High performance nano-structured metalwood golf club heads and iron heads and components thereof

a golf club head and nano-structure technology, applied in the field of metalwood golf clubs, can solve the problems of low or poor damage response, the strength of neat plastics alone cannot replace the thin-walled titanium and steel crowns common to many designs, and the structural strength, fatigue life and maximum deflection limits of these plastic crowns are not within acceptable performance and durability limits, etc., to achieve the effect of improving the moi and even cor characteristics of the entire head, low density and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

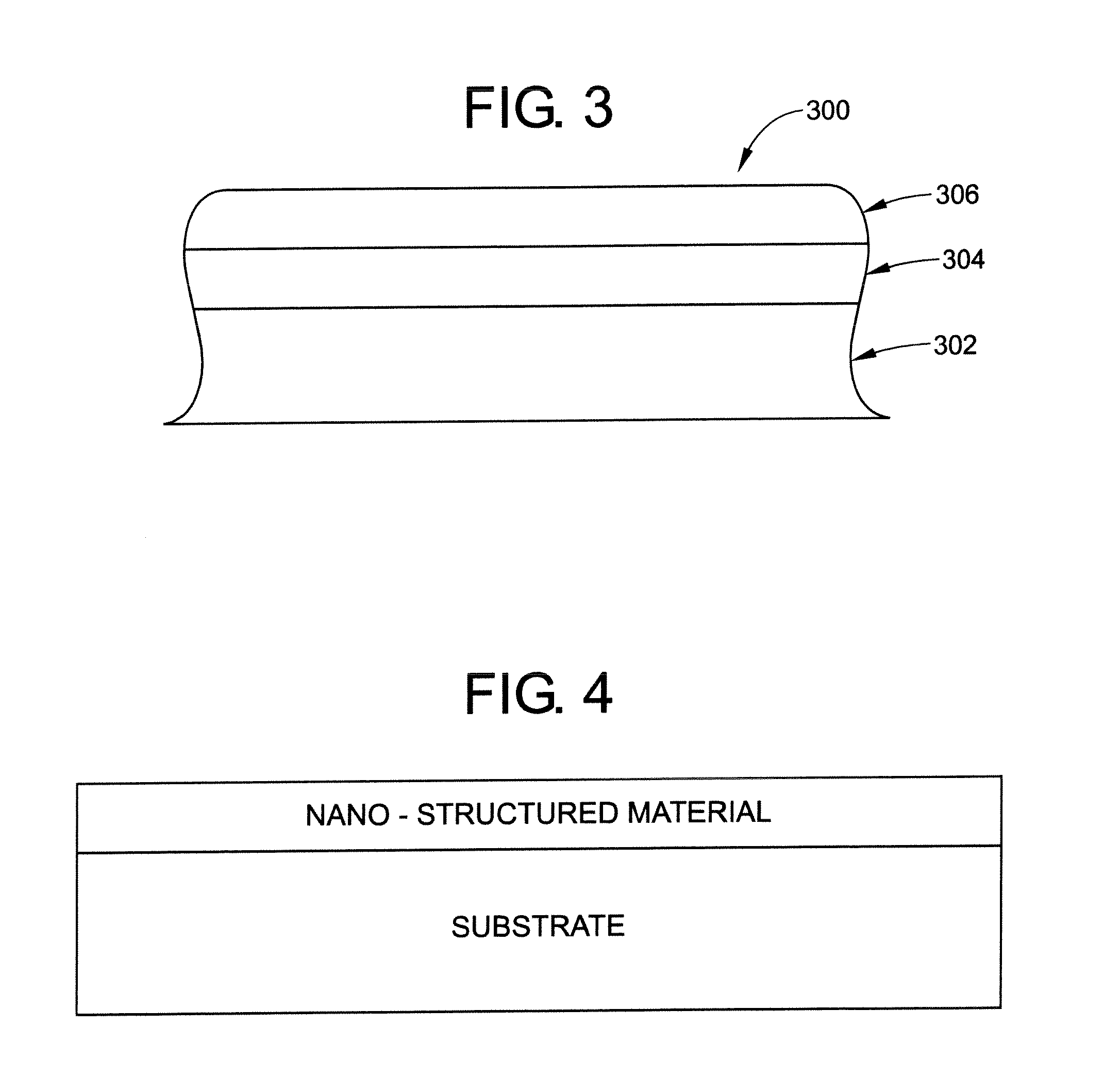

example 1

[0151]A metalwood head made from stainless steel was used as a substrate. The metalwood head was cleaned thoroughly to remove any oils and greases from the surface. Next the metalwood head was activated using a Wood's nickel bath. This process allowed a very thin layer of nickel to be deposited on the surface of the metalwood. Following this treatment, the head was immediately immersed in the nano-nickel bath. A nano-nickel layer was built up to a thickness of 100 microns. The metal wood head was assembled into a club and was field tested.

example 2

[0152]A crown for a metalwood was fabricated from a polyamide resin using injection molding process. The surface of polyamide resin crown was activated to make the surface amenable for electro deposition. The activated polyamide crown was connected to an electrical circuit and nano-nickel was deposited to a thickness of 50 microns. The nano-nickel deposited crown was subjected to an endurance and sound test. The endurance test consists of dropping a sharp dart on the crown from a pre-determined height. After the dart impacts the surface is examined for dents and other damage. A crown is considered to have passed the test if the dart drop height is more than 24 inches. The nano-nickel coated crown passed the endurance test while the non-coated crown failed the test. Additionally, the nano-nickel coated crown was judged to sound better or more metal like while the sound from a non-metal coated crown was judged poor.

[0153]Golf iron face inserts can be fabricated either individually or ...

example 3

[0163]A 12″×12″×0.060″ thick 7075-T6 aluminum plate was used as a substrate for making iron face inserts. The aluminum plate was activated prior to electro-depositing nano crystalline nickel metal. The purpose of activation is to make the aluminum surface amenable to plating. Without the activation layer the nano metal will not adhere to the aluminum surface and consequently would be rendered useless in application. The activation step consisted of cleaning, followed by double zincate followed by a nickel strike and finished with a copper strike. The copper strike protects the aluminum from corrosion and other environmental degradation. The activated aluminum plate was hooked up to an electrical circuit and nano crystalline nickel was deposited on both sides of the plate. Prior to electrodeposition of the nano-crystalline metal the copper was activated by dipping it in a suitable activator solution. Exact shapes corresponding to the face insert geometry were cut out from the plate u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com