Lubricating oil compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

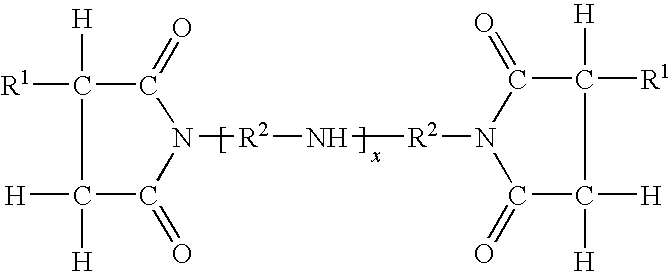

Method used

Image

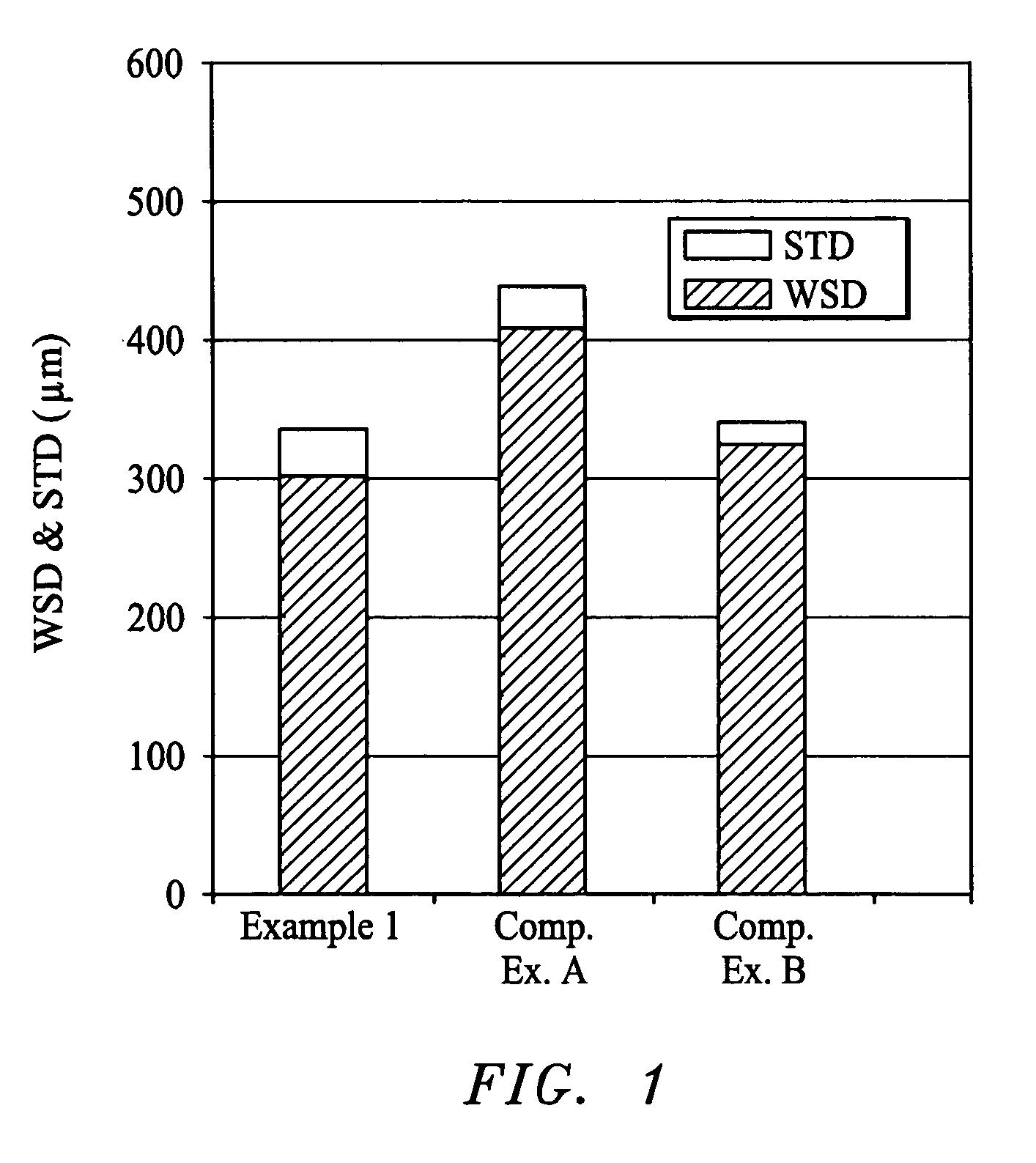

Examples

example 1

[0079]A lubricating oil composition was formed containing 3.858 wt. % of an ethylene carbonate post-treated bis-succinimide prepared from a 2300 average molecular weight polyisobutenyl succinic anhydride with a heavy polyamine, 0.286 wt. % borated glycerol monooleate friction modifier, 0.487 wt. % molybdenum succinimide dispersant / wear inhibitor, 0.490 wt. % diphenylamine antioxidant, 0.593 wt. % 17 TBN calcium sulfonate detergent, 1.141 wt. % 410 TBN calcium sulfonate detergent, 0.050 wt. % silicone-based foam inhibitor, 0.537 wt. % Exxon 100 N diluent oil and 4.800 wt. % ethylene-propylene copolymer viscosity index improver, in 87.46 wt. % Group II base oil. The resulting lubricating oil composition had a phosphorus content of 0 wt. % and a sulfur content of 0.051 wt. %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com