Apparatus to convey material to a pressurized vessel and method for the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

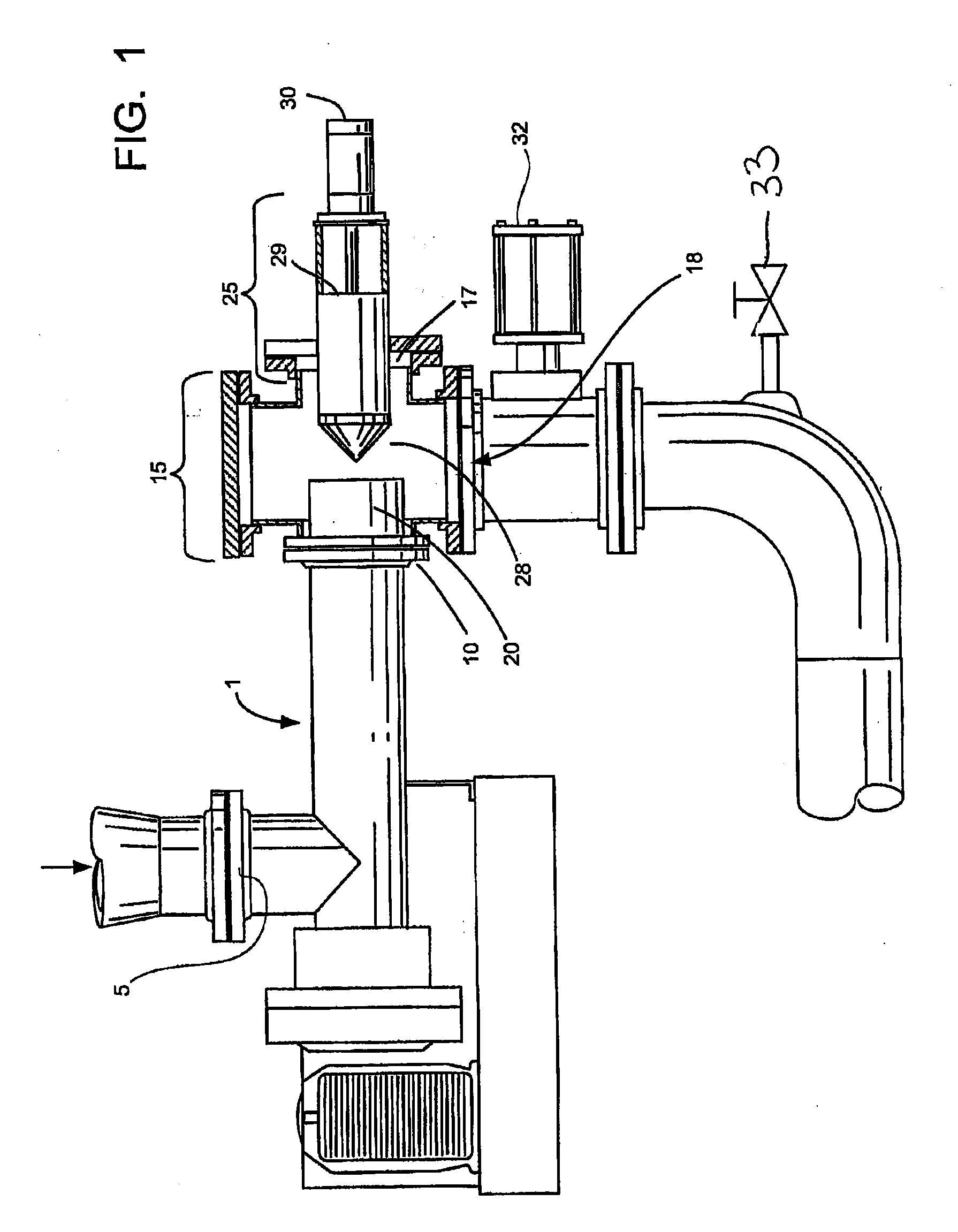

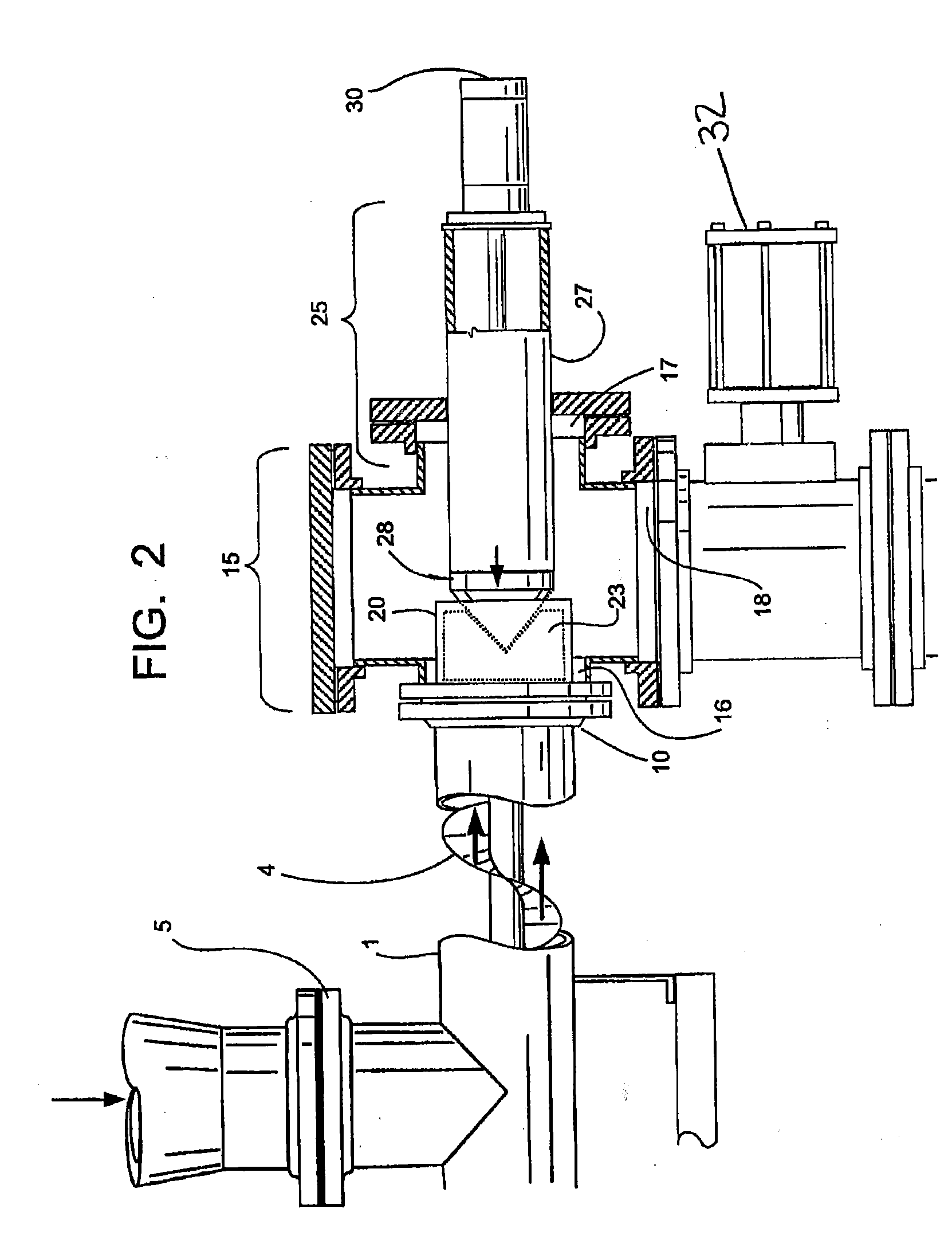

[0039]The following is an example of the apparatus of the present invention. The material retention chamber 20 has a three inch diameter, the angle of the vertex of the cone of the conical end 28 is approximately 45 degrees, the utilized motor horsepower is 10 hp, the maximum speed of the auger is 50 rpm, and the auger diameter is 3 inches. The sawdust wood rate of feed is about 100 pounds per hour and the reactor pressure is 10 psig, the sawdust has an average moisture of about 10% and grain top size of about ⅛ inch.

example 2

[0040]The following is an example of a second embodiment of apparatus of the present invention. The material is sawdust and the material retention chamber 20 has an eight inch diameter, the angle of the vertex of the cone of the conical end 28 is between 70 and 80 degrees. The auger speed is 25 rpm, producing a feed rate of about 800 pounds of sawdust per hour with a reactor pressure of about 40 psig. The useful horsepower of the motor is 15 hp. The auger size is 8 inches in diameter. When the pressurized vessel 2 is run at 30 psig, the pressure on the rear end 29 is 60 psig. It is noted that the 50% increase of horsepower utilized in example 2 represents the ratio of frictional area over the volume for the diameter (3 vs. 8 inches) of the feeders. It is observed that for materials other than sawdust (at the given % of moisture) a starting point is proposed in the application of the data above as adjusted for the coefficient of friction between the “new” material and the material of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com