Metal Laminate

a technology of metal laminates and metal sheets, applied in the direction of superimposed coating processes, liquid/solution decomposition chemical coatings, coatings, etc., can solve the problems of inability to cold reduce laminates, metals do not form satisfactory bonds to one another, and no known method of producing laminates, etc., to achieve the effect of superior corrosion resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

Method for Making a Metal Laminate

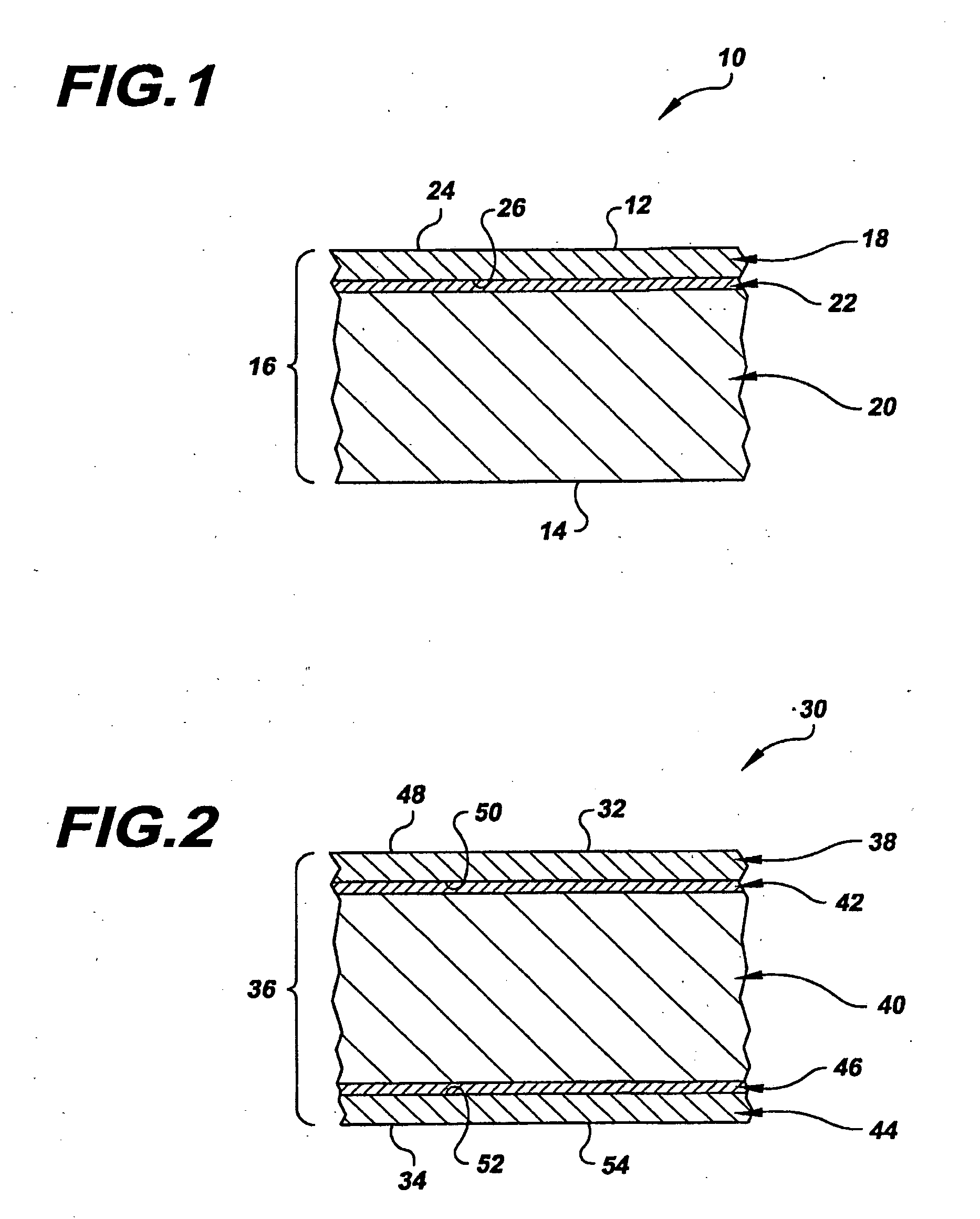

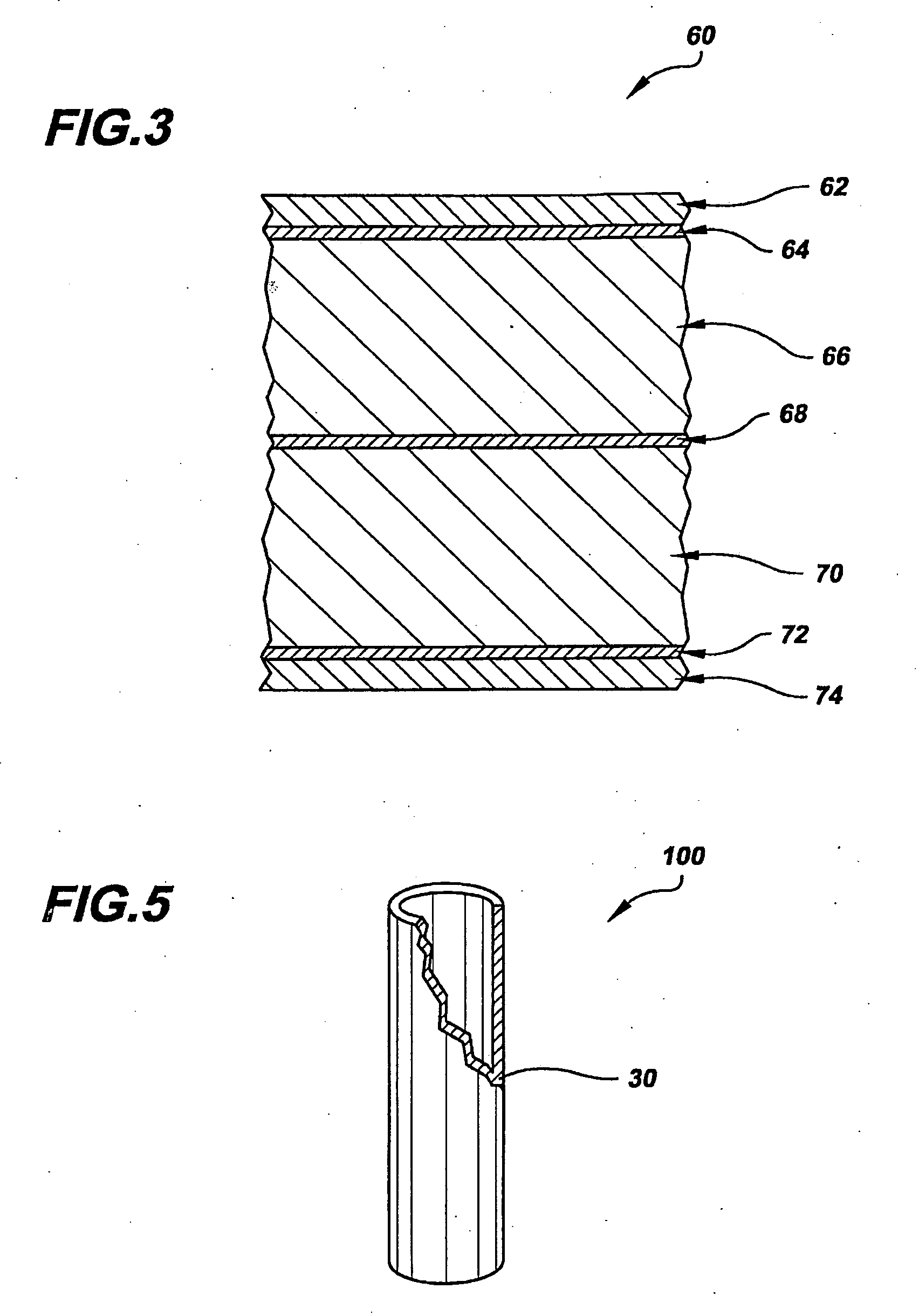

[0082]A corrosion resistant metal laminate according to the present invention was produced using a method for making a metal laminate according to the present invention as follows. First, a 625 nickel-based alloy coil (comprising about 61% nickel) 0.10 mm thick was purchased from ZAPP, USA. Next, a 409 stainless steel coil 1.5 mm thick was purchased from Thomas Steel Strip and was electroplated with 0.003 mm of nickel on both surfaces of the 409 stainless steel coil. This electroplated 409 coil was diffusion bonded by heating the stainless steel-nickel laminate in a continuous annealing line at 720° C.

[0083]Next, the diffusion bonded stainless steel-nickel laminate was placed between two 625 nickel based-alloy coils, and the five layers were roll bonded together by Engineered Material Systems forming a five layer laminate with 625 nickel-based alloy on both outer surfaces, 409 stainless steel in the middle and nickel between the stainless steel and ...

example 3

Method for Making a Metal Laminate

[0084]A metal laminate according to the present invention was produced using a method for making a metal laminate according to the present invention as follows. First, a UNS S32100 stainless steel coil 0.25 mm thick was purchased from Combined Metals of Chicago, LLC (Bellwood, Ill. US). The stainless steel coil was electroplated by Thomas Steel Strip, Corp. (Warren, Ohio US) with 0.001 mm of nickel on one side, and then the resultant stainless steel-nickel laminate was diffusion bonded by heating the stainless steel-nickel laminate in a continuous annealing line at 1,000° C.

[0085]Next, a layer of titanium stabilized low carbon steel (Severstal North American, Inc. Dearborn Mich.) 3.4 mm thick was placed between the nickel sides of two diffusion bonded stainless steel-nickel laminates as produced above, and the five layers were cold roll bonded together by Engineered Material Systems (Attleboro, Mass. US) forming a five layer laminate with stainless ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com