Substrate cleaning method for removing oxide film

a cleaning method and oxide film technology, applied in semiconductor devices, electric discharge tubes, chemical instruments and processes, etc., can solve the problems of large apparatus, inability to completely remove watermarks, and inability to control the etching of very thin oxide films, so as to reduce native oxide films and organic impurities, and improve the flatness of substrate surfaces. , the effect of reducing the flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069]Examples of the present invention will be described below.

[0070]Embodiments of the present invention will be described below referring to the drawings.

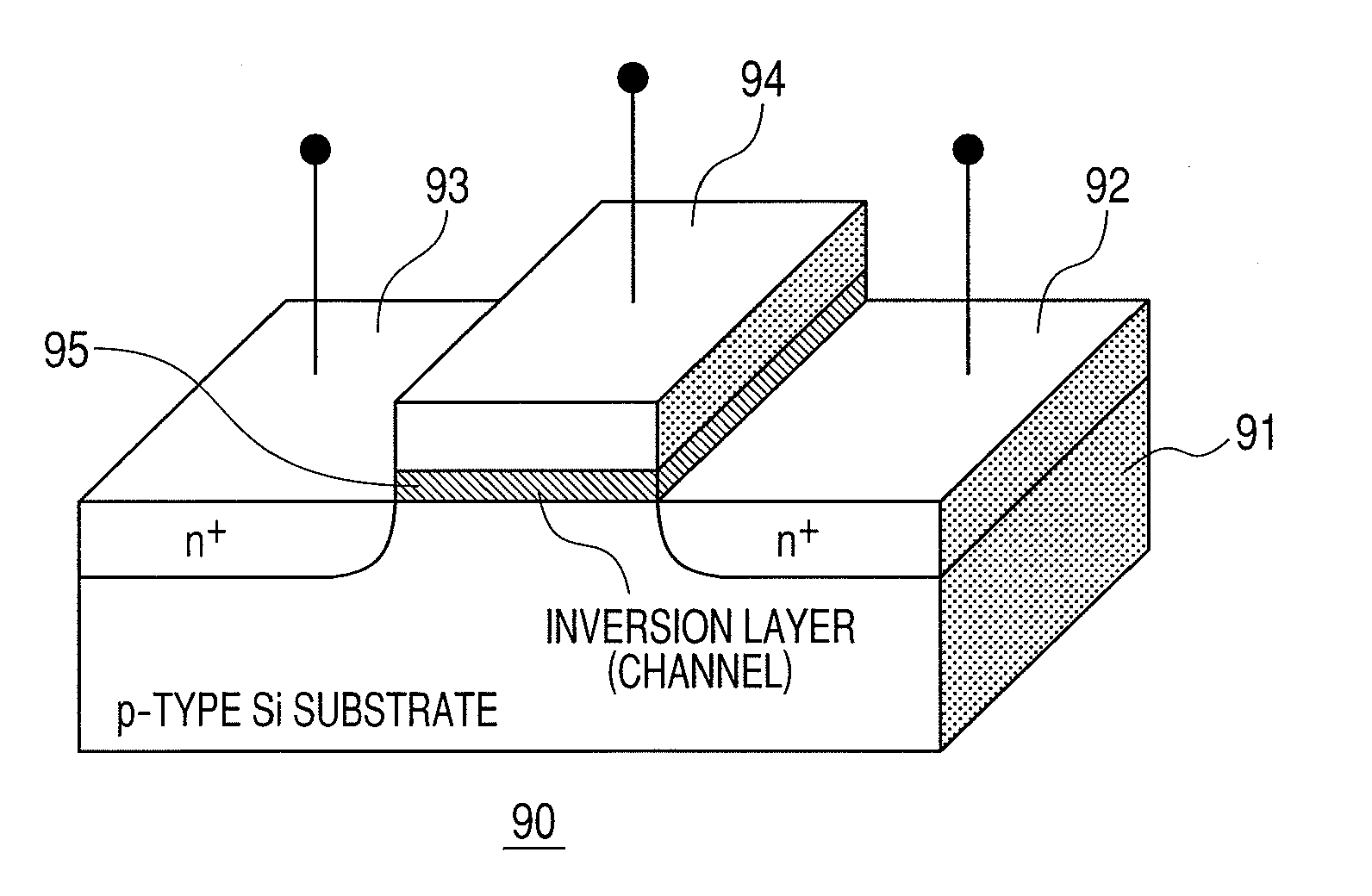

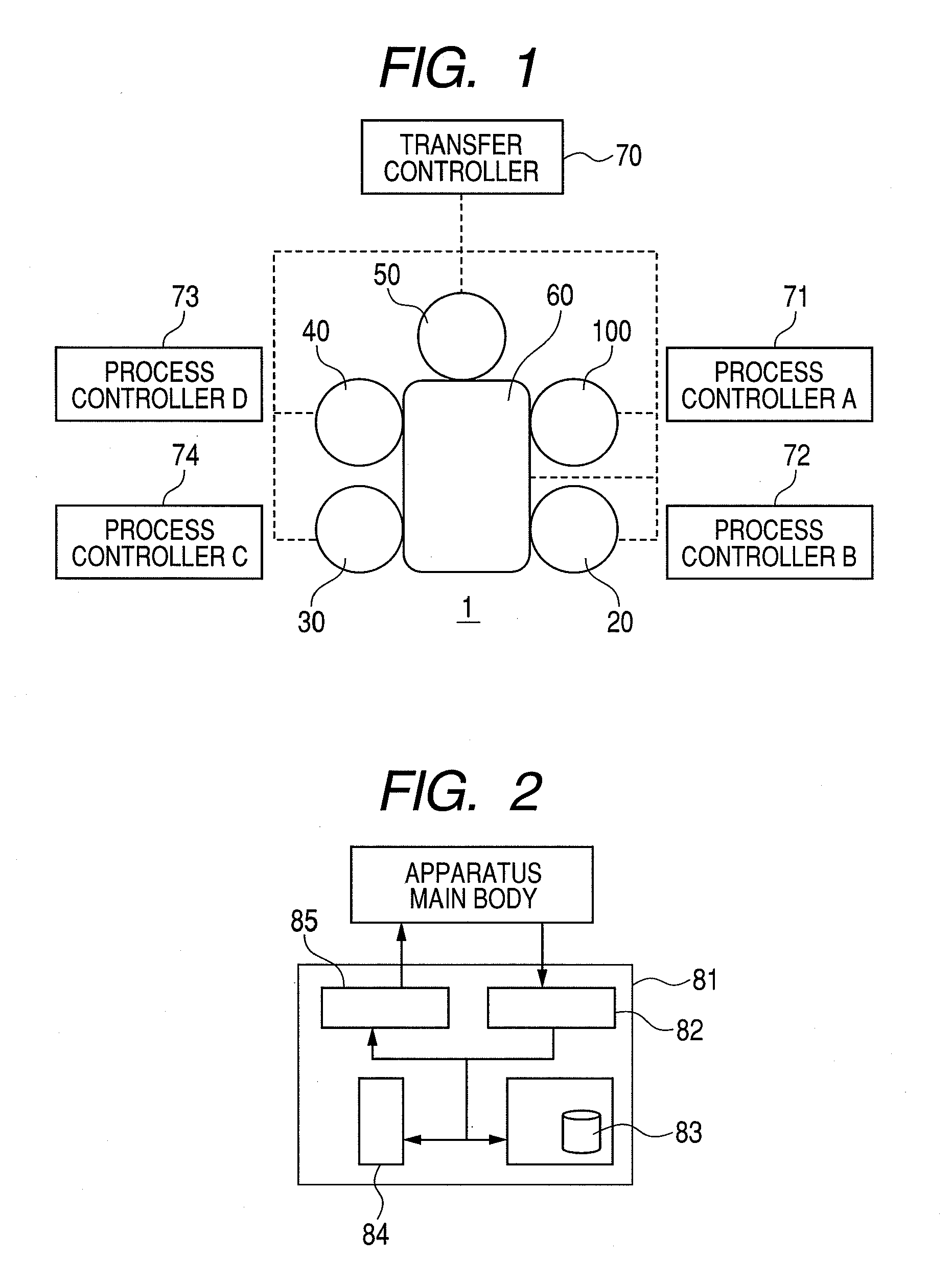

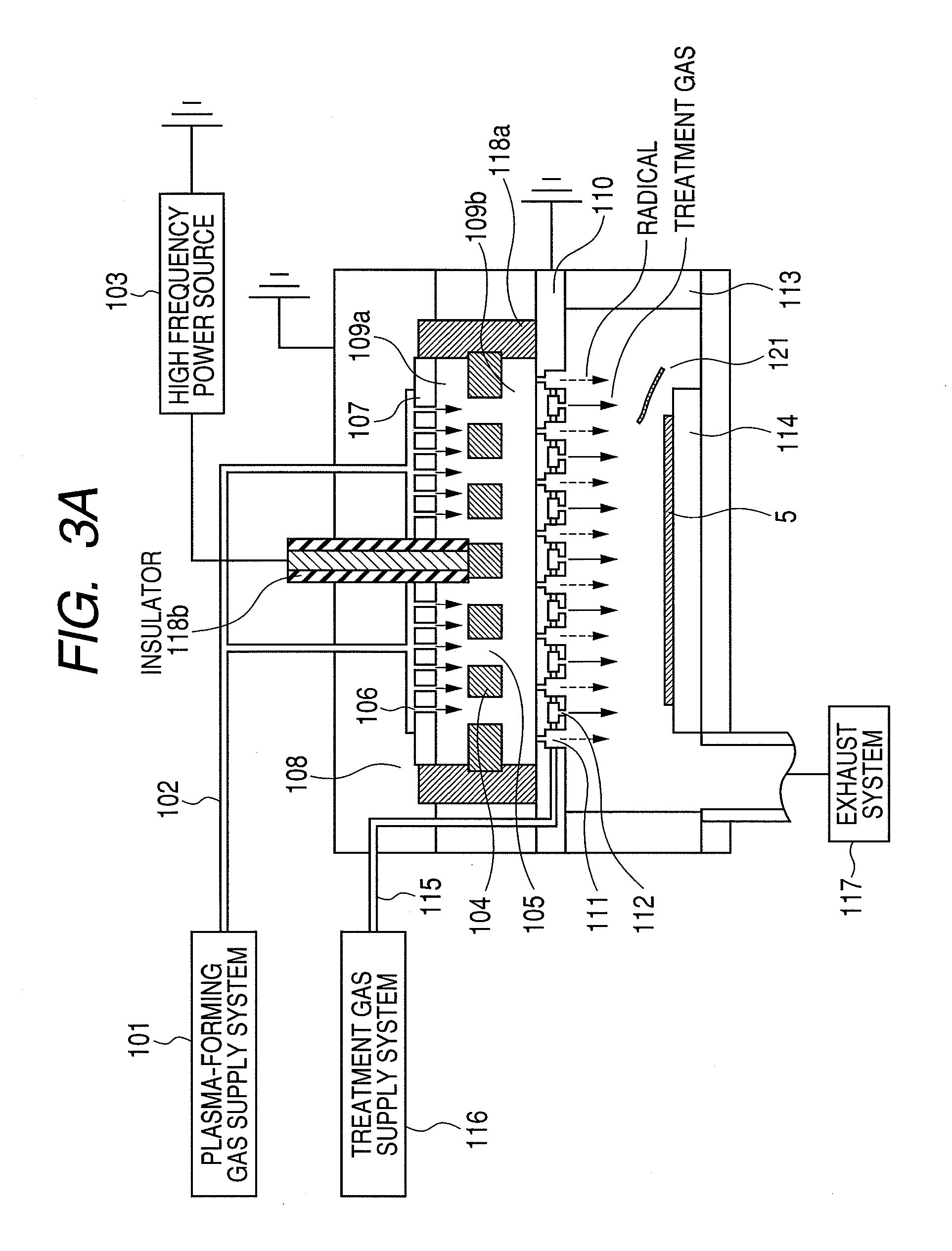

[0071]The examples deal with the cases of applying the present invention to a film-forming apparatus 1 illustrated in FIG. 1, focusing on a process of removing a native oxide film and organic matter formed on a Si substrate by the first step using a surface treatment apparatus 100 illustrated in FIGS. 3A to 3D.

[0072]A substrate 5 adopted as the sample is a Si single crystal substrate (with 300 mm in diameter) which is allowed to stand in a clean air to form a native oxide film thereon. The substrate 5 is transferred to a load-lock chamber 50 by a substrate-transfer mechanism (not shown), and is placed therein. Then, the load-lock chamber 50 is evacuated by an evacuation system (not shown). After evacuating to a desired pressure, or 1 Pa or below, a gate valve (not shown) between the load-lock chamber and a transfer chamber is op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com