Exhaust gas purifying apparatus

a technology of exhaust gas purification and purification chamber, which is applied in the direction of exhaust treatment electric control, machines/engines, separation processes, etc., can solve the problems of increasing the amount, the catalyst placed in the exhaust gas purification apparatus does not adequately reach the optimum temperature, and it is difficult to use a usual ceramic support. , to achieve the effect of efficiently eliminating specified materials, increasing the size of the exhaust gas purifying apparatus, and rapid increase of the catalyst temperatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

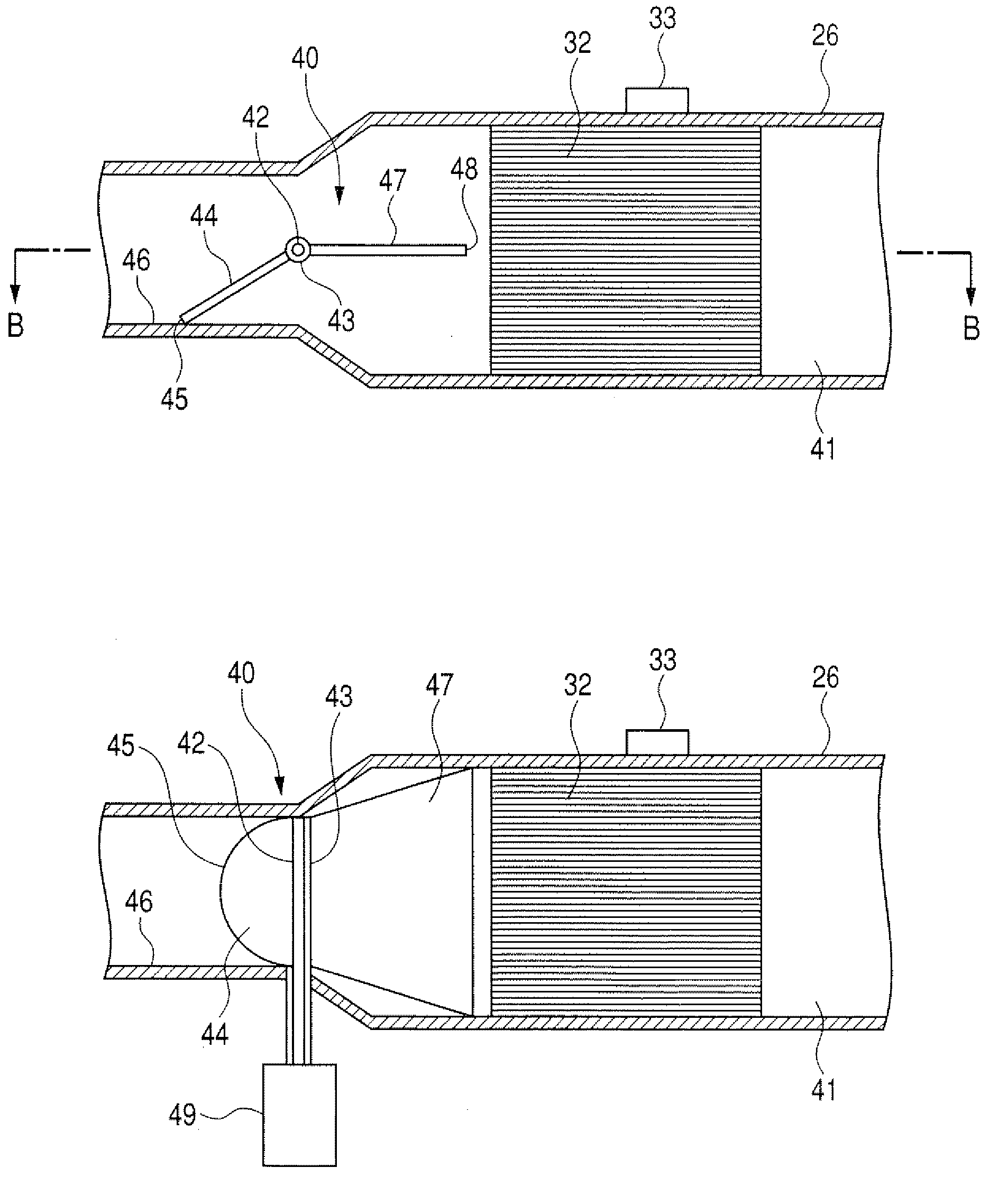

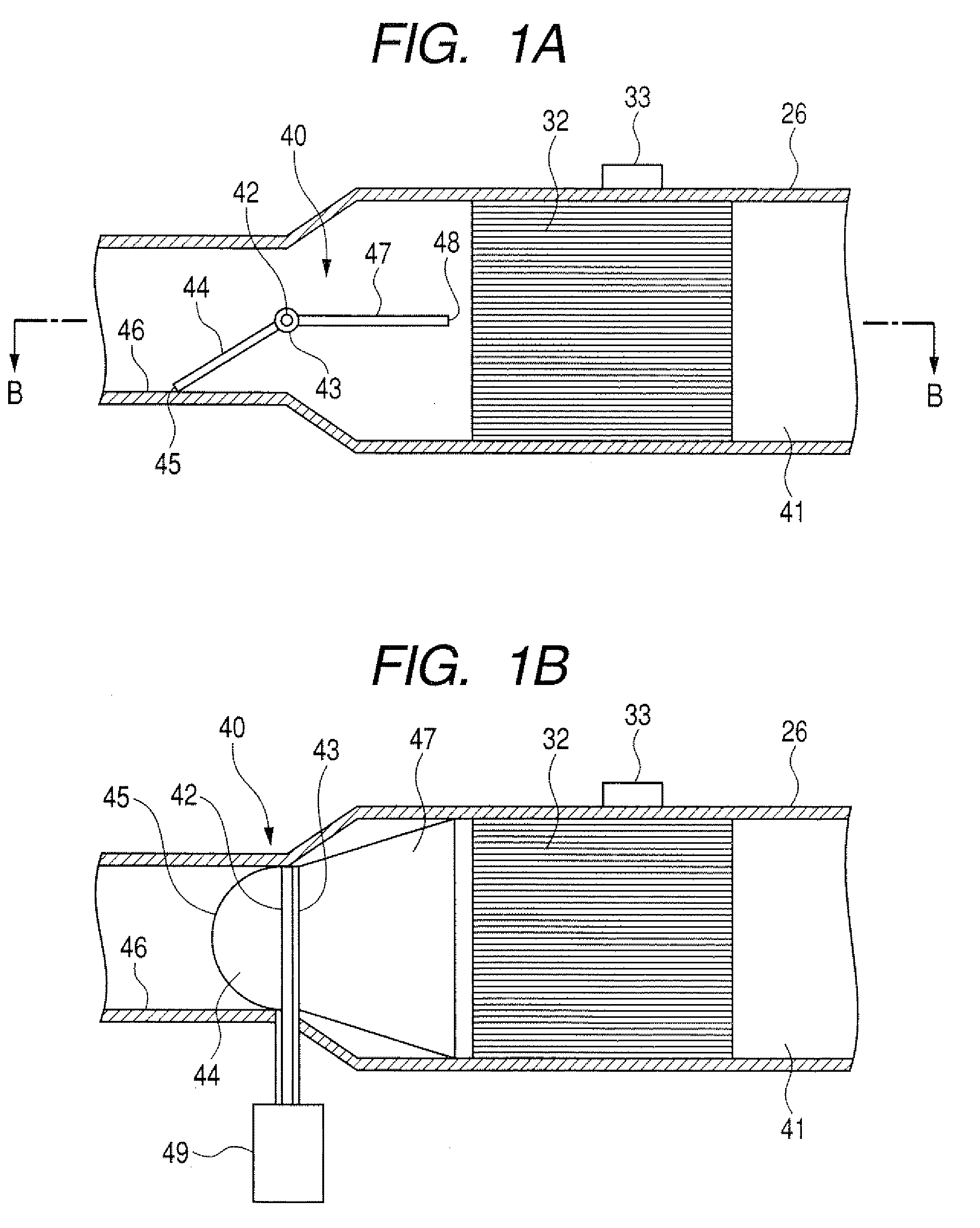

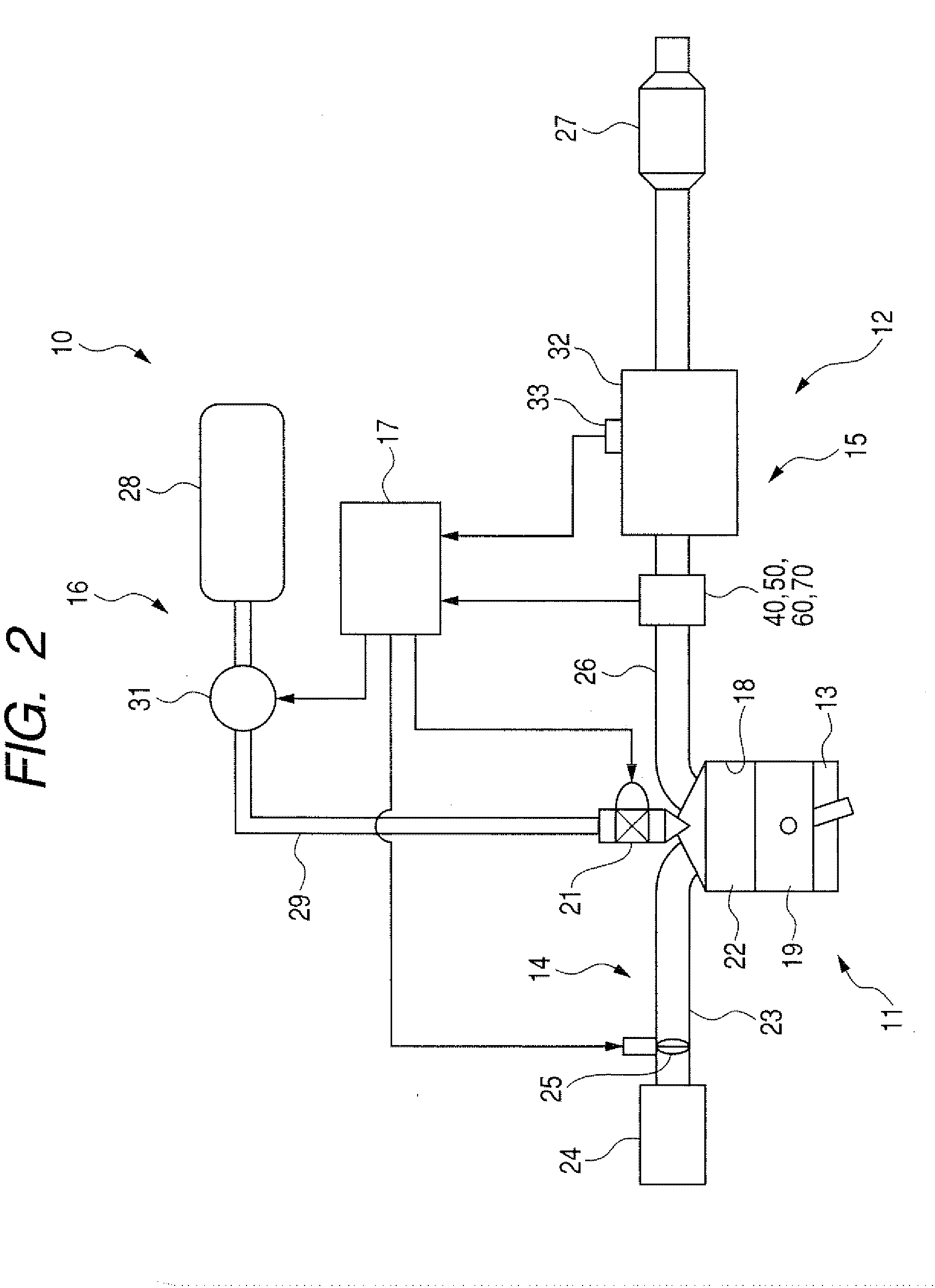

first embodiment

[0026]FIG. 2 shows a schematic diagram of an gasoline engine system as an internal combustion engine system equipped with an exhaust gas purifying apparatus according to the first embodiment of the present invention. As shown in FIG. 2, the engine system 10 has a gasoline engine 11 and an exhaust gas purifying apparatus 12. The gasoline engine 11 is comprised of an engine main system 13, an intake air system 14, an exhaust gas system 15, a gasoline supply system 16, and a control unit 17 (or an electronic control unit (ECU)).

[0027]The engine main system 13 has pistons which are located in cylinders. Each piston 13 performs reciprocating motion in the corresponding cylinder. Each cylinder 18 is equipped with an injector 21 to inject a fuel. The gasoline engine 18 uses gasoline as fuel. It is possible to use liquefied petroleum gas (LPG), liquefied natural gas (LNG), and alcohol such as ethanol instead of gasoline as fuel.

[0028]It is also possible for the engine system 10 to incorpora...

second embodiment

[0087]A description will be given of the exhaust gas purifying apparatus according to the second embodiment of the present invention with reference to FIG. 6.

[0088]FIG. 6 is a schematic cross section of a part of the exhaust gas purifying apparatus according to the second embodiment of the present invention. As shown in FIG. 6, the exhaust gas purifying apparatus 12 of the second embodiment has a throttle unit 50 instead of the throttle unit 40 according to the first embodiment. The throttle unit 50 of the second embodiment has a pair of the throttle valve members 51 and a pair of valve drive units 52. Each throttle valve member 51 is a plate shape. One end of each throttle valve member 51 is rotatably fixed to the inner wall of the exhaust gas pipe 26. That is, each exhaust gas pipe 26 rotates around a rotary shaft 53. As shown in FIG. 6, each throttle valve member 51 has a movable end part 54 which is extended toward the three way catalyst unit 32 side. According to the rotation o...

third embodiment

[0098]A description will be given of the exhaust gas purifying apparatus according to the third embodiment of the present invention with reference to FIG. 7.

[0099]FIG. 7 is a schematic cross section of a part of the exhaust gas purifying apparatus according to the third embodiment of the present invention. As shown in FIG. 7, the exhaust gas purifying apparatus of the third embodiment has a throttle unit 60 instead of the throttle units 40 and 50 of the first and second embodiments.

[0100]The throttle unit 60 has a pair of throttle valve members 61. Each throttle valve member 61 has a bimetal 62. The bimetal 62 drives the corresponding throttle valve member 61. The bimetal 62 is deformed according to the temperature change of the exhaust gas. That is, the deformation of the bimetal 62 drives a movable end part 64 of the throttle valve member 61 from the central part toward the outer part of the three way catalyst unit 32. That is, the bimetal 62 serves as a valve drive member which w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com