Structure for Preventing Peeling of Reaction Product, Process for Its Production and Process for the Production of a Semiconductor Device Using the Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]According to the structure for preventing peeling of reaction product, process for its production and process for the production of a semiconductor device using the structure of this invention, the undesired peeling of reaction product inside the chamber of a plasma etching device is conveniently preventable because of the configuration and action as described above.

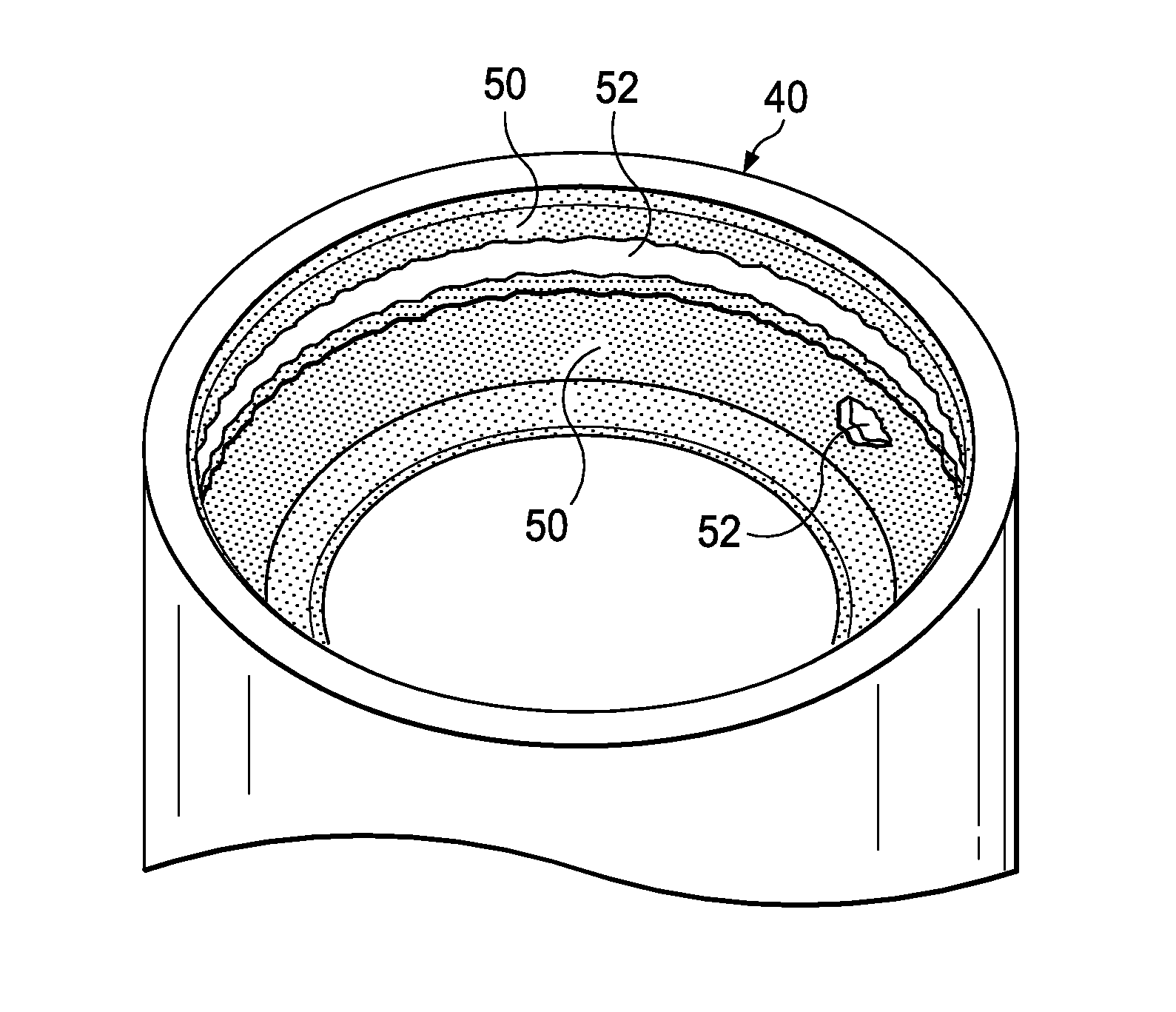

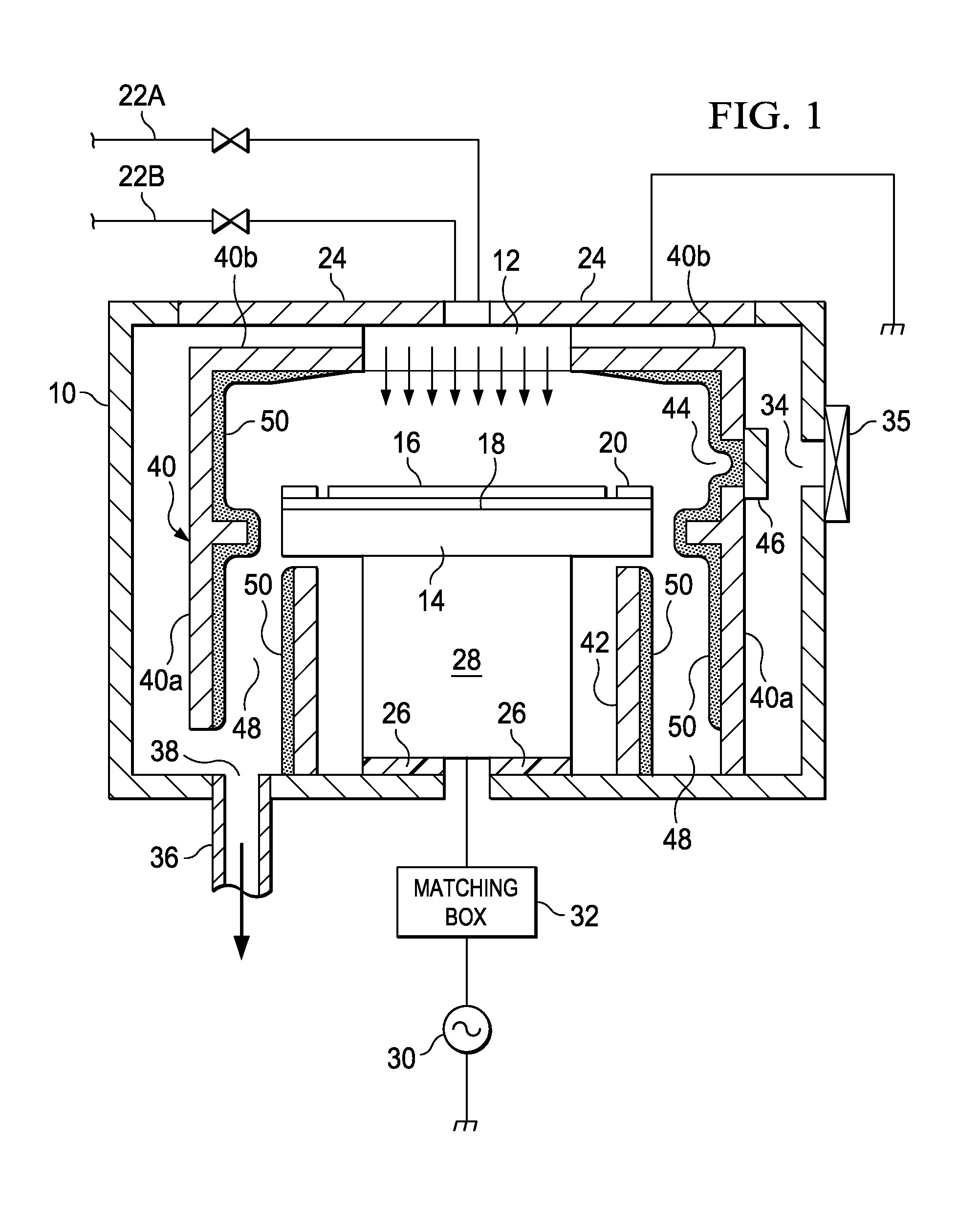

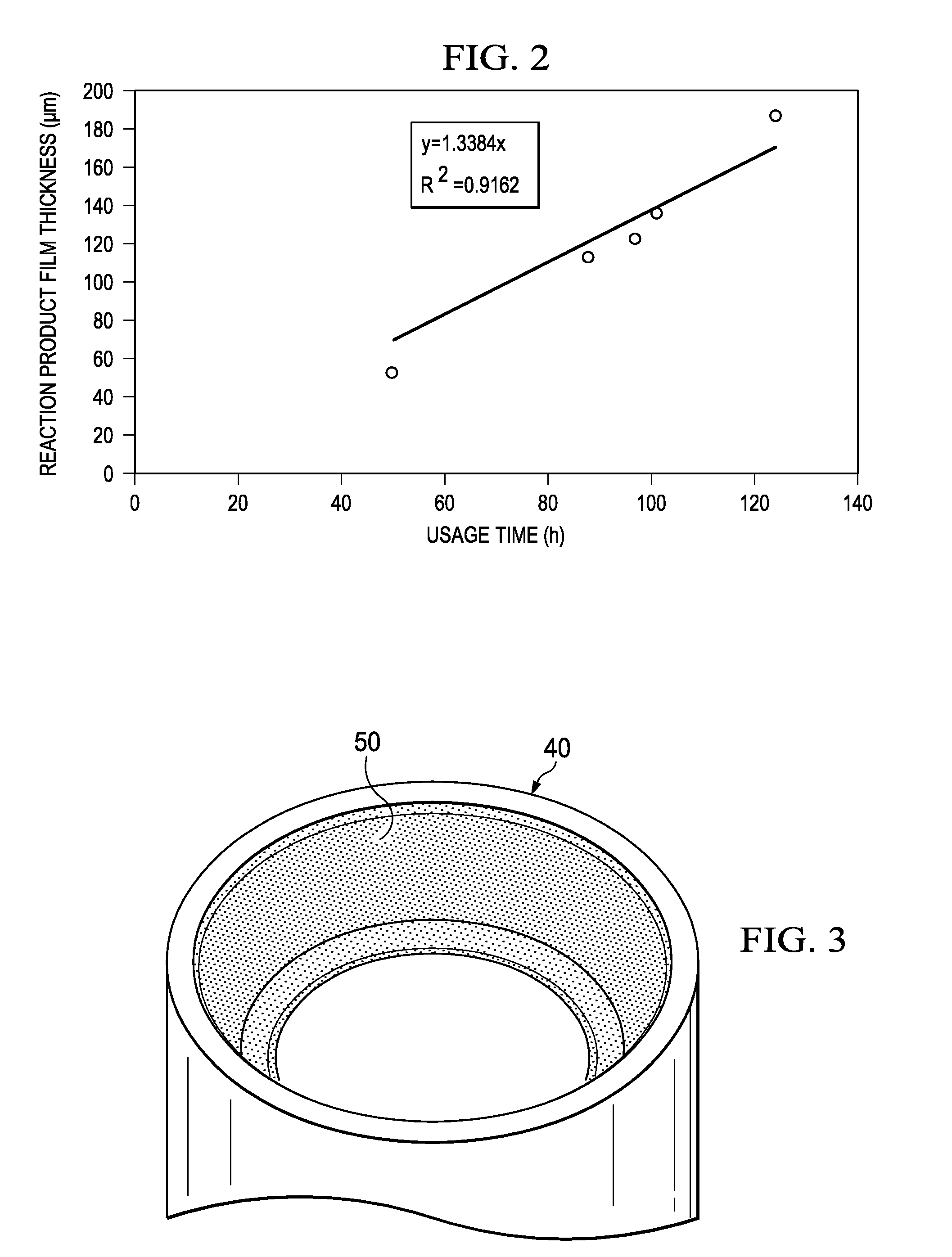

[0023]The preferred embodiment of this invention is explained with reference to the attached drawings as follows.

[0024]FIG. 1 shows a configuration of a capacitively coupled plasma etching device with one preferred embodiment of this invention applied. This plasma etching device has a chamber 10 that is a cylindrical hollow body made of aluminum (Al). An interior shower head 12 functioning also as an upper electrode and a susceptor 14 also functioning as a lower electrode are provided on the top and bottom, respectively, in parallel with the required spacing. A material to be treated, for example semiconductor wafe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Mean roughness | aaaaa | aaaaa |

| Mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com