Door Frame Compartment of Cast Titanium and Structural Fuselage Part

a technology of cast titanium and structural fuselage, which is applied in the direction of fuselages, sustainable transportation, transportation and packaging, etc., can solve the problems of high production and assembly costs of such cfp components, high production and assembly costs, and high cost of corresponding conventional aluminum components, etc., and achieves low production costs, low weight, and easy repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

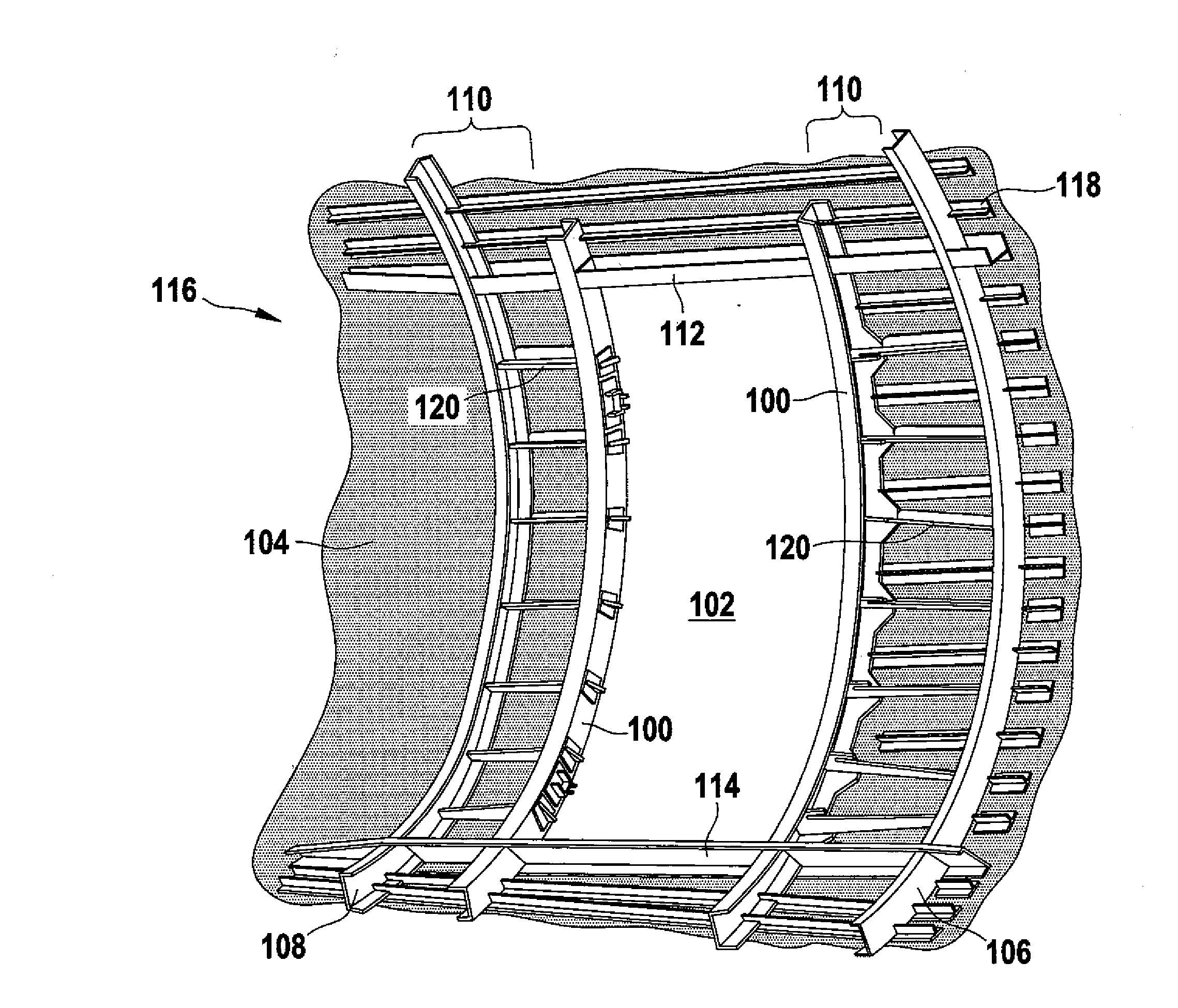

first embodiment

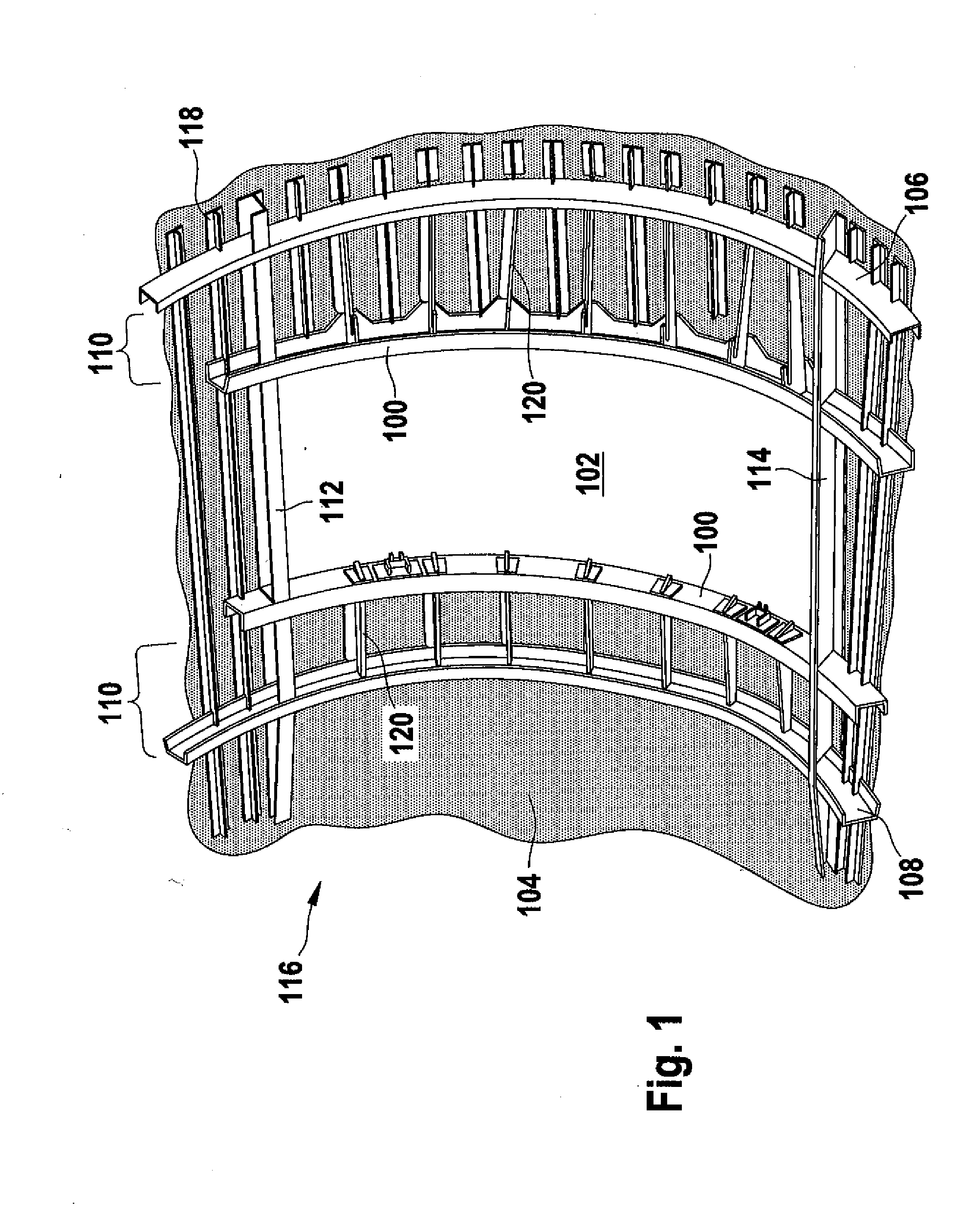

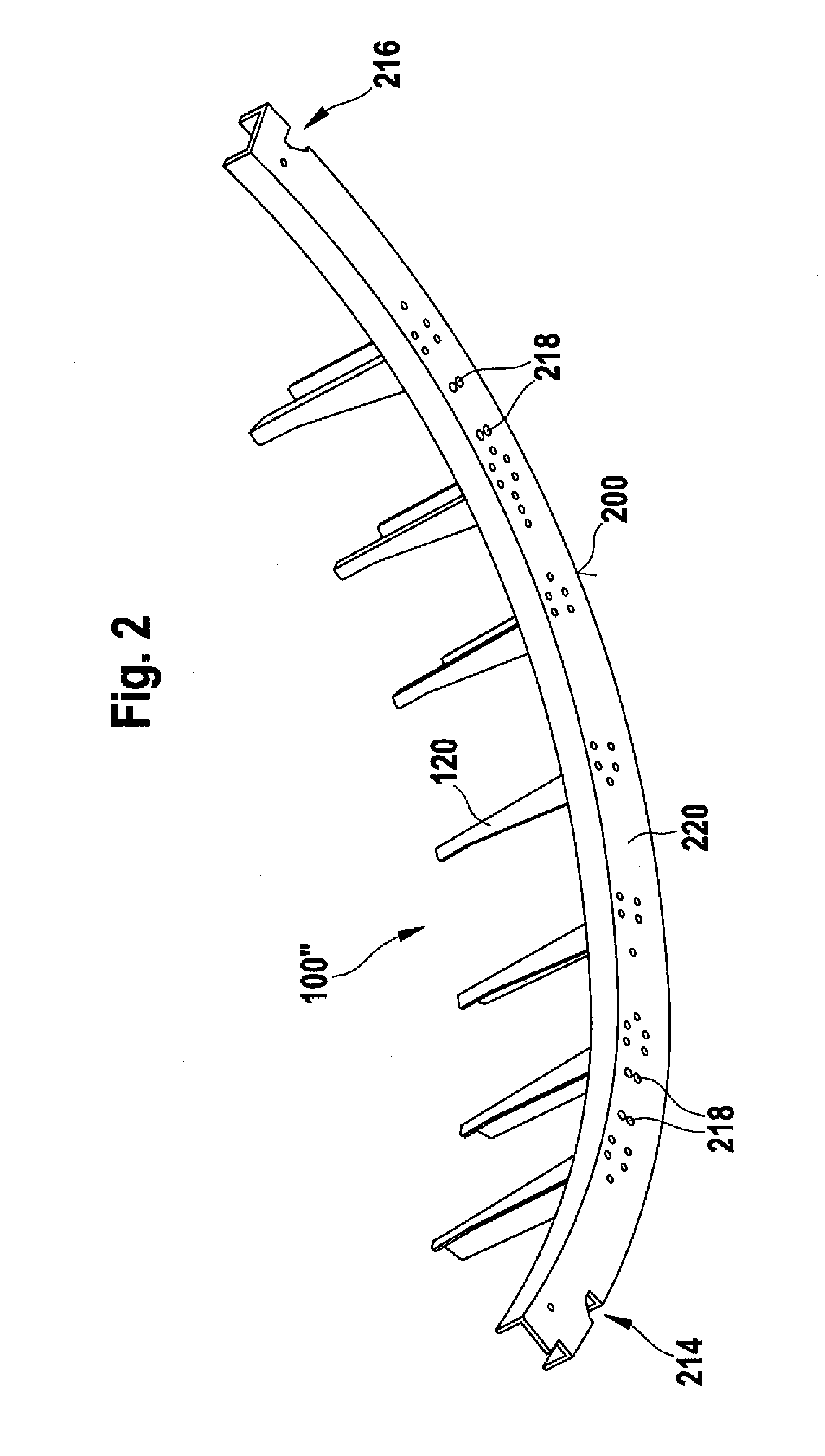

[0038]FIG. 4 shows a perspective view of a door frame rib 100 of cast titanium, which represents a door frame component 100 according to this invention. The door frame rib 100′, shown in FIG. 2, may be used as part of a fuselage structure such as that shown in FIG. 1, just as door frame rib 100′ shown in FIG. 2. Webs 212, which, unlike the conventional door frame rib, are constructed as formations of a single casting 100, are arranged inside the profile of door frame rib 100, also C-shaped. Accordingly, no overlapping surface regions or rivets are required for fastening. A locking unit 202 is also constructed as a formation of casting 100. Because of the higher strength of titanium relative to aluminum, and because of the greater design possibilities offered by the casting method, wall thicknesses is generally smaller than in the case of door frame rib 100′ sown in FIG. 3, so that the total weight is reduced relative to the latter. In the assembly, e.g. in the fuselage structure sho...

second embodiment

[0040]FIG. 5 shows a perspective view of a door frame component 100 of cast titanium according to this invention. Door frame component 100 shown comprises both a door frame rib and intercostal portions 402 formed on it, which formations take the place of the separate intercostals webs 120 shown in FIGS. 1 and 2. One of intercostal portions 402 has on its end a fastening portion 404 for fastening to the closest adjacent rib. Furthermore, hinge portions 400 of casting 100, because of which the fastening of separately produces hinges is dispensed with.

[0041]Although this invention has been described above with reference to preferred exemplary embodiments, it is not limited to them but can be modified in a multitude of ways.

[0042]For example, the invention may also be applied to a freight or baggage door in which the hinges, for example, can be arranged on the upper or lower side of the door opening. The function of one or both door frame ribs can also be performed by a regular rib in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com