Combination therapy for treating hypercholesterolemia

a hypercholesterolemia and conjugate technology, applied in the field of conjugate therapy for treating hypercholesterolemia, can solve the problems of unsatisfactory polymer efficacy, complex manufacturing process, and unpalatable polymer, and achieve the effect of reducing serum cholesterol and reducing serum cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

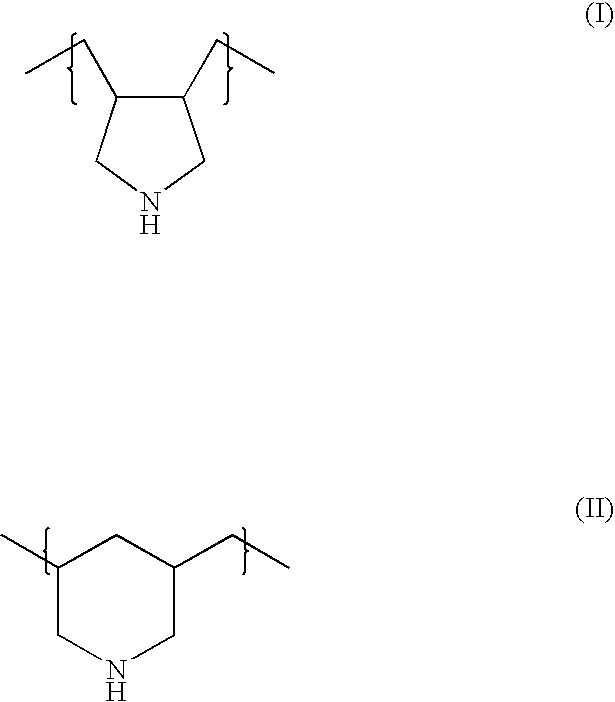

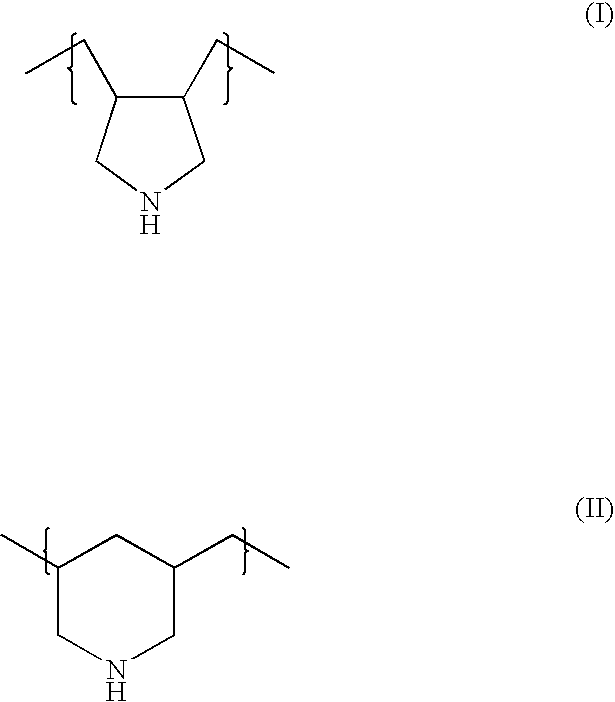

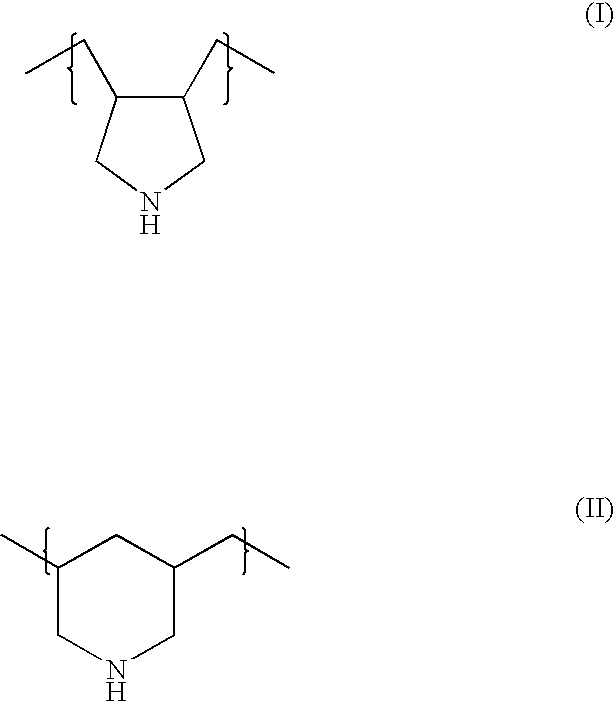

Image

Examples

example 1

Preparation of Poly(Diallylammonium Chloride)

[0056]Concentrated hydrochloric acid (507.0 g; 37%) was charged to a 5 L, 3-neck round bottomed flask and agitated with a mechanical stirrer. The flask was cooled to <5° C. with an ice bath. Diallylamine (635.0 ml) was added dropwise to the stirring hydrochloric acid over a three hour period using an addition funnel capped with a pierced rubber septum.

[0057]The stirring solution temperature was maintained at <10° C. After the addition was completed, the ice bath was removed and the mixture was allowed to warm to room temperature. Concentrated hydrochloric acid (7.3 g) was added to the solution. Water (368.7 g) was added to the solution and it was allowed to sit overnight.

[0058]The stirring solution was purged with nitrogen gas for 30 minutes at room temperature. 2,2′-Azobis[2-amidinopropane]dihydrochloride (6.87 g) was added as 34.4 g of a 20% aqueous solution. The solution was heated to 60°-80° C. for six and one-half hours. 2,2′-Azobis[...

example 2

Synthesis of Polydiallylamine

[0060]A solution of 39.3 g of an aqueous solution (68 wt %) of diallylammonium hydrochloride, 5.3 g of an aqueous solution (73 wt %) of triallylamine hydrochloride and 0.9 g of 2,2′-azobis(2-amidinopropane)dihydrochloride was bubbled with a slow stream of nitrogen for 30 minutes. While stirring, this reaction mixture was added to a solution of 7 g of polyvinylacetate in 300 mL of toluene. The resulting mixture was stirred at room temperature for 45 minutes under nitrogen atmosphere. While stirring, the temperature of the reaction mixture was raised to 60 C and was held at this temperature for 24 hours. The reaction mixture was allowed to cool to room temperature and the polymer particles were collected by filtration. While in the funnel, the filtered particles were successively washed with 300 mL of toluene and 500 mL of methanol. The polymer particles were suspended in 500 mL of methanol, stirred for 50 minutes, and filtered.

[0061]Subsequently, the part...

example 3

Cross-Linked Polydiallylamine

[0062]The polymer solution of Example 1 was crosslinked at 30 mole % as follows:

[0063]Epichlorohydrin (31.61 mL) was added to 900.0 g of the neutralized polymer solution in a glass beaker, agitated with a magnetic stirrer and covered with polyvinyl film. The gel was allowed to cure for 22 hours. The solid gel was then ground using a grinder. The ground polymer was washed in a static bed manner using a large plastic Buchner funnel lined with filter paper. A second piece of filter paper, perforated with holes, was placed on top of the polymer cake to prevent disturbing the cake when adding wash water. Fresh deionized H2O (14 L) was added to the top of the cake and drained under vacuum. The washed polymer was then transferred to glass drying trays and dried in a 60° C. forced air oven for several days. The final dry weight was 176.2 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com