Multi-engine system with on-board ammonia production

a multi-engine, ammonia production technology, applied in the direction of machines/engines, electrical control, separation processes, etc., can solve the problems of limiting the nox reduction capability of the system, difficult to replenish ammonia, and difficult to stor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

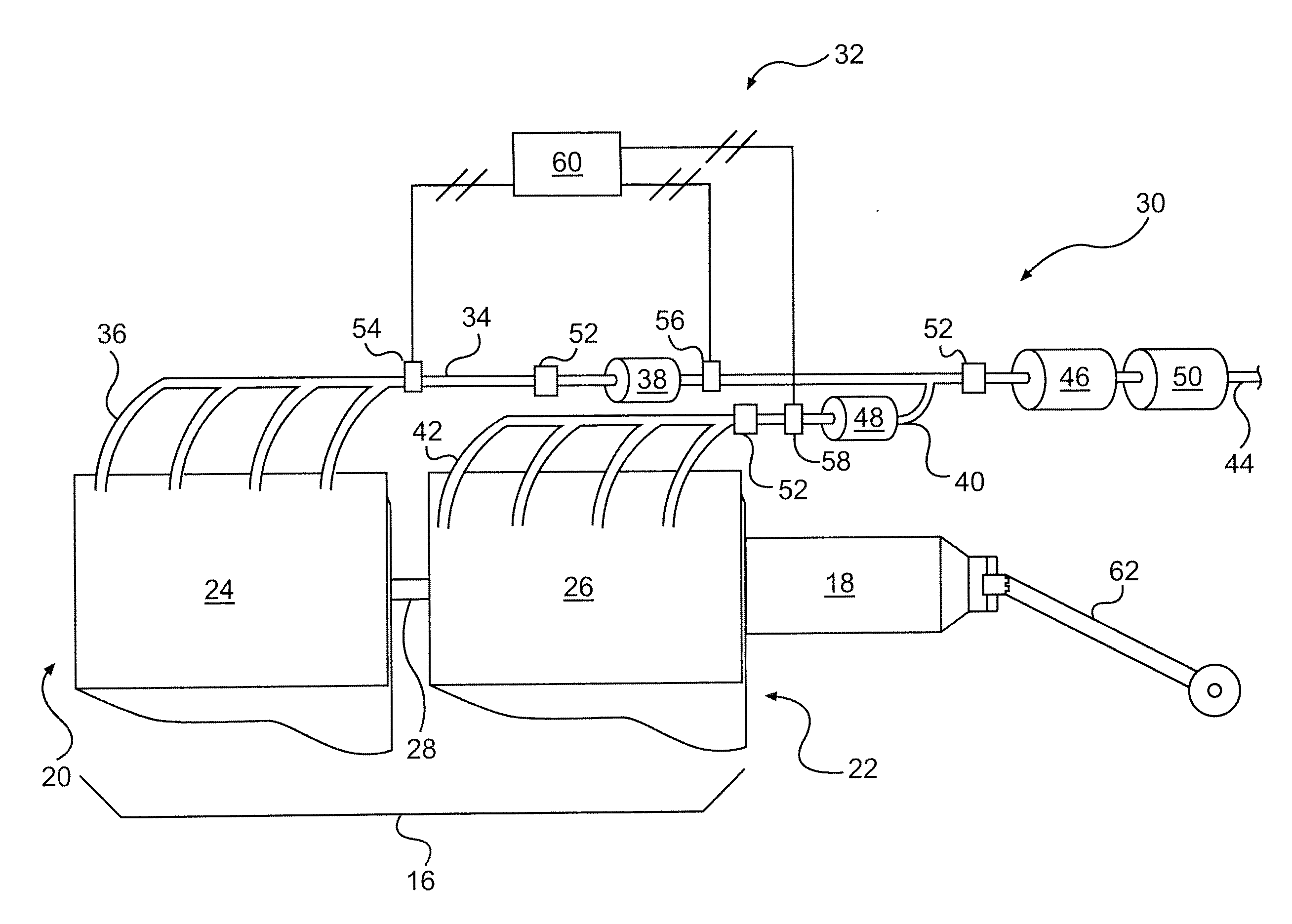

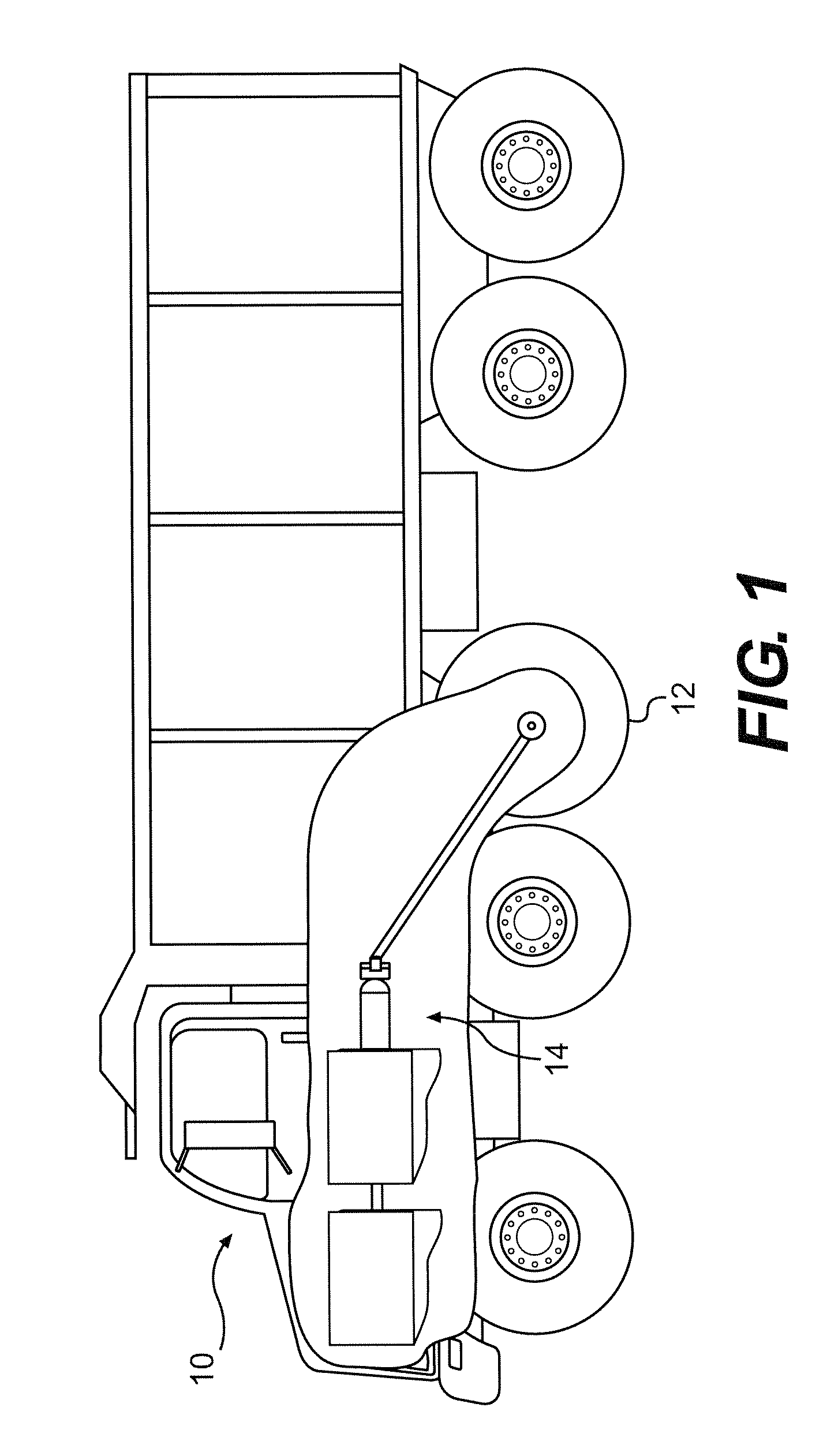

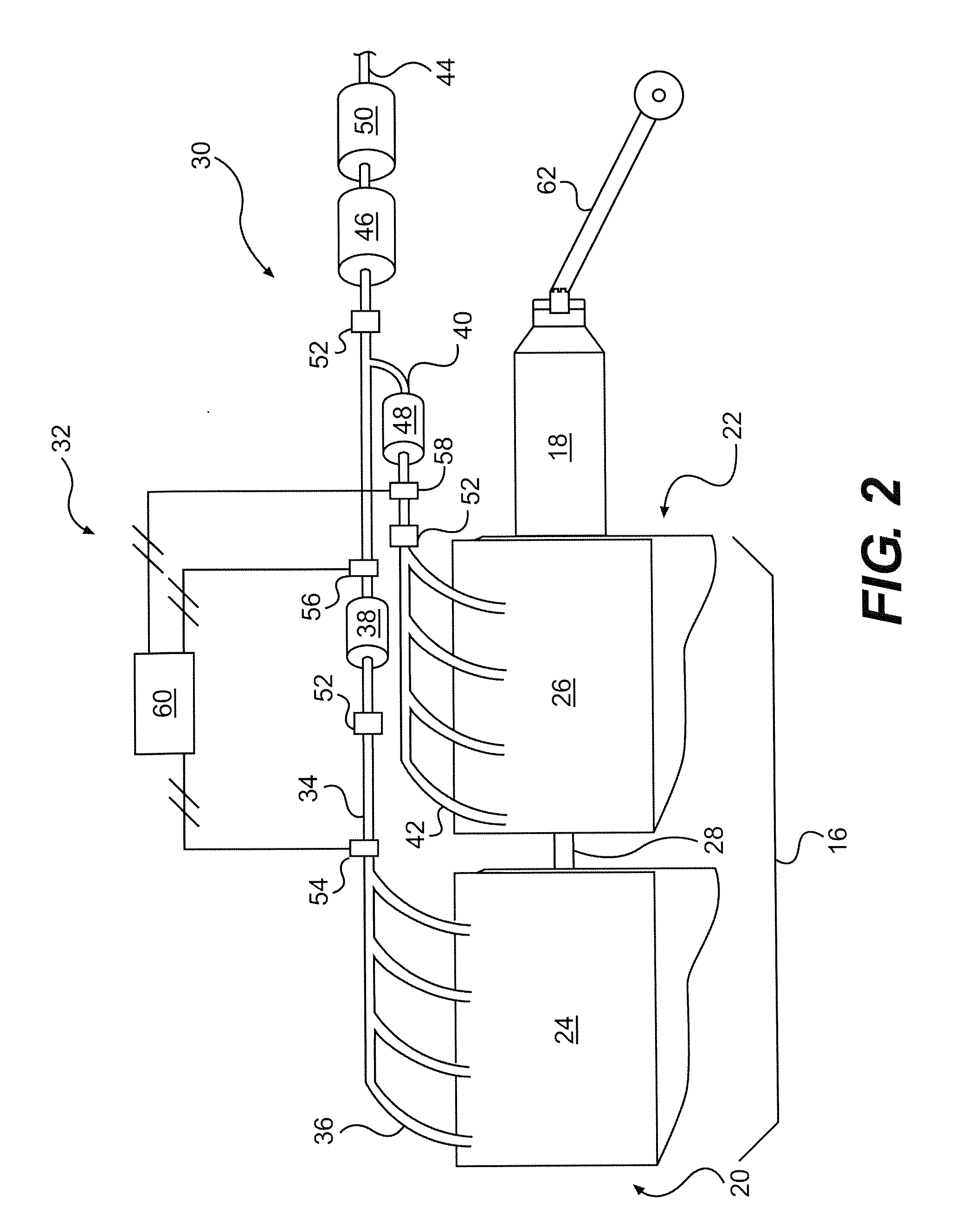

[0018]FIG. 1 illustrates an exemplary machine 10 having multiple systems and components that cooperate to accomplish a task. The tasks performed by machine 10 may be associated with a particular industry such as mining, construction, farming, transportation, power generation, or any other industry known in the art. For example, machine 10 may embody a mobile machine such as, a bus, a haul truck, a locomotive, a marine vessel, or any other type of machine known in the art. As shown in FIG. 1, machine 10 may include one or more traction devices 12 operatively connected to and driven by a power train 14.

[0019]Traction devices 12 may embody wheels located on each side of machine 10 (only one side shown). Alternatively, traction devices 12 may include tracks, belts or other known traction devices. It is contemplated that any combination of the wheels on machine 10 may be driven and / or steered.

[0020]Power train 14 may be an integral package configured to generate and transmit power to tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| electrical energy | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com