Fuel cell, components and systems

a fuel cell and component technology, applied in the field of fuel cells, can solve the problems of embodied significant limitations, waste of roughly 83% of the mass, and much worse waste degr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

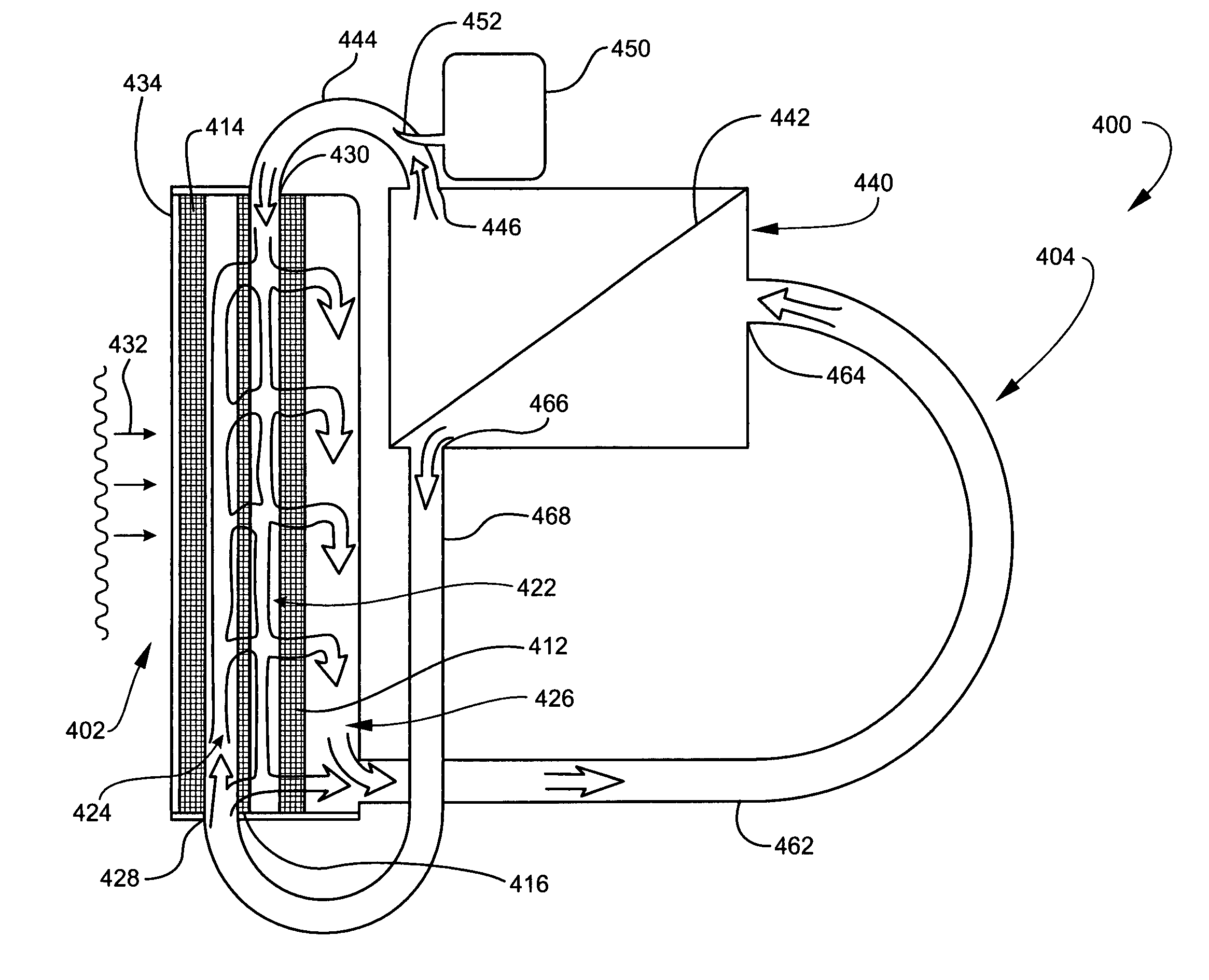

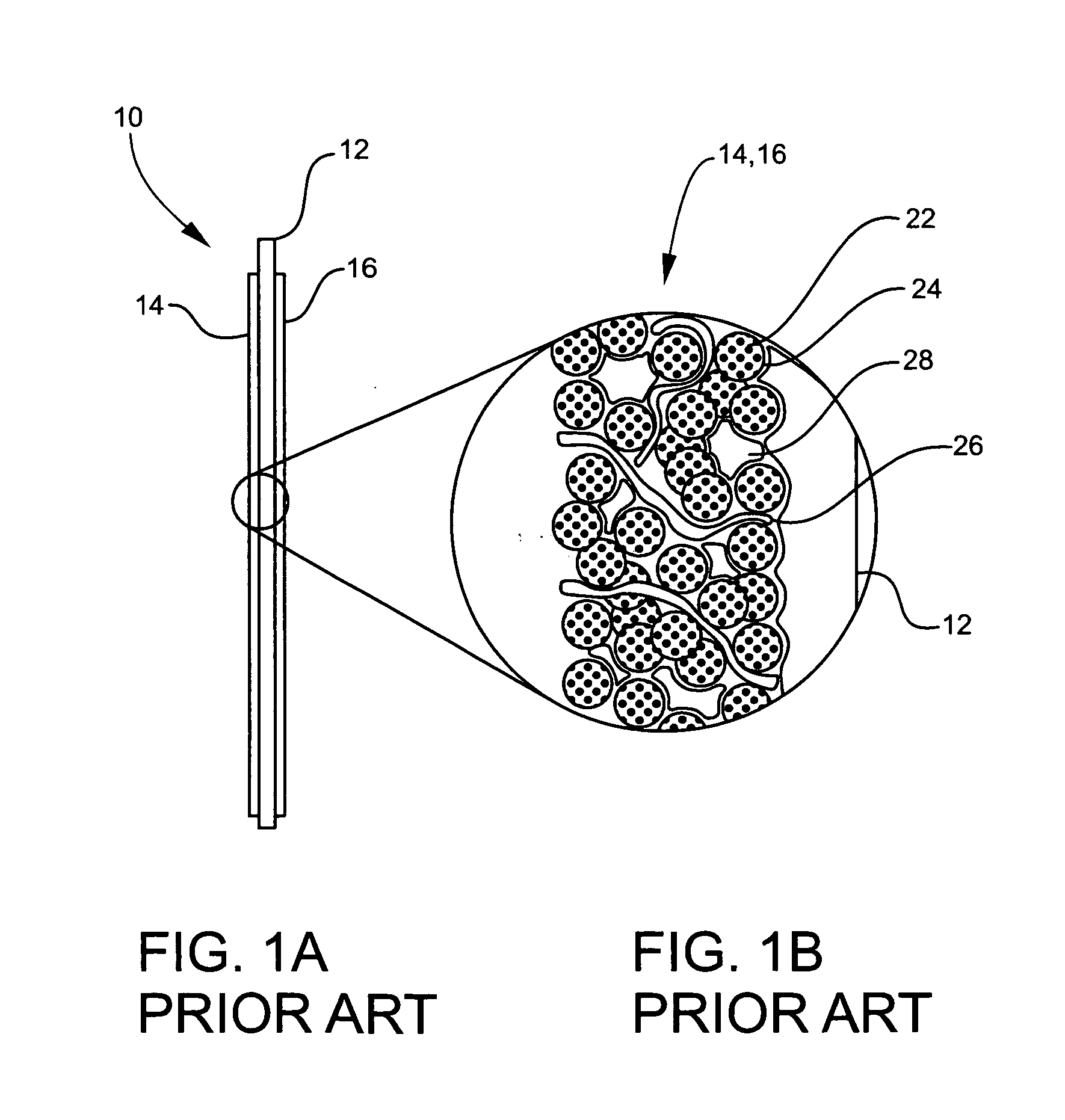

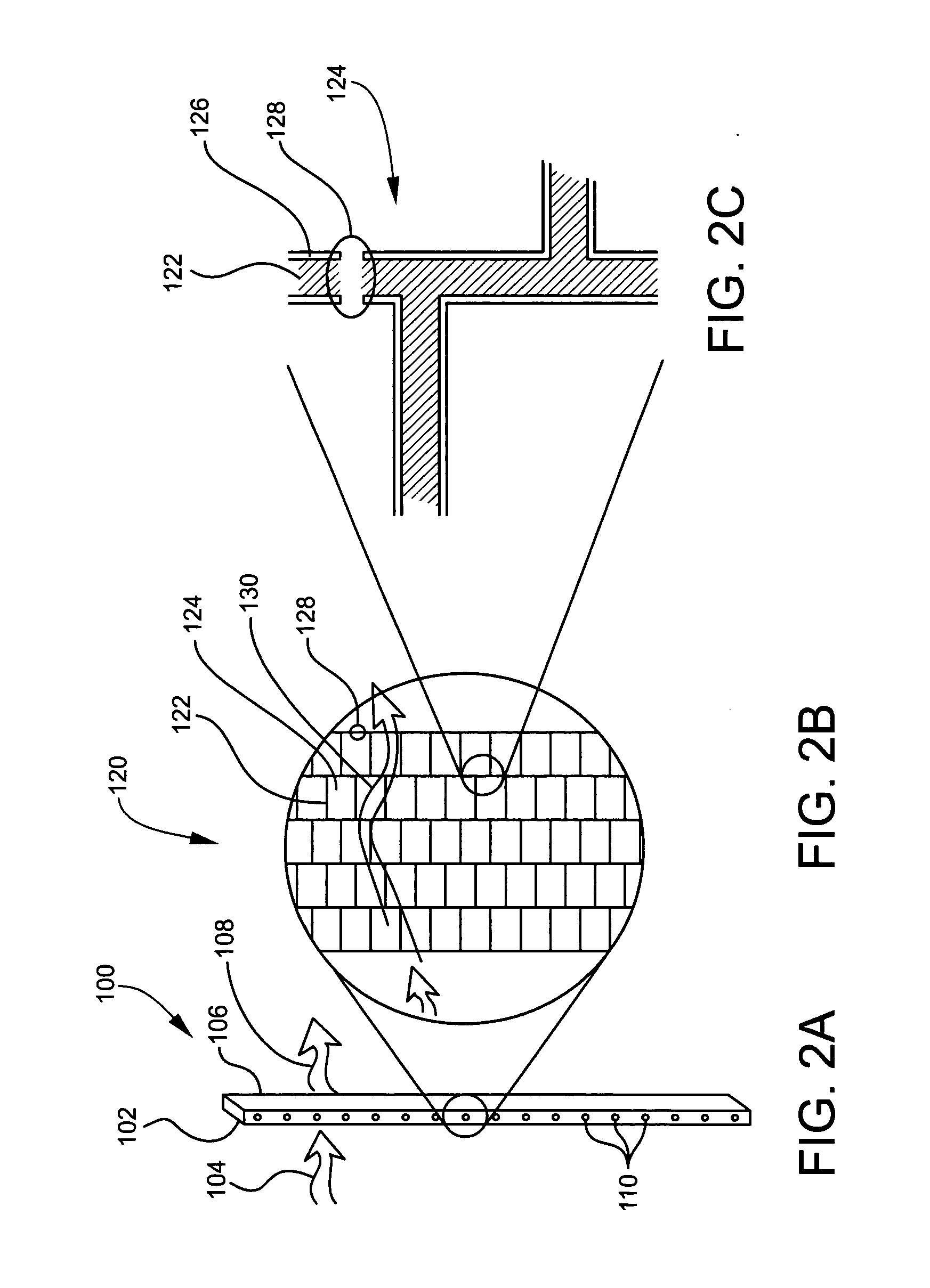

Image

Examples

Embodiment Construction

[0058]In general, the term “communicate” (e.g., a first component “communicates with” or “is in communication with” a second component) is used herein to indicate a structural, functional, mechanical, electrical, magnetic optical, fluidic, or ionic transporting, relationship between two or more components or elements. As such, the fact that one component, element, or feature is said to communicate with a second component, element, or feature is not intended to exclude the possibility that additional components may be present between, and / or operatively associated or engaged with, or otherwise interacting with, the first and second components.

[0059]As used herein, the term “fluid” generally means any flowable medium such as a liquid, gas, vapor, supercritical fluid, or combinations thereof. Moreover, the term “fluid” encompasses mixtures or combinations of liquids, vapors, gases and supercritical fluids with solid particulate matter, as in the case of particles carried in a fluid flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com