Exhaust Gas-Discharging Device of Vehicle

a technology of exhaust gas and discharge device, which is applied in the direction of machines/engines, mechanical equipment, transportation and packaging, etc., can solve the problems of reducing the output of the engine by 5% to 10%, affecting the efficiency of the engine, so as to prevent the backflow of exhaust gas and prevent the effect of back pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056]The present invention, having the above-mentioned construction and operation may be modified, as shown in FIG. 5.

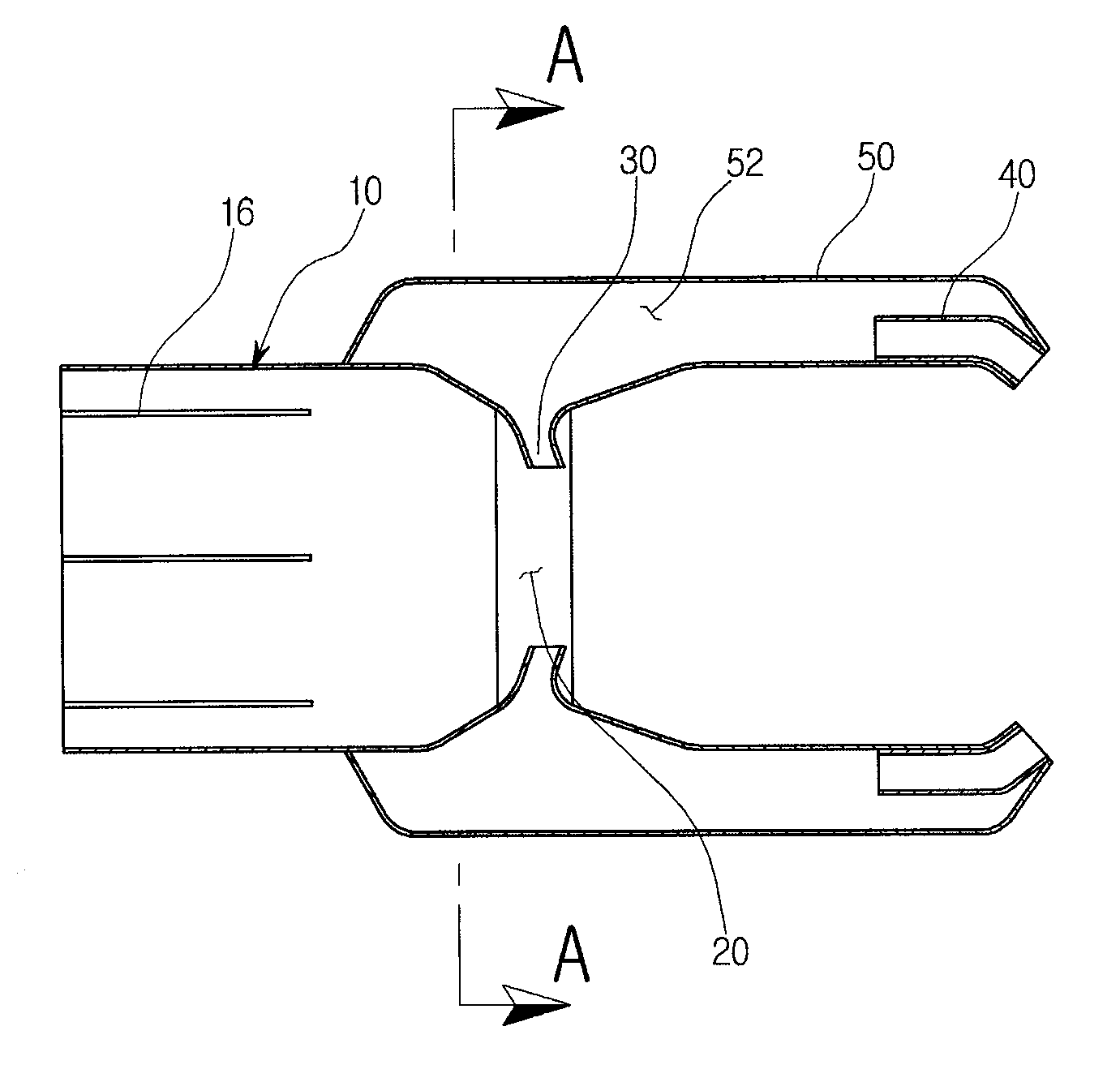

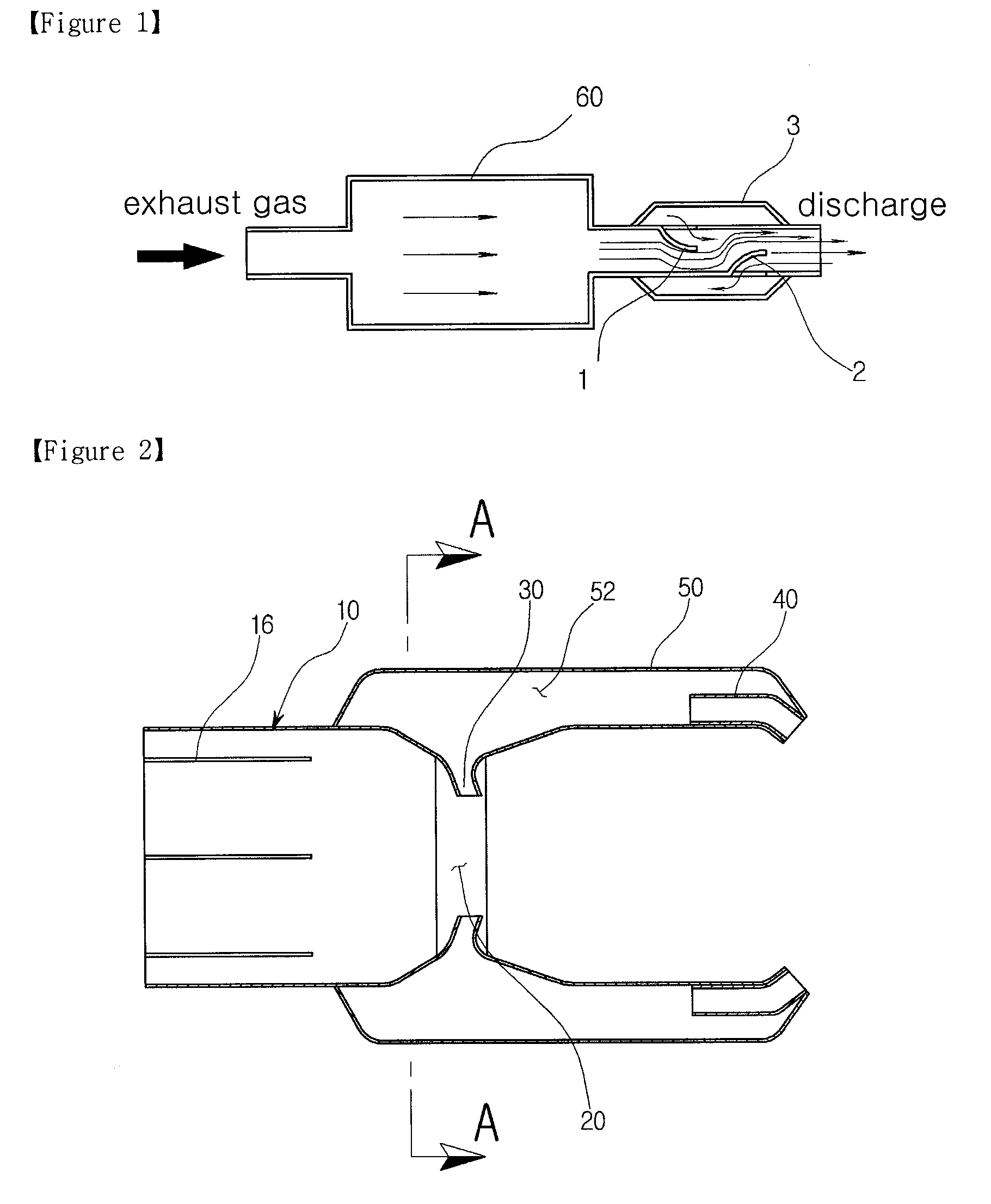

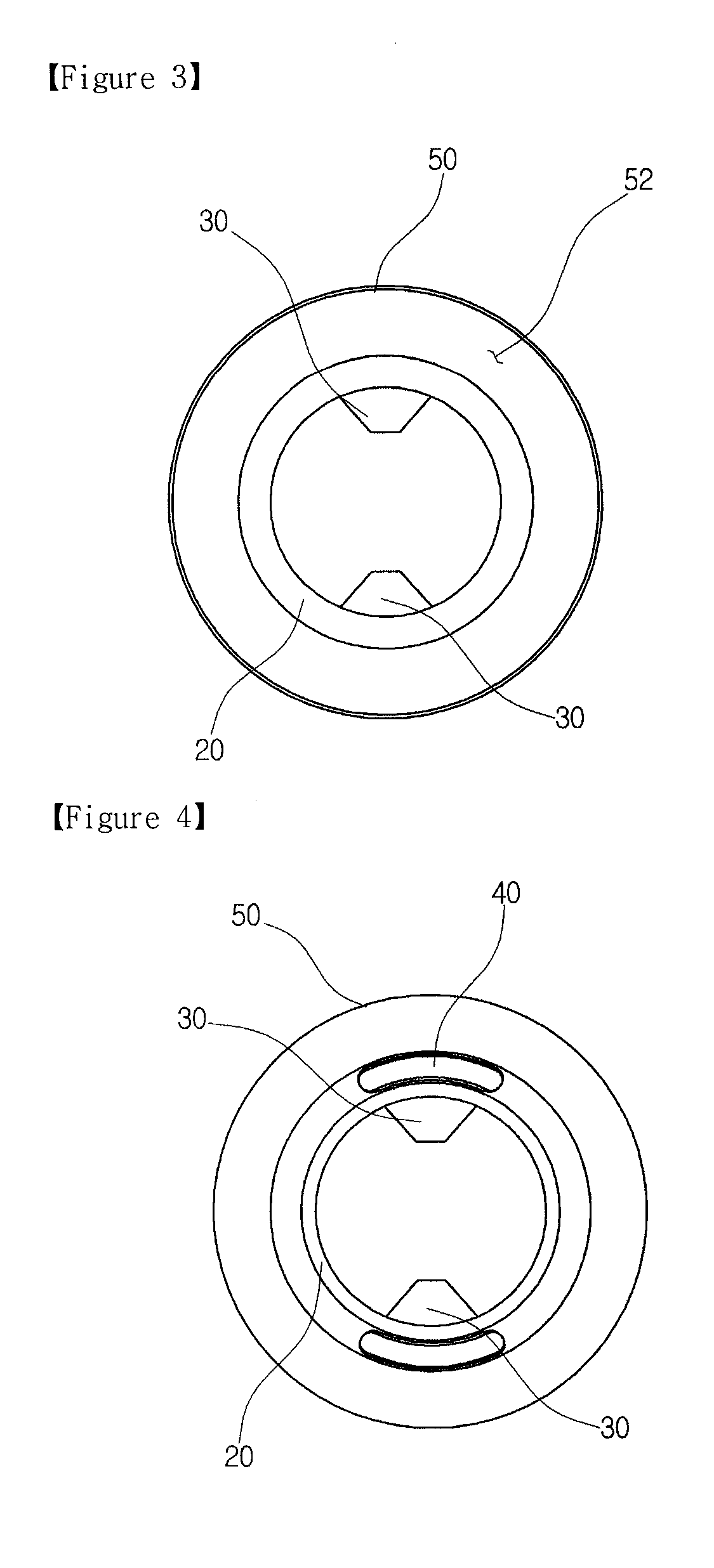

[0057]In detail, in the embodiment of FIG. 5, the air circulation operation, using a venturi passage 20 and a chamber 52, is the same as that of the prior embodiment. However, unlike the prior embodiment, the embodiment of FIG. 5 further includes a subsidiary venturi passage tube 22, which is provided in the venturi passage 20, so that outside air, which has passed through outside air discharge nozzles 30, is discharged through the subsidiary venturi passage tube 22. Thus, the discharge speed of exhaust gas, which is increased through the venturi passage 20, is further increased by the subsidiary venturi passage tube 22 (see, FIG. 8).

[0058]Each outside air discharge nozzle 30 comprises an inclined pipe, the diameter of which is reduced from the inlet end thereof, adjacent to the chamber 52, to the discharge end thereof, thus serving to increase the acceleration of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com