Waste energy conversion system

a technology of waste energy and conversion system, which is applied in the direction of waste based fuel, combustion types, lighting and heating apparatus, etc., can solve the problems of toxic emissions, and waste to energy system is not cost-effectiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

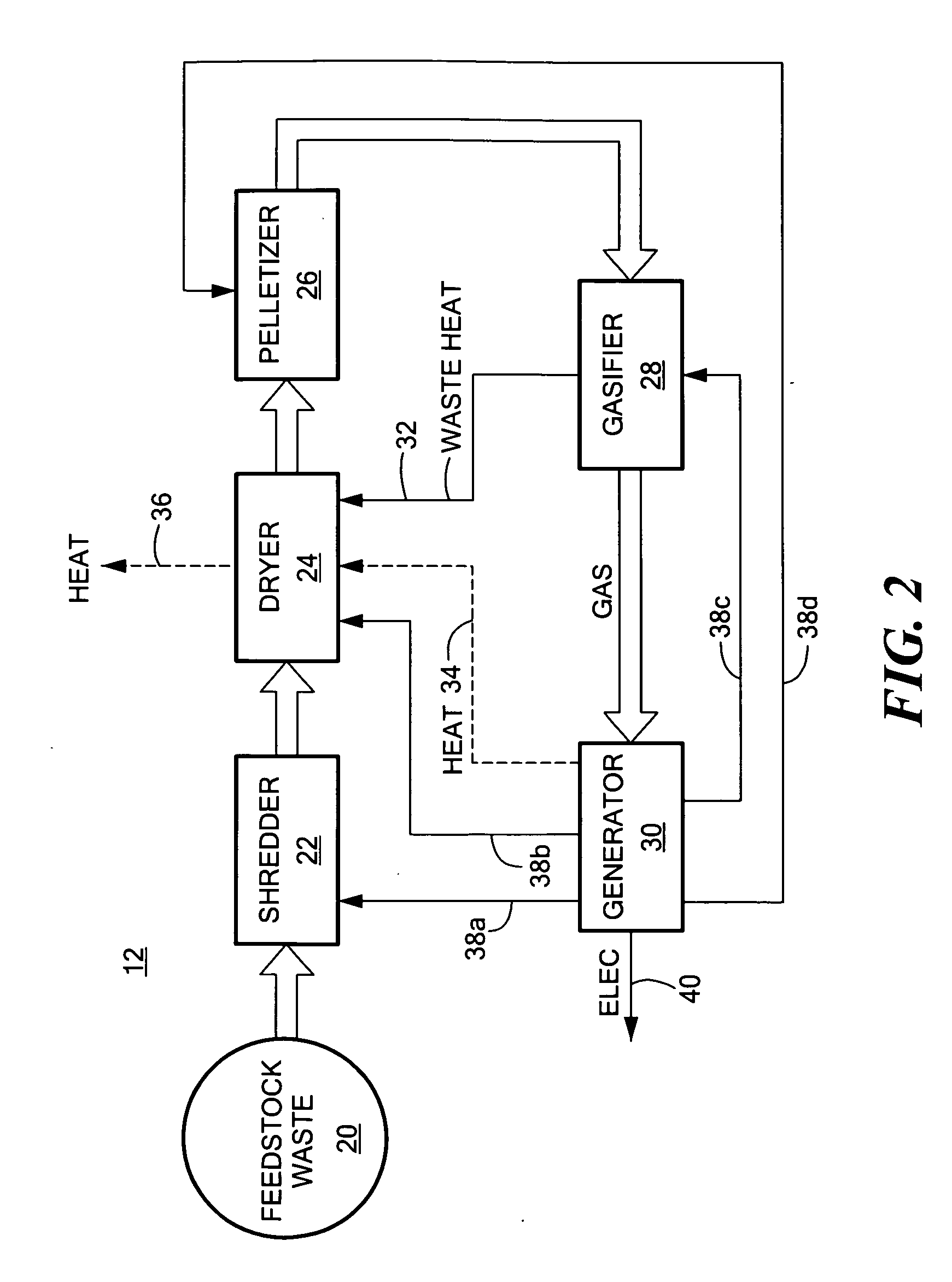

example 1

[0061]A variety of commercially-available process equipment was evaluated for use in the solid waste preprocessing unit. Experimental trials were run to assess the suitability of candidate equipment for use as-is or with modification in the preprocessing unit. A waste shredder followed by a rotary drum pellet mill was found to produce pellets of good quality and preferred size, without exceeding a parasitic energy loss target of less than 10 percent of the gross energy content of the feed waste stream. The pellets were evaluated in a small modular biopower downdraft gasifier system for their ability to make a high quality synthesis producer gas to produce heat and / or generate electricity.

[0062]Simulated waste streams, derived from Meals-Ready to Eat (MREs), were formulated according to the Force Provider Training Module (Fort Polk) with uncooked food. Table 1 shows the waste composition that was used in the solid waste pre-processing unit. Cardboard and paper were added to the MREs ...

example 2

[0065]Other shredders were evaluated, specifically those used to process hospital and plastic waste. A rotary waste shredder was used to shred stimulant encampment waste.

[0066]Shredder 22, FIGS. 3-4 incorporates hydraulic ram 50 that pushes material against a rotating cutter drum 52 that is driven by an electric motor. Material that is smaller than the screen 54 apertures fall to a collection area below, where it is pushed forward with an auger to a conveyor.

[0067]Two cases of MREs (˜12 pounds, without the magnesium heater packs) were processed for evaluation. One case was loaded into a rotary waste grinder, outfitted with a 0.5″ aperture screen, while the other case was shredded with a 1.0 inch aperture screen using the same machine. Observations were that the equipment handled the material well, and the waste was more homogenous than what was produced with the two-stage shredder. Additionally, the tool cut through thin plastic film with no difficulty, and no long stringy waste was...

example 3

[0071]An initial batch of shredded waste (100 lbs) was processed for pelletization using a roller press. FIG. 7 is a schematic view of a roller press 76 that was used in the test program. Material 60 from feed hopper 62 is supplied into the roll nip with a horizontal screw 64 driven by a variable speed drive 66. Material to be processed is placed into the feed hopper 62 from where it flows into the screw at the feed inlet. The material is then compacted between two rolls 64a and 64b which are cantilevered on the end of shafts outside bearing blocks 68. The rolls are also driven by a variable speed drive. A fully adjustable hydraulic system 70 provides the force holding the rolls together.

[0072]The exit stream from the roll press is a moderately densified sheet of waste. The final densification operation involves passage through briquetting rolls to form the solid waste-based fuel product. The waste will leave these stages having the desired dimensions and density.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com