Method of detoxification treatment for filter with persistent substance adhering thereto

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

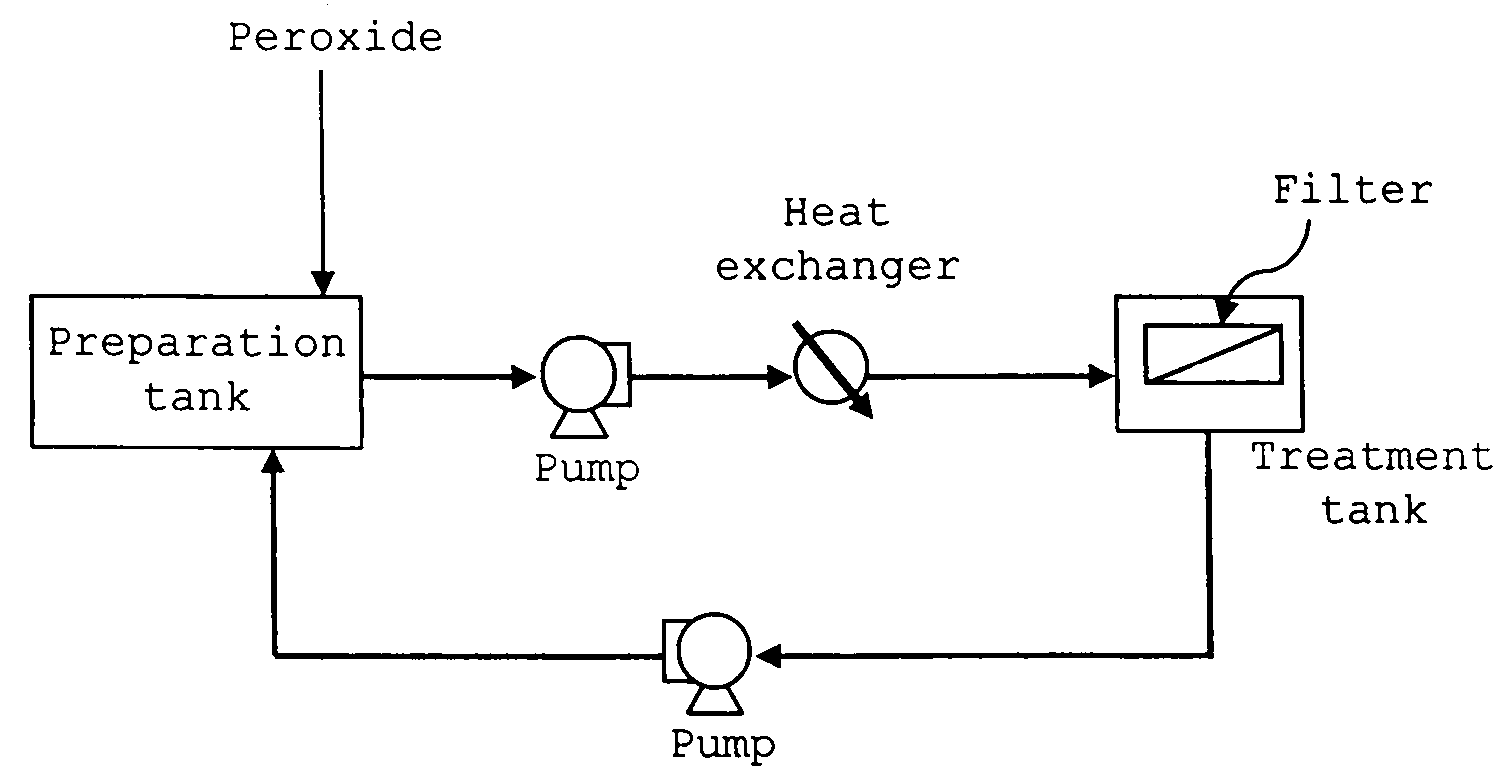

FIG. 1

[0104]A microfiltration membrane (MF membrane) with dioxins adhering thereto was detoxified using the treatment apparatus shown in FIG. 1.

[0105]A hot water bath (volume: 1 L) (heat exchanger) heated to 95° C. was provided between a preparation tank (volume: 2 L) and a treatment tank (volume: 0.5 L). The preparation tank was connected to the treatment tank, through a hot water bath, with a Teflon (registered trademark) tube with a diameter of 0.5 cm. The lower part of the treatment tank was also connected to the preparation tank with a Teflon (registered trademark) tube. A tube pump was provided between the preparation tank and the hot water bath, and between the treatment tank and the preparation tank to allow a downwardly flowing stream to be generated in the treatment tank, as well as to allow the liquid to circulate.

[0106]A microfiltration membrane (MF membrane) with a diameter of 11 cm and a pore size of 0.45 μm contaminated with dioxins (dioxin concentration: 6500 pg-TEQ / ...

example 2

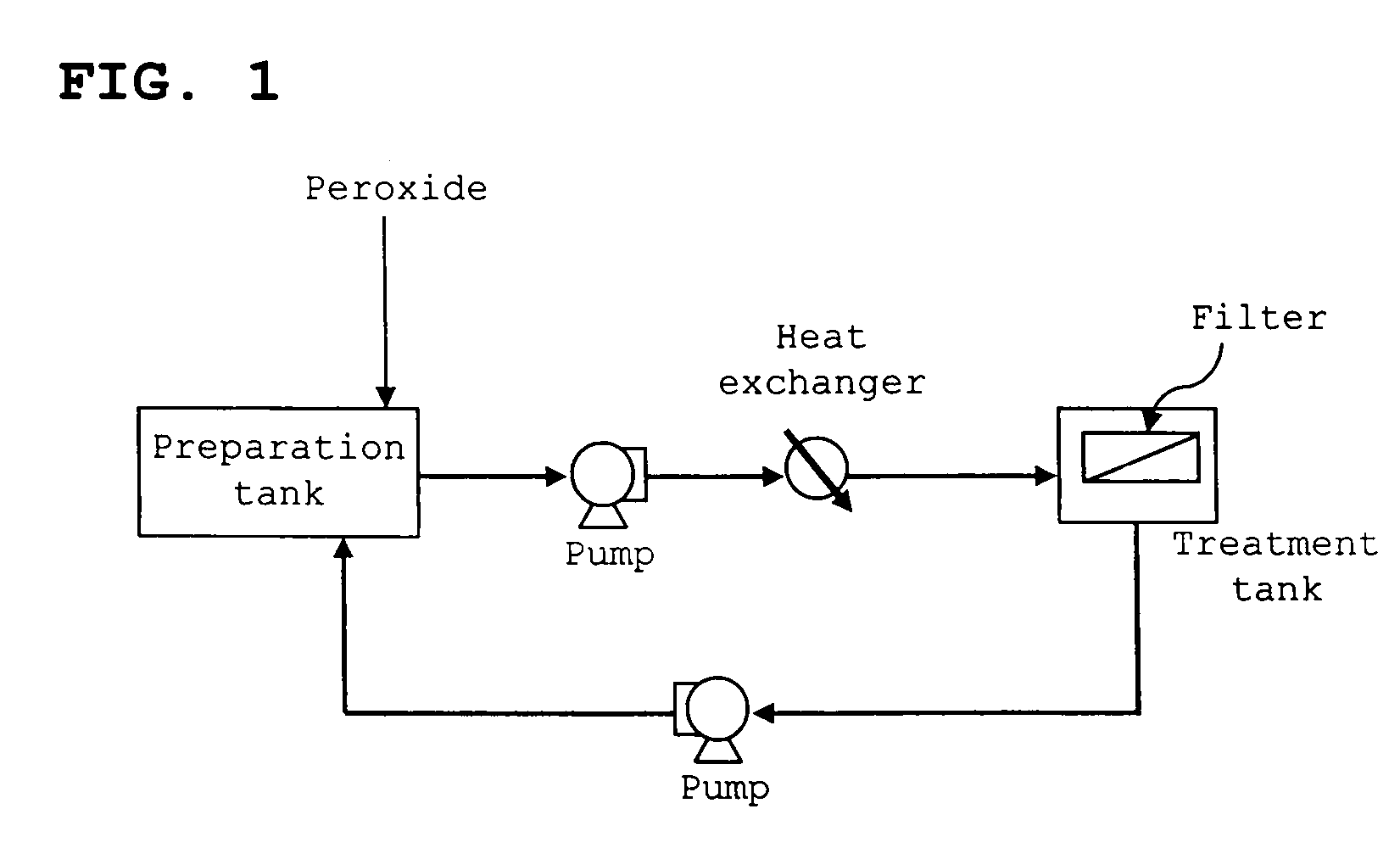

[0108]Using the treatment apparatus shown in FIG. 2-1, a pleated type filter with dioxins adhering thereto was detoxified.

[0109]A heat exchanger and a pump were provided between a preparation tank (10 L) and a filter contaminated with dioxins (dioxin concentration: 10000 pg-TEQ / g, pleated type, pore diameter: 2 μm, membrane area: 0.15 m2). A switchover valve was provided between the ejection port of the pump and the filter, whereby line A (a line which is normally used) running from the inlet of the filter to the outlet of the filter, and line B running from the outlet of the filter to the inlet of the filter were provided. As a result, the flow direction of the aqueous persulfate solution (chemicals) could be changed reversibly.

[0110]Sodium persulfate was successively added to the preparation tank every 24 hours in such a manner that the concentration of sodium persulfate became 3% within 2 hours. The liquid temperature was kept at 80° C., and the flow direction of the aqueous sodi...

example 3

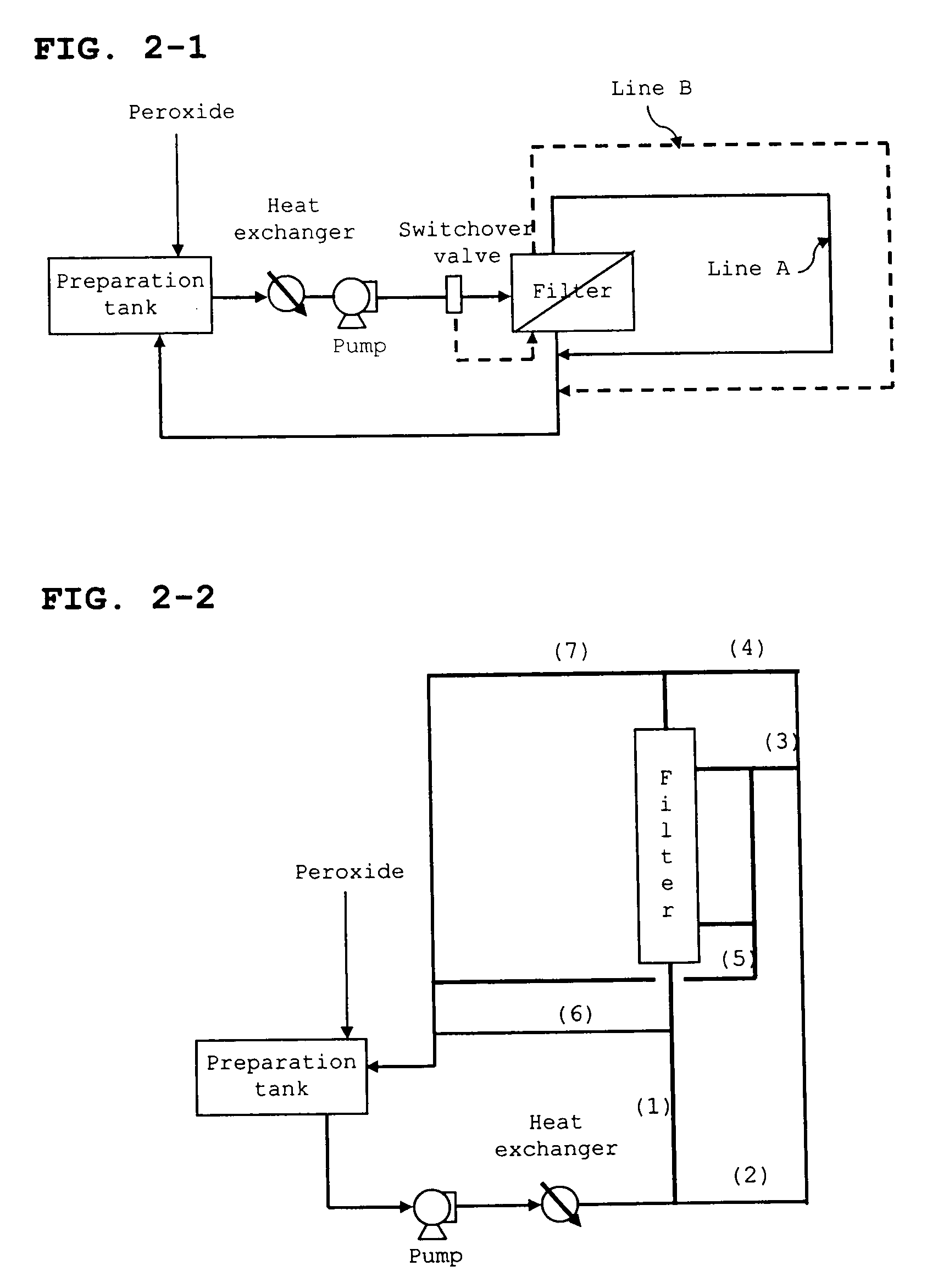

[0112]Using the treatment apparatus shown in FIG. 2-2, a hollow fiber type filter with dioxins adhering thereto was detoxified.

[0113]A heat exchanger and a pump were provided between a preparation tank (100 L) and a filter contaminated with dioxins (dioxin concentration: 8000 pg-TEQ / g, hollow fiber type, cartridge Φ 16.5 cm, length 106.6 cm). Lines (1) to (7) were provided around the filter, and a valve was provided at a branch of each line. Combination of opening and closure of the valves was as follows.

1. The valves of lines (1), (5) and (7) are open with the valves of lines (2), (3), (4) and (6) being closed

2. The valves of lines (2), (4), (5) and (6) are open with the valves of lines (1), (3) and (7) being closed

3. The valves of lines (2), (3), (6) and (7) are open with the valves of lines (1), (4) and (5) being closed

[0114]The flow channel and liquid flow in 1 above are shown in FIG. 4-1, the flow channel and liquid flow in 2 above are shown in FIG. 4-2, and the flow channel an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com