Protection Device

a protection device and polymer technology, applied in the direction of resistor details, protective switch details, relay details, etc., can solve the problems of large device itself, inconvenient use of ptc devices in mobile electronic devices, and inability to sense relatively low abnormal elevated temperatures. , to achieve the effect of simple construction and large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

Example 1

Manufacturing of Protection Device

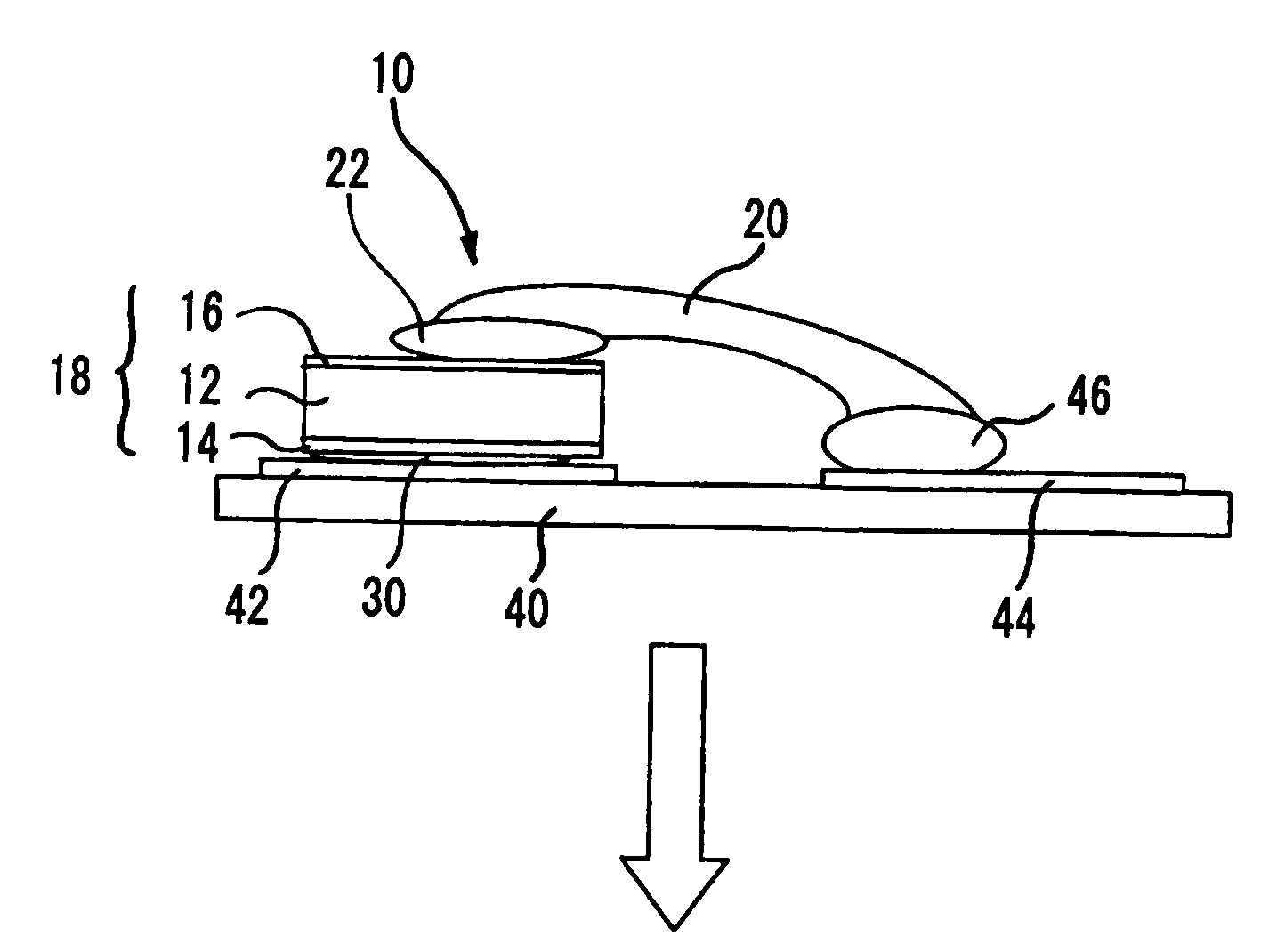

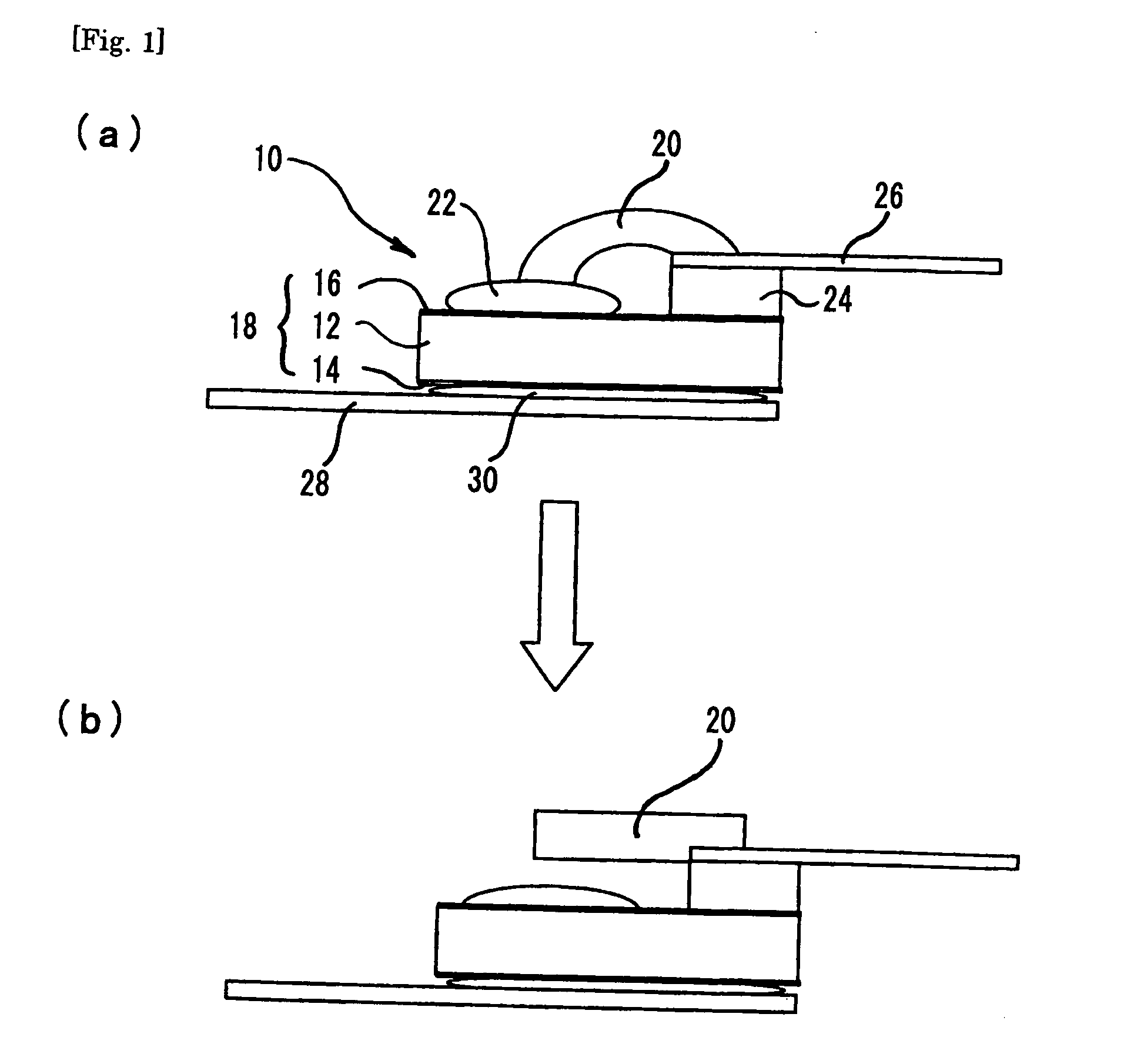

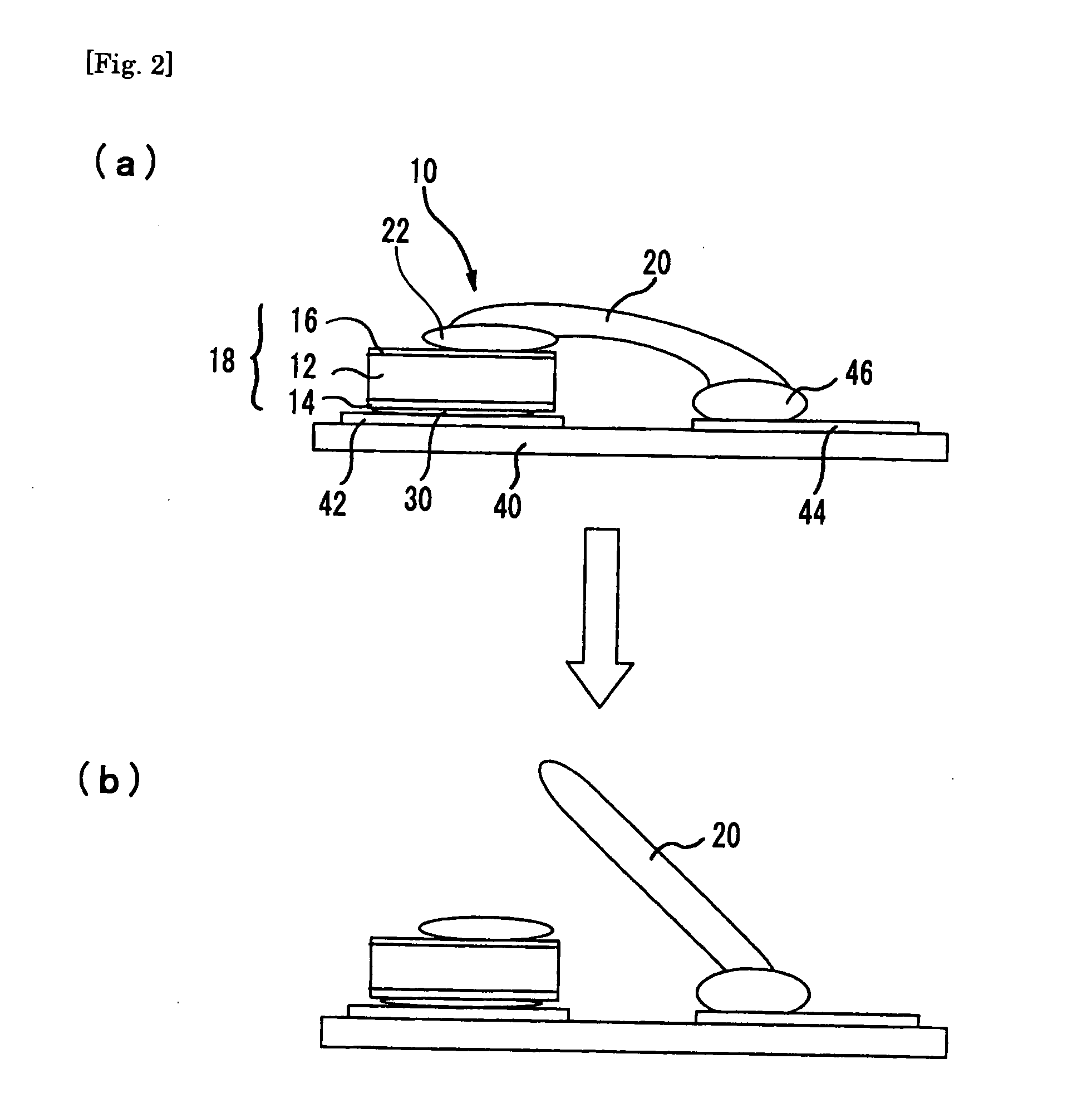

[0042]Using the elements below, the protection device of the present invention was connected to a wiring substrate, as shown in FIG. 2(a) (however, only the shape of the shape memory alloy lead is different, as described below):

(1) Polymer PTC Device (manufactured by Tyco Electronics Raychem K.K.)[0043]Product name: PolySwitch (holding current capacity: 2.0 A (at 70° C.), trip temperature: 125° C.)[0044]Size: 3.4 mm×3.6 mm (thickness 0.5 mm)[0045]Polymer PTC element (polyethylene+nickel filler)[0046]Metal electrode: gold-plated nickel (thickness: 0.03 μm)

(2) Shape memory alloy lead (manufactured by K.K. Furukawa Techno Material, Ni—Ti—Cu)[0047]Product name: NT Alloy[0048]Size: OD 0.75 mm×approx. 10 mm[0049]Shape: Linear wire shape before recovery->bent wire shape after recovery[0050]Recovery temperature: 80° C.

(3) Conductive adhesive (manufactured by Fujikura Chemical)[0051]Product name: Dotite D-500[0052]Thermoplastic resin: acrylic resin...

example 2

Confirmation of Action of Protection Device

[0056]When current at 20 A / 6V was applied at 25° C. to the substrate provided with the protection device as described above, the polymer PTC device 18 tripped, after which the shape memory alloy lead was actuated by the heat generated by the polymer PTC device, and the current flowing through the circuit was substantially cut off.

[0057]When current at 100 mA / 6V (the PTC device never trips under this conditions) was passed through another substrate provided with the protection device as described above and the temperature around the substrate raised gradually from 50° C.; so that the ambient temperature reached 80° C., the circuit in which the protection device was inserted was opened as the linear shape memory alloy lead recovered and became bent, thus separating from the electrically conductive adhesive 22 (see FIG. 2(b); it is noted that the shape of the lead 20 is bent).

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery temperature | aaaaa | aaaaa |

| recovery temperature | aaaaa | aaaaa |

| recovery temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com