Semiconductor laser with low relative intensity noise of individual longitudinal modes and optical transmission system incorporating the laser

a diode laser and semiconductor technology, applied in the field of semiconductor diode lasers, can solve the problems of high cost, large footprint, and difficulty in building arrays of single-frequency lasers, and achieve the effects of low relative intensity noise (rin), low bit error rate, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

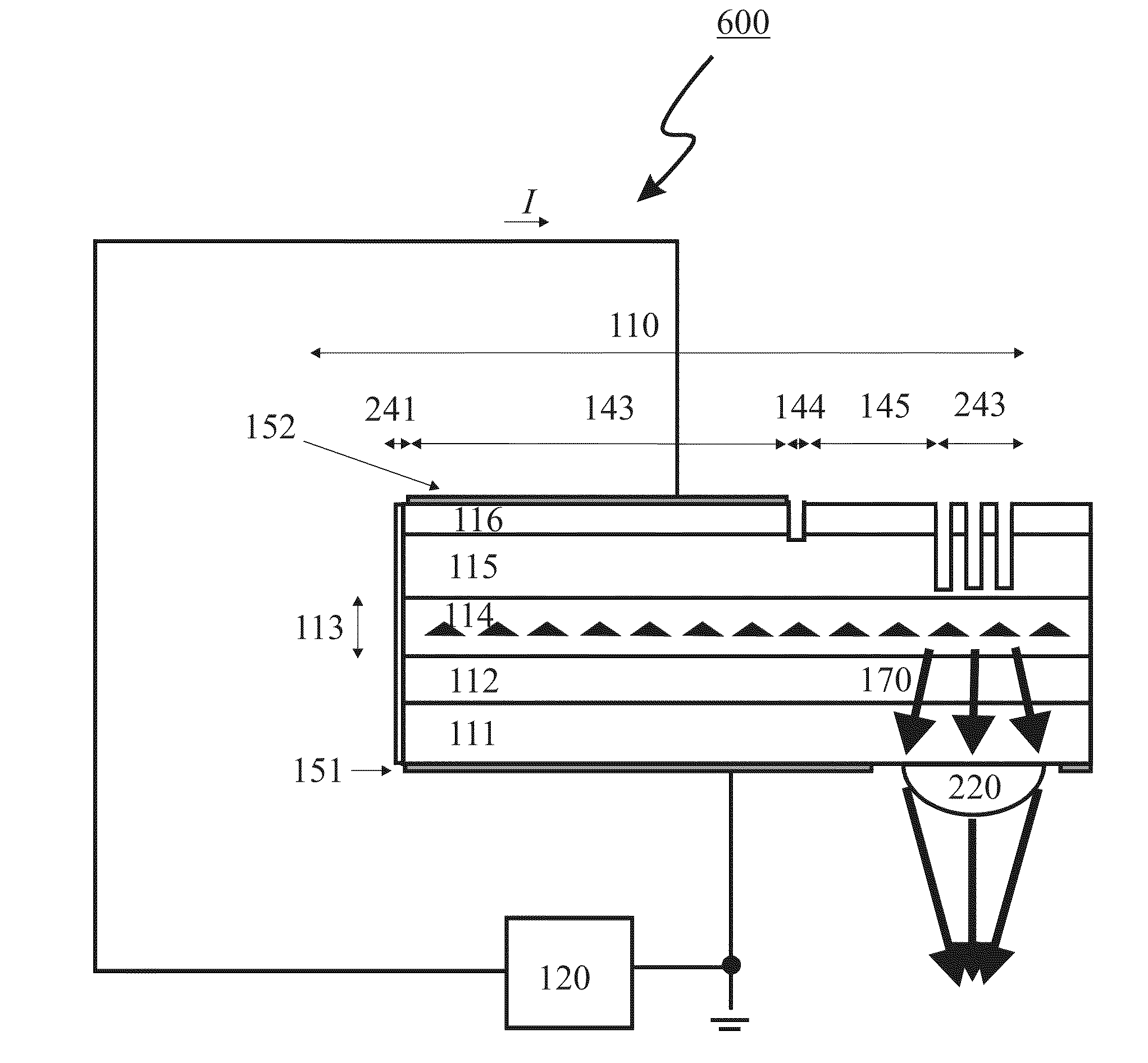

[0108]In one example, the laser active region represents ten identical planes of self-organized quantum dots. Each quantum dot plane was formed by epitaxial deposition of 0.8 nm-thick InAs insertions covered with In0.15Ga0.85As capping layers and embedded into a GaAs matrix. The laser structure has a 0.44 μm-thick GaAs / Al0.25Ga0.75As waveguide. The laser represents an edge-emitting Fabry-Perot laser in a pigtailed package. A pigtailed package is a standard laser package having an optical fiber for outputting the laser radiation. The epitaxial wafer was processed into ridge lasers. The active section length was 690 μm and the integrated noise reducing section length was varied within the range of 50-150 μm. The front mirror was as cleaved, and a high reflection coating (99% reflectivity) was formed on the back mirror. An important difference between this device and the device described in U.S. patent application Ser. No. 11 / 938,472 and Gubenko et al. is the noise reducing section.

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com