Cellulose ester film and process for producing the same

a technology of cellulose ester and cellulose ester, which is applied in the direction of transportation and packaging, other domestic articles, coatings, etc., can solve the problems of deformation failure, sticking failure, deformation failure, etc., and achieve excellent optical characteristics, excellent productivity, and excellent productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0207]In manufacture of a cellulose triacetate film, firstly, fine particle dispersion liquid was produced as follows by the method of the present invention.

(Production of Fine Particle Dispersion Liquid)

[0208]

Ethanol27 parts by weightSilicon dioxide fine particles 3 parts by weight(Trade name: Aerosil 200V,Primary particle size: 12 nm;produced by Japan Aerosil Co., Ltd.)

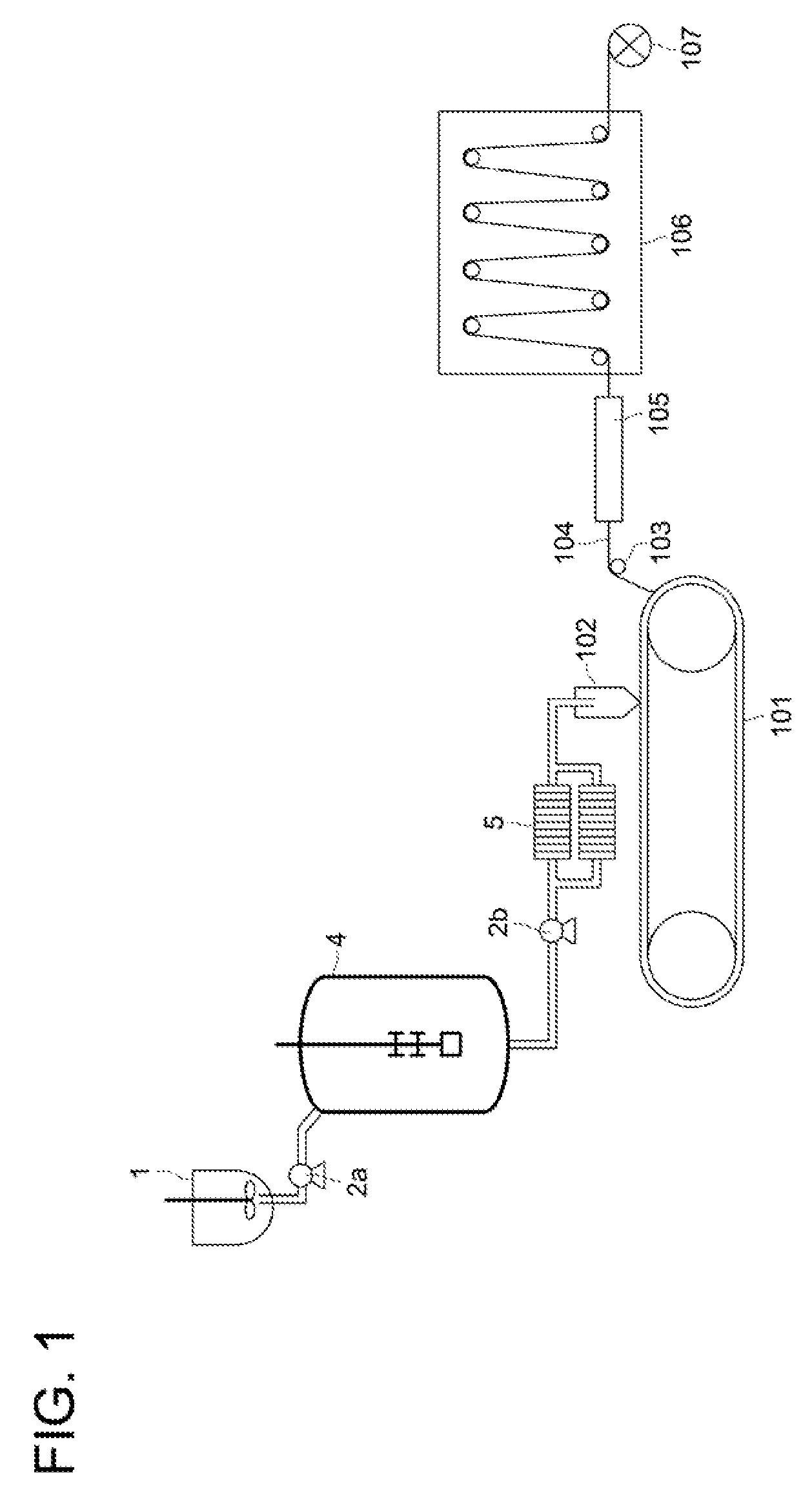

[0209]The above-mentioned ingredients were put into a container and are mixed, and the mixture was stirred at a rotation speed of 500 rpm for 30 minutes, after that, the resultant mixture was dispersed with a pressure of 24.5 MPa by a Manthon Gaulin type hyperbaric pressure dispersion machine (fine particle dispersion liquid preparing tank) 1 (refer to FIG. 1), whereby the dispersion liquid was produced.

(Dope Composition)

[0210]

Cellulose triacetate (acetylation degree: 61.0%)100 parts by weightEthylphthalyl ethyl glycolate (plasticizer A) 2 parts by weightTriphenyl phosphate (plasticizer B) 8 parts by weightMethylene...

example 2

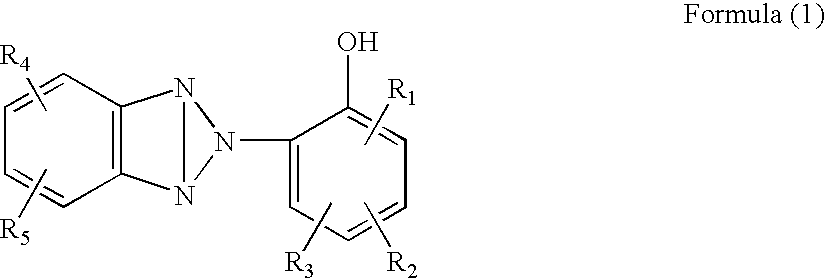

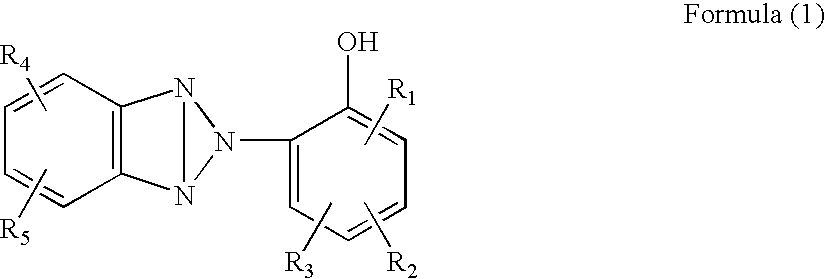

[0219]With the same way as that in the case of the above Example 1, cellulose triacetate film was produced by the method of the present invention. Into the fine particle dispersion liquid in Example 1, the same resin as the cellulose triacetate film was dissolved and mixed, and further, a liquefied ultraviolet absorber was dissolved and mixed, whereby the additive liquid was produced.

(Production of Additive Liquid)

[0220]

Fine particle dispersion liquid 22 parts by weightCellulose triacetate 12 parts by weight2-(2′-hydroxy-3′,5′-di-t-butylphenyl) benzotriazol 26 parts by weight(ultraviolet absorber)Methylene chloride290 parts by weight

(Dope Composition)

[0221]

Cellulose triacetate (acetylation degree: 61.0%)100 parts by weightEthylphthalyl ethyl glycolate (plasticizer A) 2 parts by weightTriphenyl phosphate (plasticizer B) 8 parts by weightMethylene chloride475 parts by weightEthanol 50 parts by weight

[0222]The materials of the above-mentioned dope compositions were put into a dissolvin...

examples 3 to 12

[0227]With the same way as that in the case of the above Example 2, cellulose triacetate film was produced. Except that the kind of the used fine particles, the additive amount (% by weight) of the fine particles to the cellulose triacetate, the adding timing of the fine particle dispersion liquid, the dissolving and mixing time period (minute) after the adding of the fine particle dispersion liquid, the dissolving and mixing temperature (° C.) at the time of adding the fine particle dispersion liquid, and the method of adding the ultraviolet absorber addition liquid (UV liquid) were changed as shown in Table 1, the cellulose triacetate films with a film thickness of 40 μm were produced as the same way as that in Example 2.

[0228]With regard to samples of the cellulose triacetate film produced in these Examples 3 to 12, the kind of the used fine particles, the additive amount (% by weight) of the fine particles to the cellulose triacetate, the adding timing of the fine particle dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com