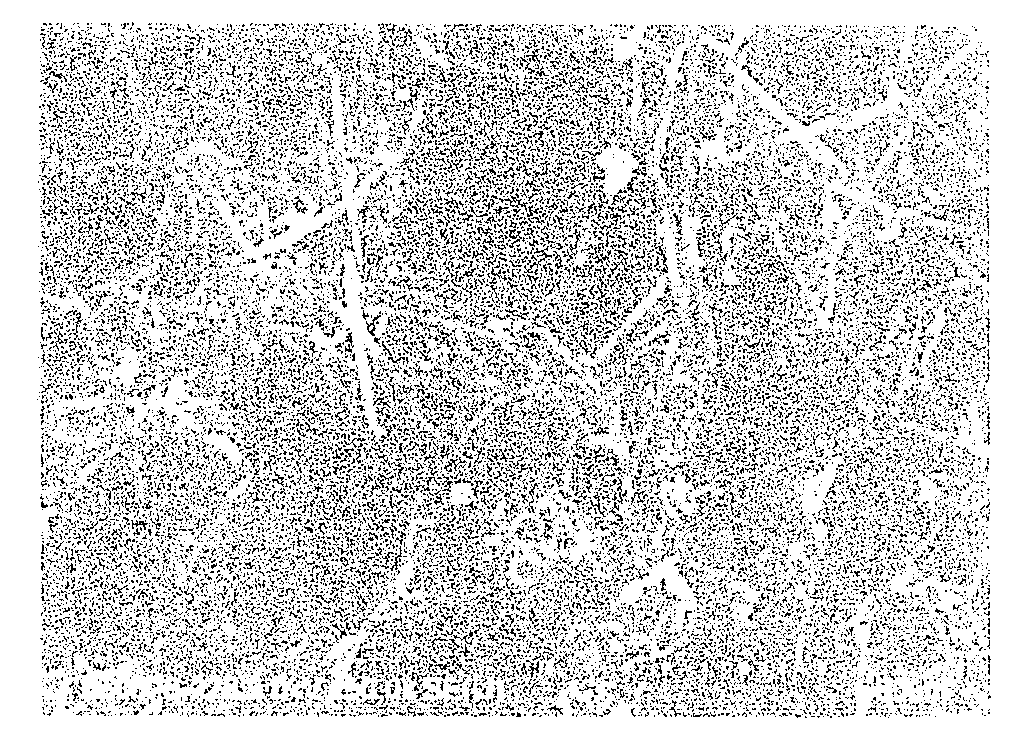

[0061]The single-walled carbon nanotubes resulting from the treatment were dispersed at a concentration of 0.05% by weight in a dimethylformamide (DMF) solvent and subjected to dispersion treatment for 30 minutes in an ultrasonic dispersion machine (Fisher Model 100 Sonic Dismembrator) to form a liquid dispersion. The resulting liquid dispersion was a carbon nanotubes dispersion with very good dispersion properties. The resulting liquid dispersion was immediately observed with an optical microscope (at a ...

example 2

Preparation of Liquid Dispersion

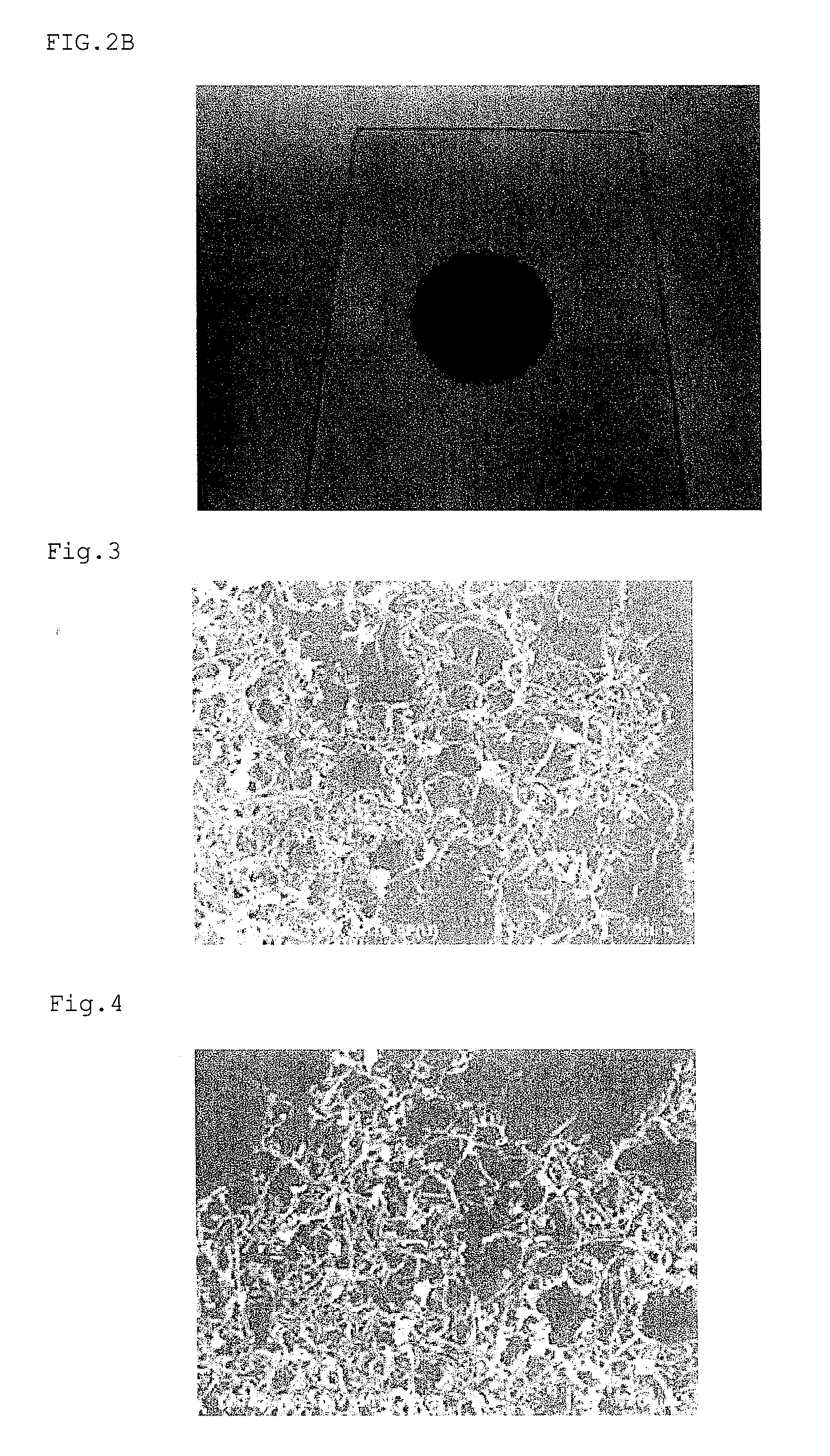

[0067]A liquid dispersion of carbon nanotubes was obtained using the process of Example 1, except that the amount of the added single-walled carbon nanotubes resulting from the UV ozone treatment was set at 0.03% by weight in the preparation of the liquid dispersion according to Example 1. The resulting liquid dispersion was immediately observed with an optical microscope, and no aggregate of carbon nanotubes was observed.

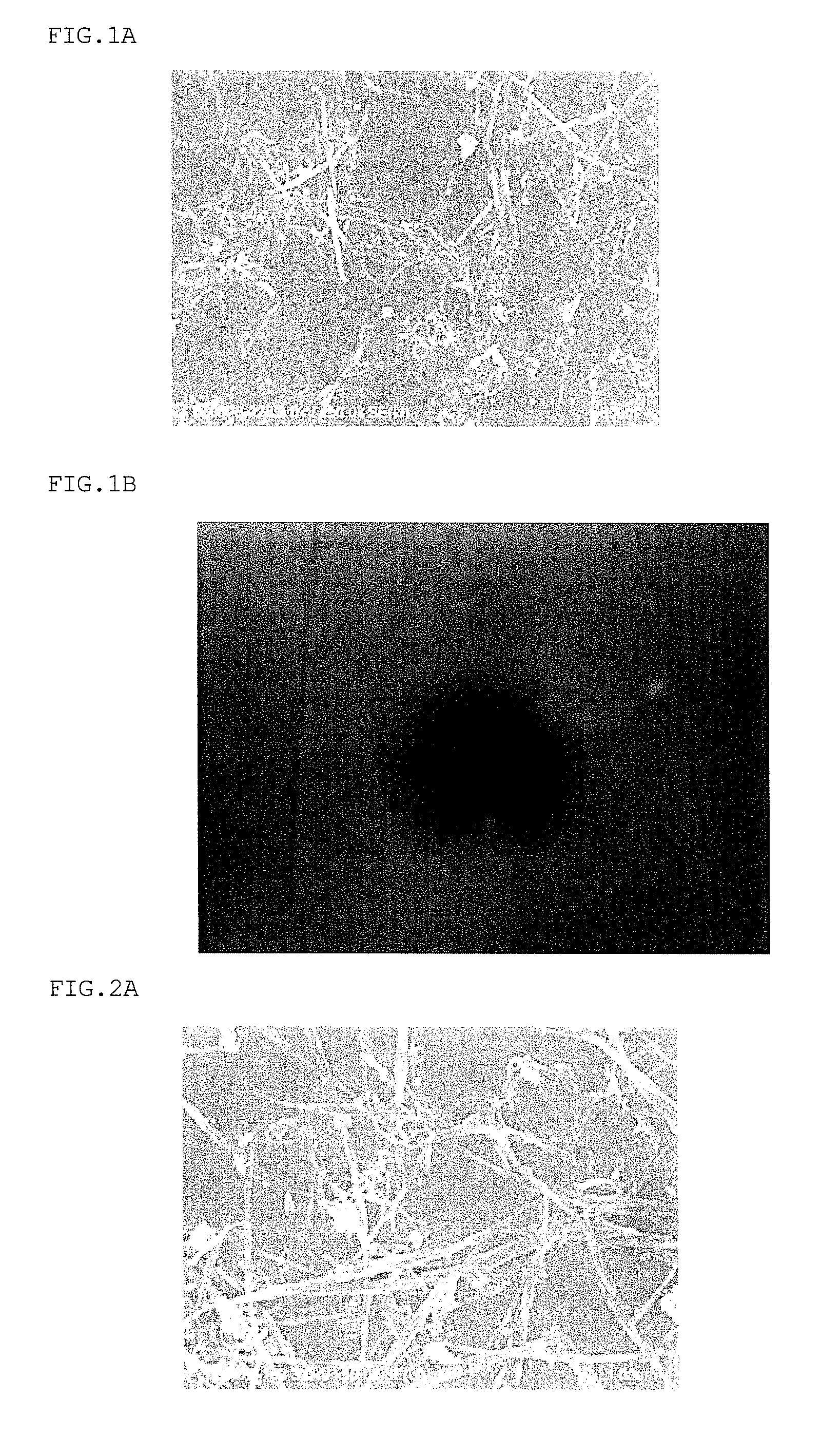

Optical Product Application

[0068]The resulting carbon nanotubes dispersion was used to form an optical product with a carbon nanotubes coating in the same manner as Example 1. The resulting product was evaluated in the same manner as Example 1 (for absorptance and surface resistivity). The results are shown in Table 1.

example 3

Preparation of Liquid Dispersion

[0069]A liquid dispersion of carbon nanotubes was obtained using the process of Example 1, except that the amount of the added single-walled carbon nanotubes resulting from the UV ozone treatment was set at 0.025% by weight in the preparation of the liquid dispersion according to Example 1. The resulting liquid dispersion was immediately observed with an optical microscope, and no aggregate of carbon nanotubes was observed.

Optical Product Application

[0070]The resulting carbon nanotubes dispersion was used to form an optical product with a carbon nanotubes coating in the same manner as Example 1. The resulting product was evaluated in the same manner as Example 1 (for absorptance and surface resistivity). The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com