Hydrogen Generator

a generator and hydrogen technology, applied in the field of hydrogen generators, can solve the problems of increasing dependence on imported petroleum, increasing the cost of hydrocarbon fuels, so as to and reduce the risk of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

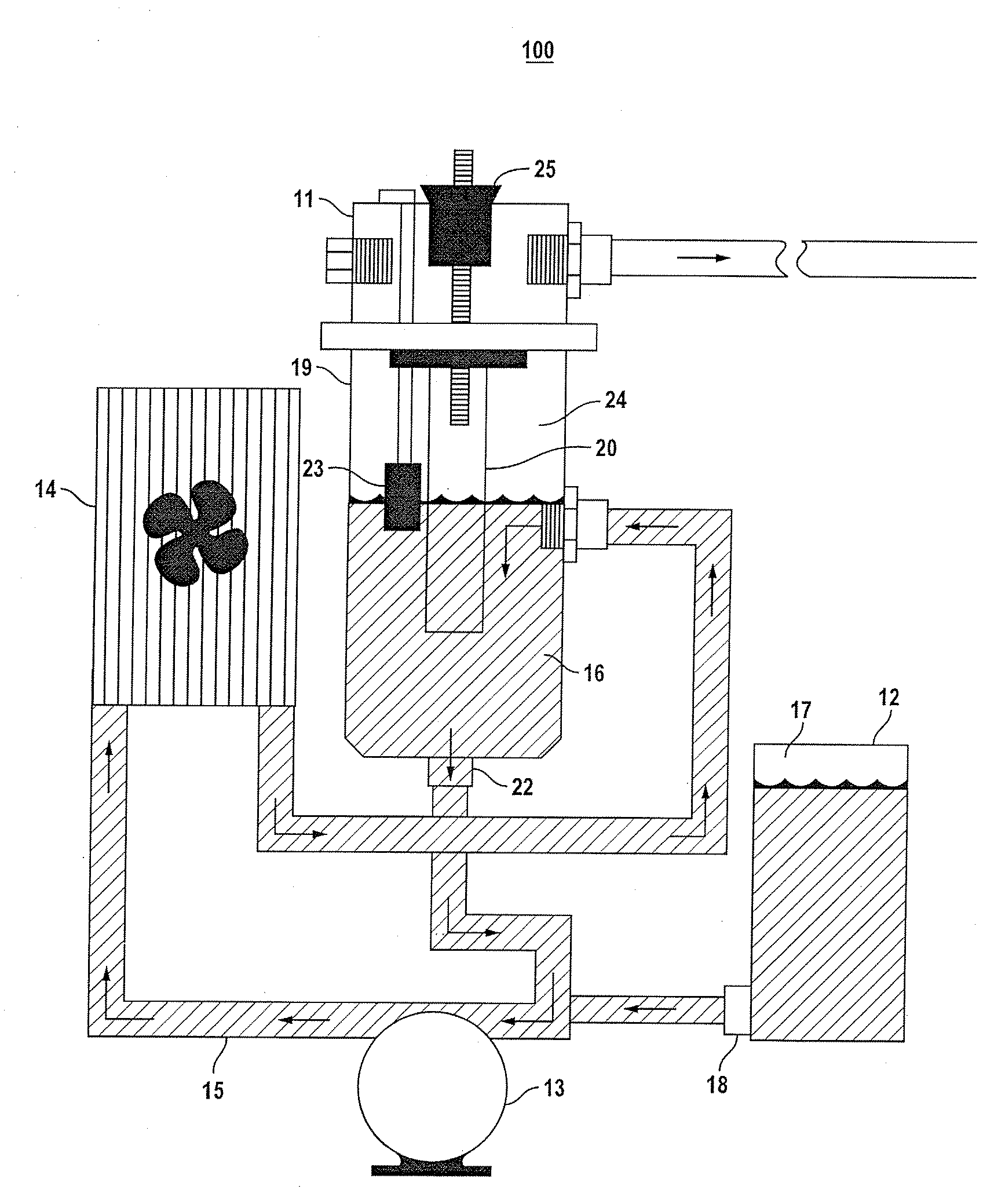

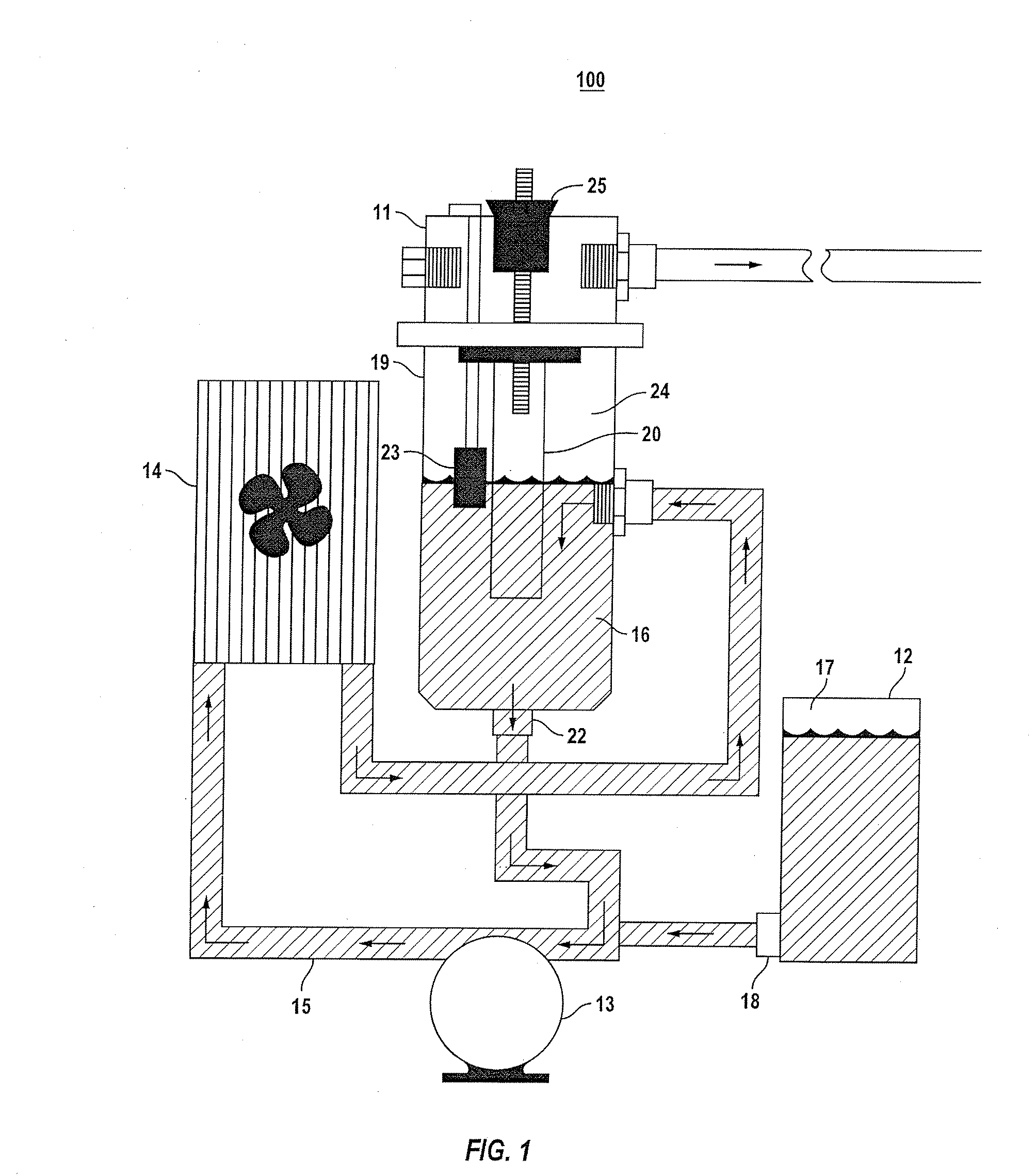

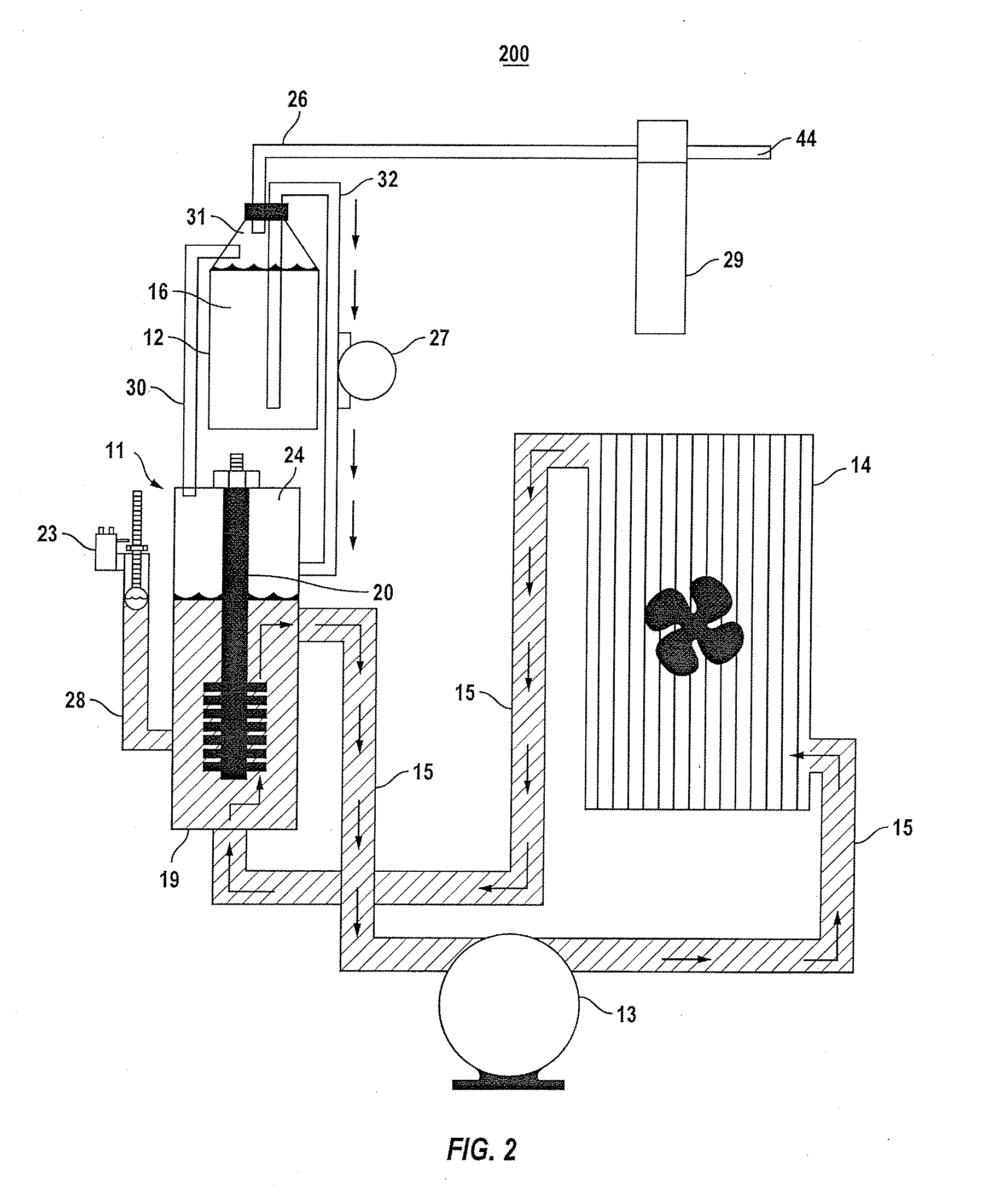

[0031]FIG. 1 illustrates a system 100 according to the present invention. In this embodiment, the system comprises an electrolytic reactor 11, a refillable reservoir 12, a pump 13, a heat exchanger 14, and conduit 15 connecting the foregoing components as shown. System 100 produces hydrogen and oxygen by electrolysis of water within reactor 11. The hydrogen and oxygen are produced to supplement hydrocarbon fuel burned in a combustion chamber, such as a wood or oil burning stove, a coal furnace, or cylinders of an internal combustion engine. Electrical power for energizing reactor 11 may originate from an independent source, or it may be derived from the electrical system of an engine. To simplify the disclosure, no combustion chambers or engines are shown in any of the figures.

[0032]Refillable reservoir 12 is configured to hold up to about two gallons of ionized water, although this volume may vary according to the particular application. Reservoir 12 may be constructed of a lightwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com