[0017]The primary objective of the present invention is to provide the electroplating solution for manufacturing the nanometer platinum and platinum based alloy particles and the method thereof. That is, an acid solution having citric acid with a suitable concentration is provided to be as an electroplating solution while in an electroplating process. The citric acid is both a dispersant and a stabilizer and nanometerizes the platinum and platinum based alloy particles deposited on the surfaces of electrodes under the condition of not affecting the oxidation reaction of platinum and

transition metal complex compound on the surfaces of the electrodes, wherein the oxidation reaction is the reduction of

metal ions, and a better

dispersity is achieved in order to break through a

bottle neck that the catalyst

metal particles in the electroplating process cannot be nanometerized. Such that, the application of the catalyst electrodes of a fuel

cell can maximized.

[0018]The secondary objective of the present invention is to provide the electroplating solution for manufacturing the nanometer platinum and platinum based alloy particles and the method thereof. That is, an acid solution having citric acid and

lactic acid with a suitable concentration is provided to be as an electroplating solution while in an electroplating process. The citric acid is both a dispersant and a stabilizer and nanometerizes the platinum and platinum based alloy particles deposited on the surfaces of electrodes under the condition of not affecting the oxidation reaction of platinum and

transition metal complex compound on the surfaces of the electrodes, wherein the oxidation reaction is the reduction of metal ions, and a better

dispersity is achieved in order to break through a

bottle neck that the catalyst metal particles in the electroplating process cannot be nanometerized. Such that, the application of the catalyst electrodes of a fuel

cell can maximized.

[0019]The third objective of the present invention is to provide the electroplating solution for manufacturing the nanometer platinum and platinum based alloy particles and the method thereof. That is, an acid solution having citric acid and

boric acid with a suitable concentration is provided to be as an electroplating solution while in an electroplating process. The citric acid is both a dispersant and a stabilizer and nanometerizes the platinum and platinum based alloy particles deposited on the surfaces of electrodes under the condition of not affecting the oxidation reaction of platinum and

transition metal complex compound on the surfaces of the electrodes, wherein the oxidation reaction is the reduction of metal ions, and a better dispersity is achieved in order to break through a

bottle neck that the catalyst metal particles in the electroplating process cannot be nanometerized. Such that, the application of the catalyst electrodes of a fuel cell can maximized.

[0020]The fourth objective of the present invention is to provide the electroplating solution for manufacturing the nanometer platinum and platinum based alloy particles and the method thereof. That is, an acid solution having citric acid and

sulfuric acid with a suitable concentration is provided to be as an electroplating solution while in an electroplating process. The citric acid is both a dispersant and a stabilizer and nanometerizes the platinum and platinum based alloy particles deposited on the surfaces of electrodes under the condition of not affecting the oxidation reaction of platinum and transition metal complex compound on the surfaces of the electrodes, wherein the oxidation reaction is the reduction of metal ions, and a better dispersity is achieved in order to break through a

bottle neck that the catalyst metal particles in the electroplating process cannot be nanometerized. Such that, the application of the catalyst electrodes of a fuel cell can maximized.

[0021]The fifth objective of the present invention is to provide the electroplating solution for manufacturing the nanometer platinum and platinum based alloy particles and the method thereof. That is, an acid solution having citric acid and glycol with a suitable concentration is provided to be as an electroplating solution while in an electroplating process. The citric acid is both a dispersant and a stabilizer and nanometerizes the platinum and platinum based alloy particles deposited on the surfaces of electrodes under the condition of not affecting the oxidation reaction of platinum and transition metal complex compound on the surfaces of the electrodes, wherein the oxidation reaction is the reduction of metal ions, and a better dispersity is achieved in order to break through a

bottle neck that the catalyst metal particles in the electroplating process cannot be nanometerized. Such that, the application of the catalyst electrodes of a fuel cell can maximized.

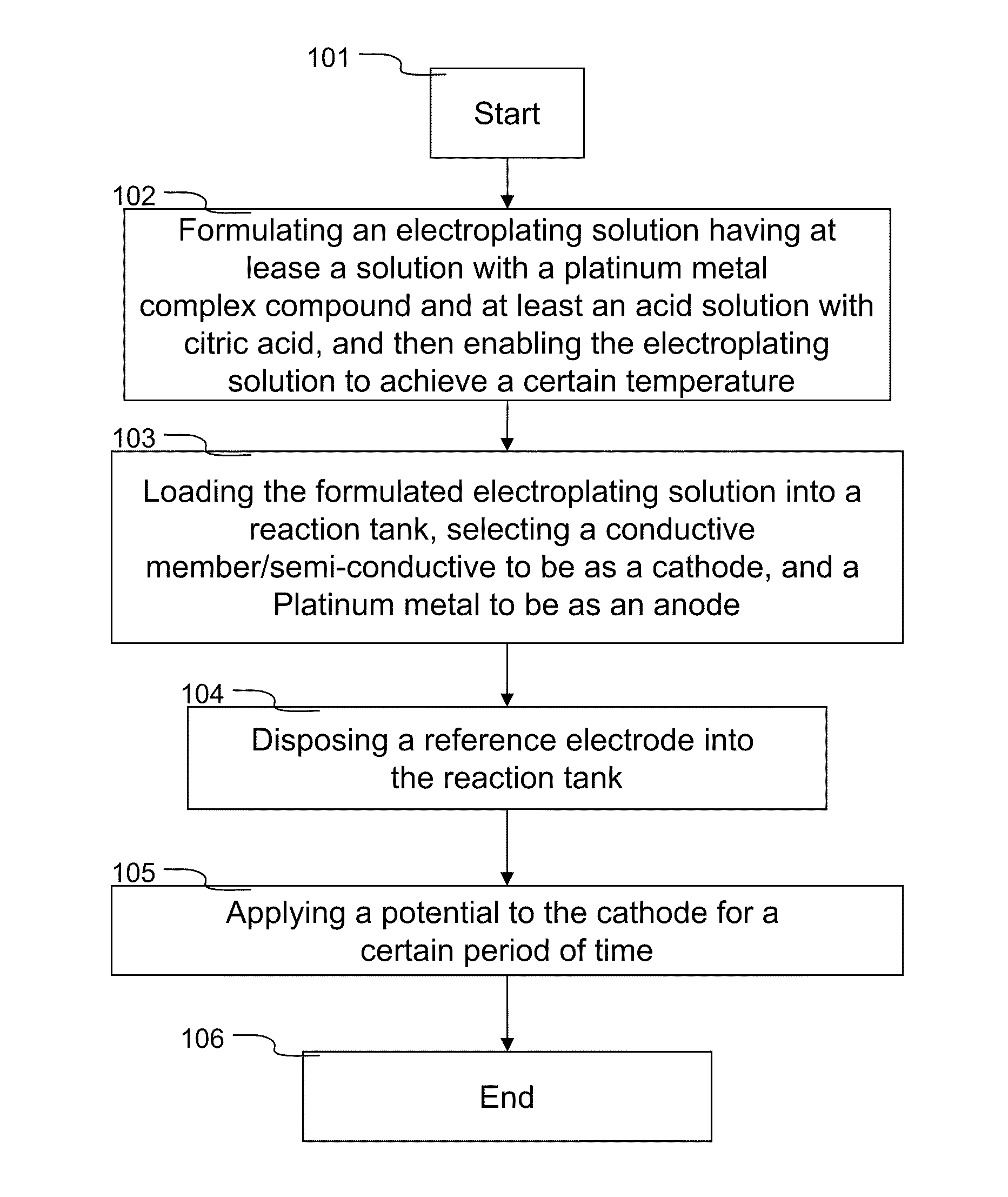

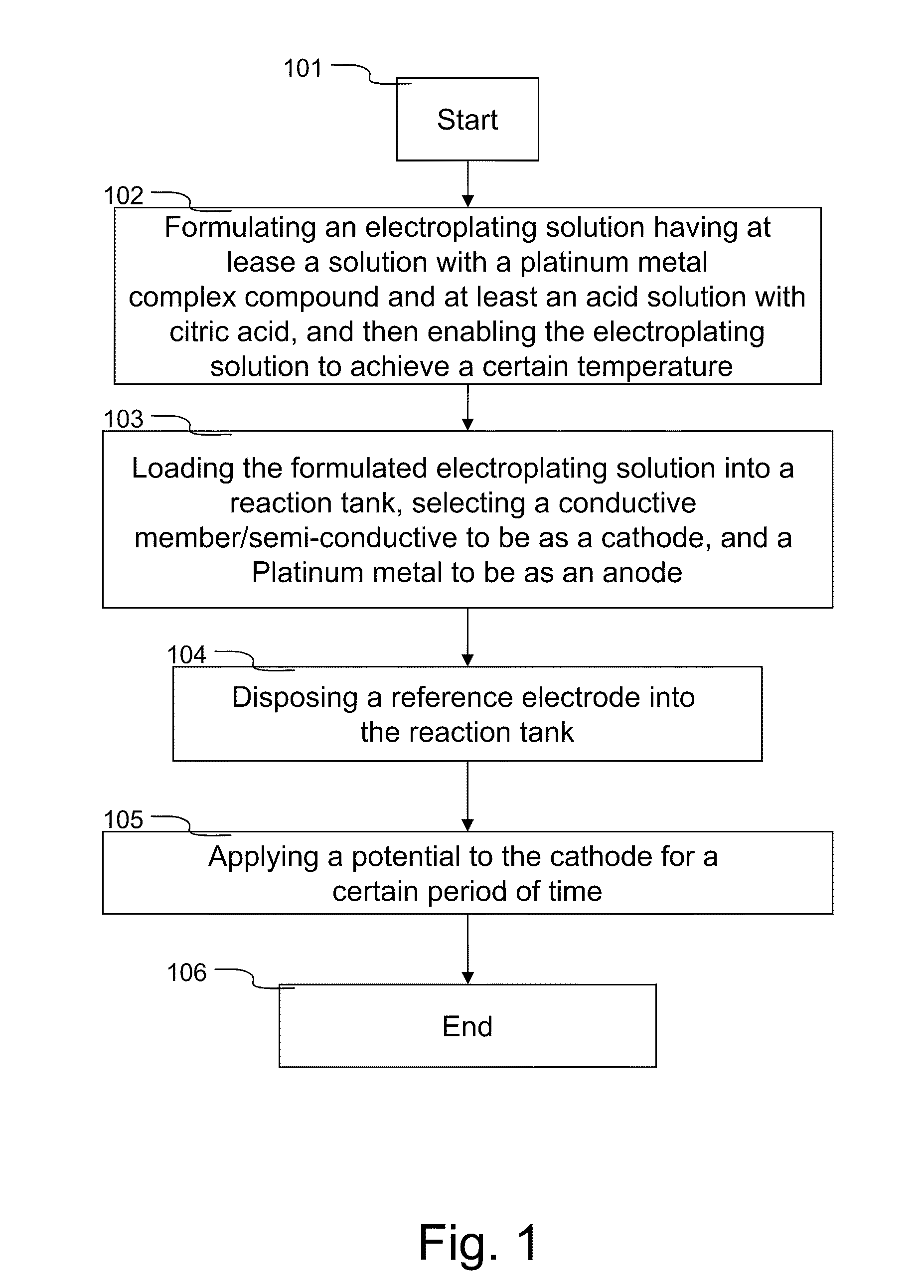

[0022]The sixth objective of the present invention is to provide the electroplating solution for manufacturing the nanometer platinum and platinum based alloy particles and the method thereof. That is, an electroplating solution having at least citric acid is provided into a reaction tank, continuously a suitable

cathode and

anode are selected, and then a suitable potential is applied, so that the best nanometer platinum and platinum based alloy particles can be made.

Login to View More

Login to View More