Method of construction for solar energy systems

a technology of solar energy and solar energy, applied in the direction of heat collector mounting/support, building repair, lighting and heating apparatus, etc., can solve the problems of limited range of motion, tracking apparatus not being able to address all arbitrary points in the sky, and limited range of desired orientations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

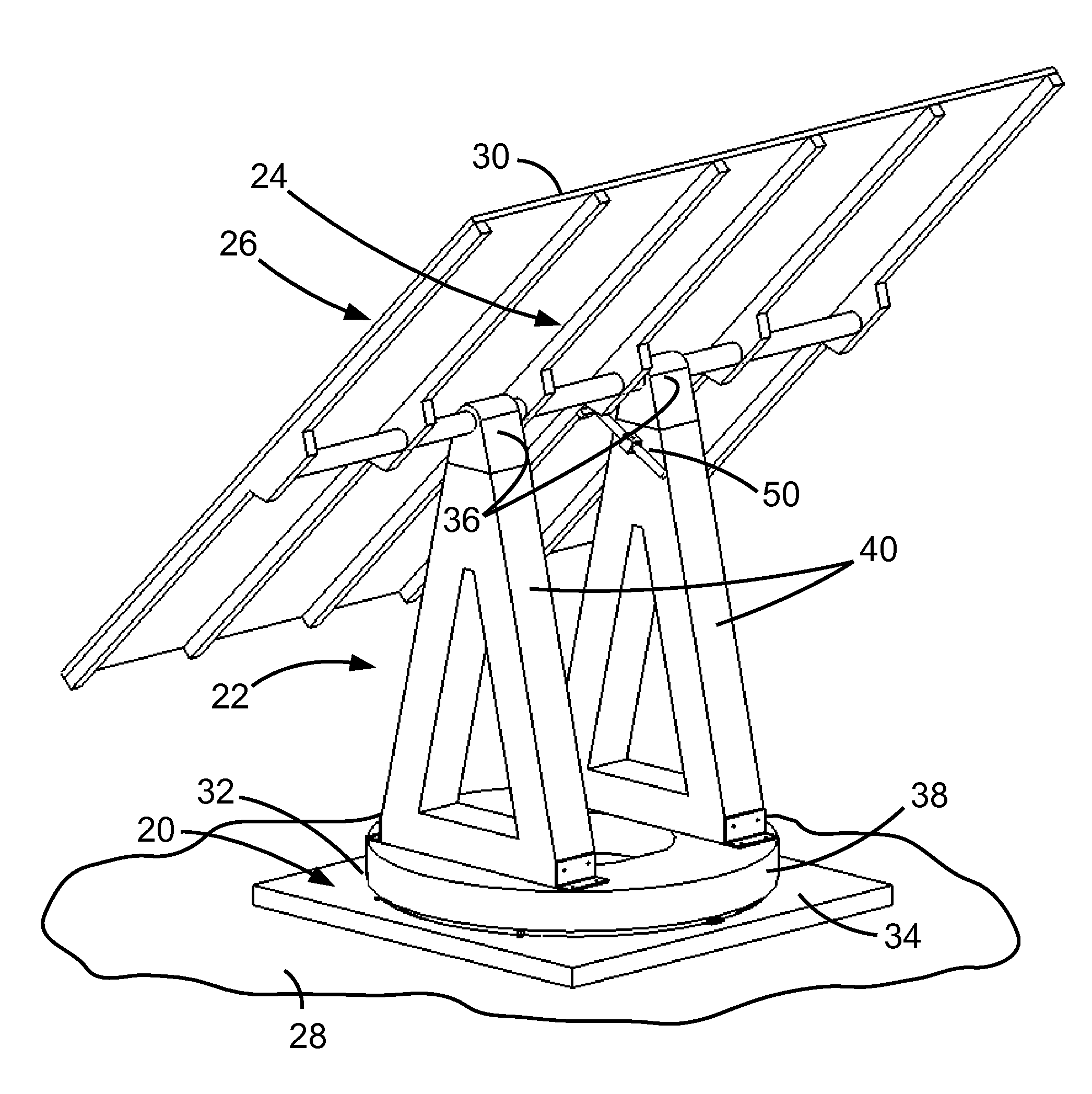

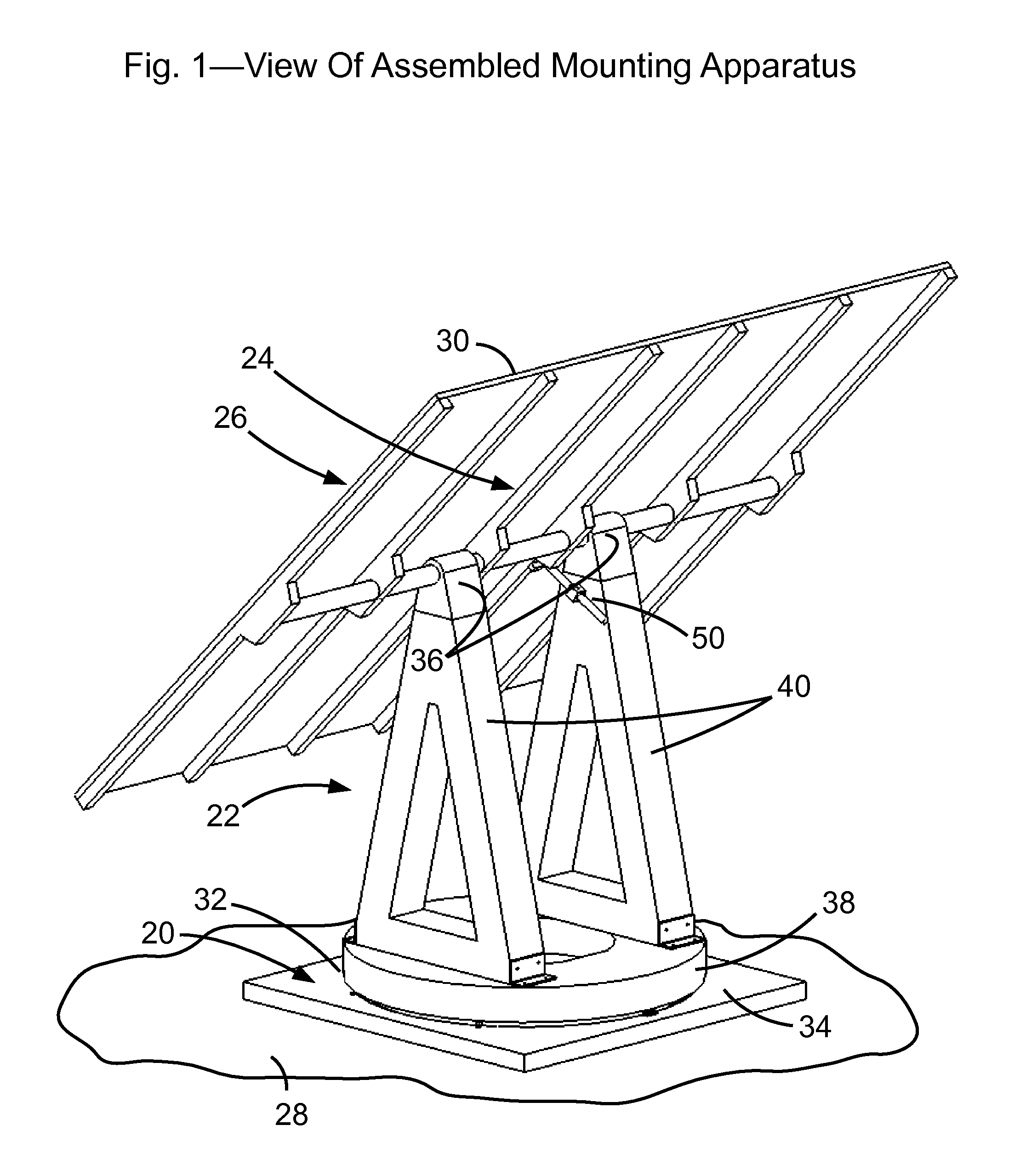

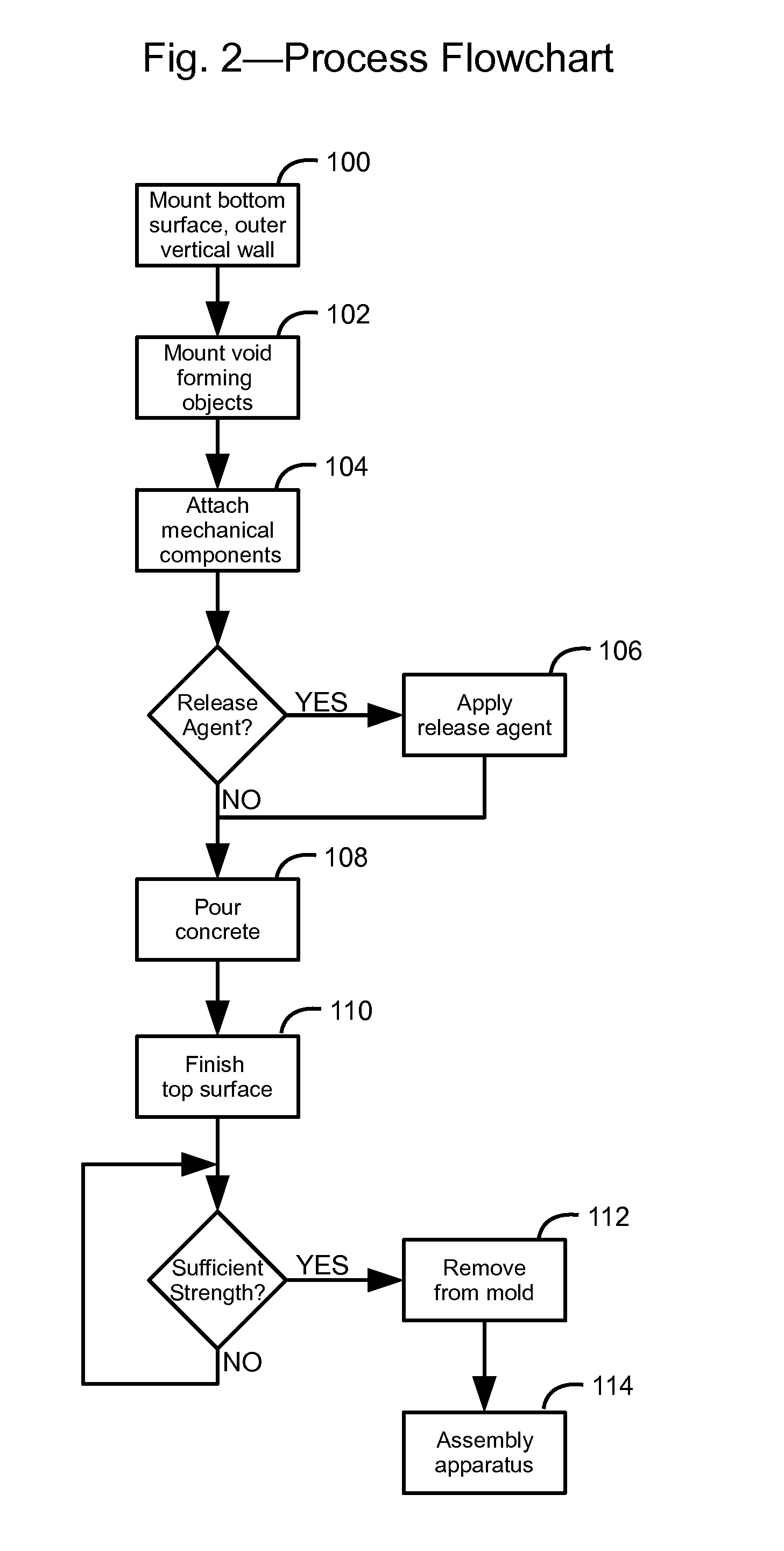

[0040]In a first embodiment, the method is shown as applied to the construction of an azimuth-elevation tracking solar energy mounting apparatus comprising a support 20, azimuth structure 22, an elevation structure 24, and a payload assembly 26. Support 20 is mounted on a mounting surface 28. payload assembly 26 is mounted on elevation structure 24. In this embodiment, mounting surface 28 is realized as the Earth. In other embodiments, mounting surface 28 could be a separate structure, such as a the roof of a dwelling. In this embodiment, payload assembly 26 comprises an array of flat plate PV module 30. In other embodiments, payload assembly 26 could be realized as any device or structure that captures, reflects, refracts, or interacts with electromagnetic energy, or any combination thereof.

[0041]In the first embodiment, support 20 comprises a concrete slab 34. Concrete slab 34 is mounted on mounting surface 28. Concrete slab 34 is pivotally coupled to azimuth structure 22 by an az...

second embodiment — figs 8-9

SECOND EMBODIMENT—FIGS 8-9

[0062]It is desirable to mold and pour azimuth ring 38 and each of azimuth truss 40 that will be assembled together in a single mounting apparatus at around the same time to allow all components to cure on approximately the same schedule and thus be ready for handling and assembly at approximately the same time. Because it can take days or weeks for concrete elements to cure sufficiently for safe handling, this means that molds for azimuth ring 38 and each of azimuth truss 40 should be constructed at the same time as well. However, depending on the relative size of concrete slab 34 compared to the area required for the three molds, there may not be enough room on concrete slab 34 to place and pour the molds on the same surface. In the second embodiment, the concrete elements are built in a stack such that both of partially cured top surface 72 of two of truss mold 74 serves to support bottom surface 44 of ring mold. More specifically, two of truss mold 74 a...

embodiments — figs 10-11

ADDITIONAL EMBODIMENTS—FIGS 10-11

[0067]In the first two embodiments, the molding and pouring process takes place on concrete slab 34 at the site where the mounting apparatus will be installed. However, in alternative embodiments, parts of the process can take place either at another location on the site or at a separate remote location.

[0068]In another embodiment, it could be advantageous to dry cast some or all of the concrete elements very early in the cure cycle. Dry casting refers to an embodiment of the process wherein azimuth ring 38 and / or each of azimuth truss 40 is partially removed from its mold extremely early in the cure cycle, even while the concrete is still in a fluid, albeit in a very stiff, highly viscous, or low slump, state. In this situation, the process is to first remove vertical mold surfaces, such as outer enclosing wall 48 and interior enclosing wall 52. Because the concrete is in a very stiff state, the concrete can maintain its shape without substantially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com