Drive system for power switching elements

a technology of power switching elements and drive systems, which is applied in the direction of dynamo-electric converter control, pulse techniques, instruments, etc., can solve the problems of increasing the electric power loss generated by changing the switching speed of the switching element, and achieve the effect of reducing the total number of components of the drive system and smoothing the current flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

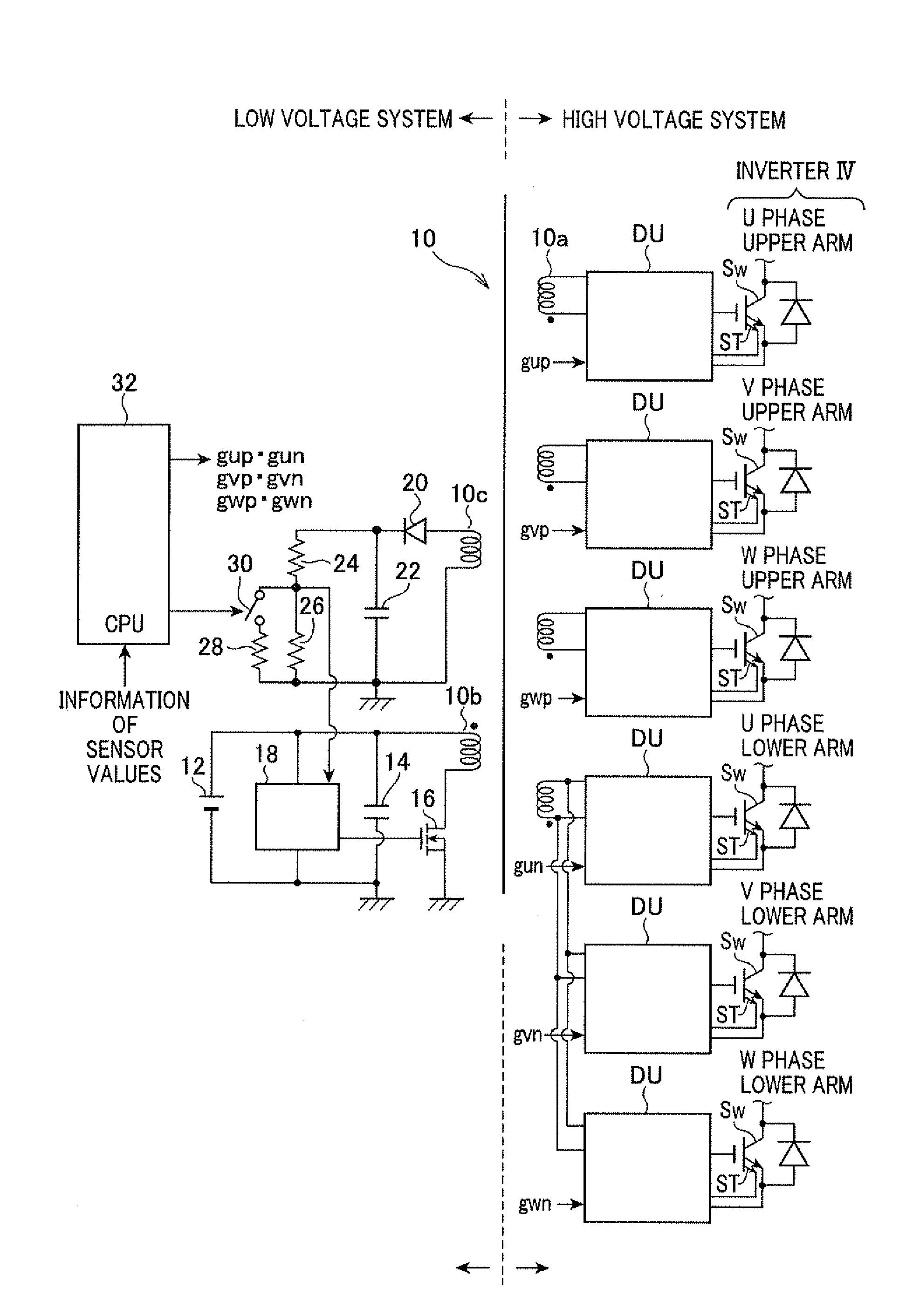

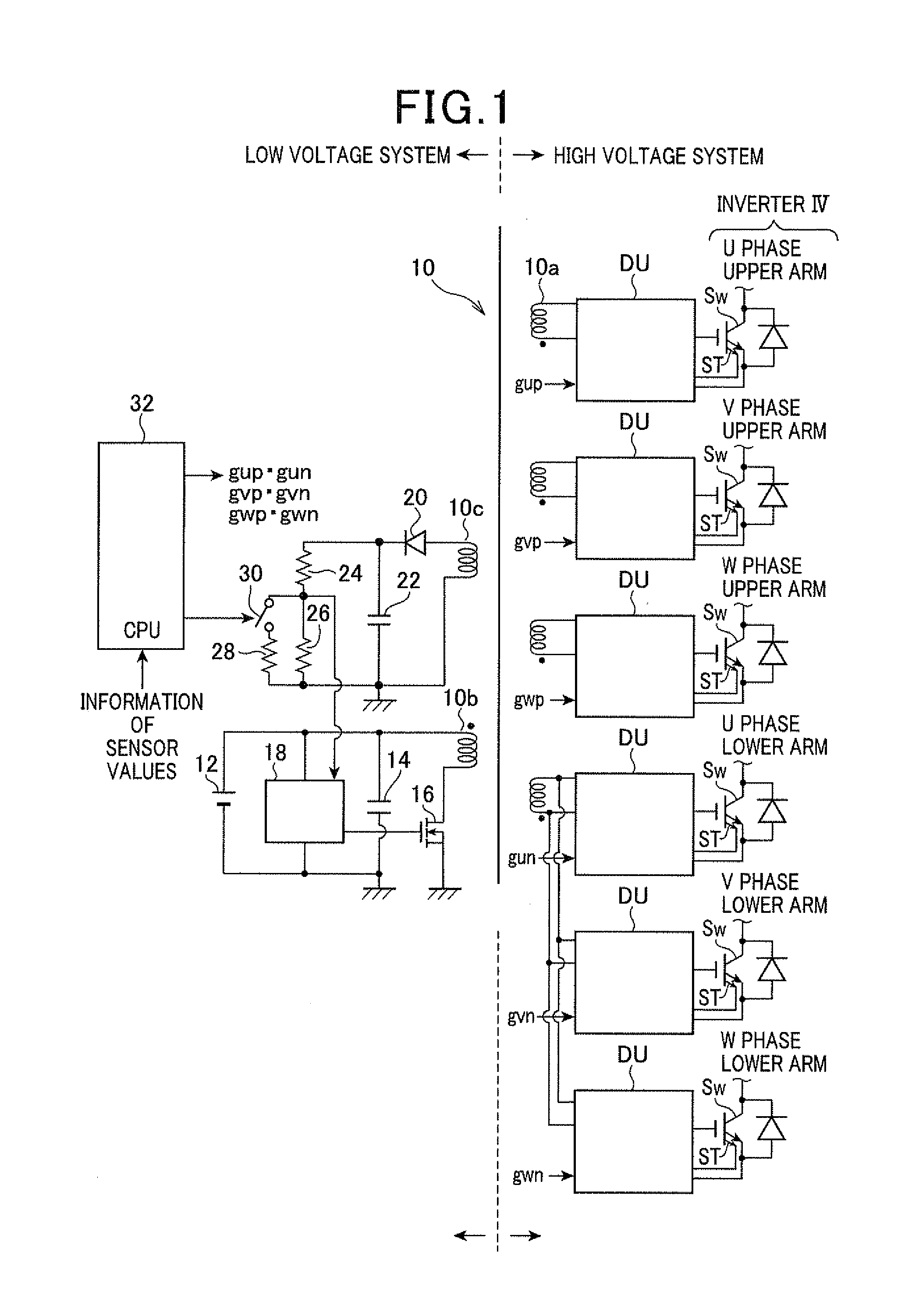

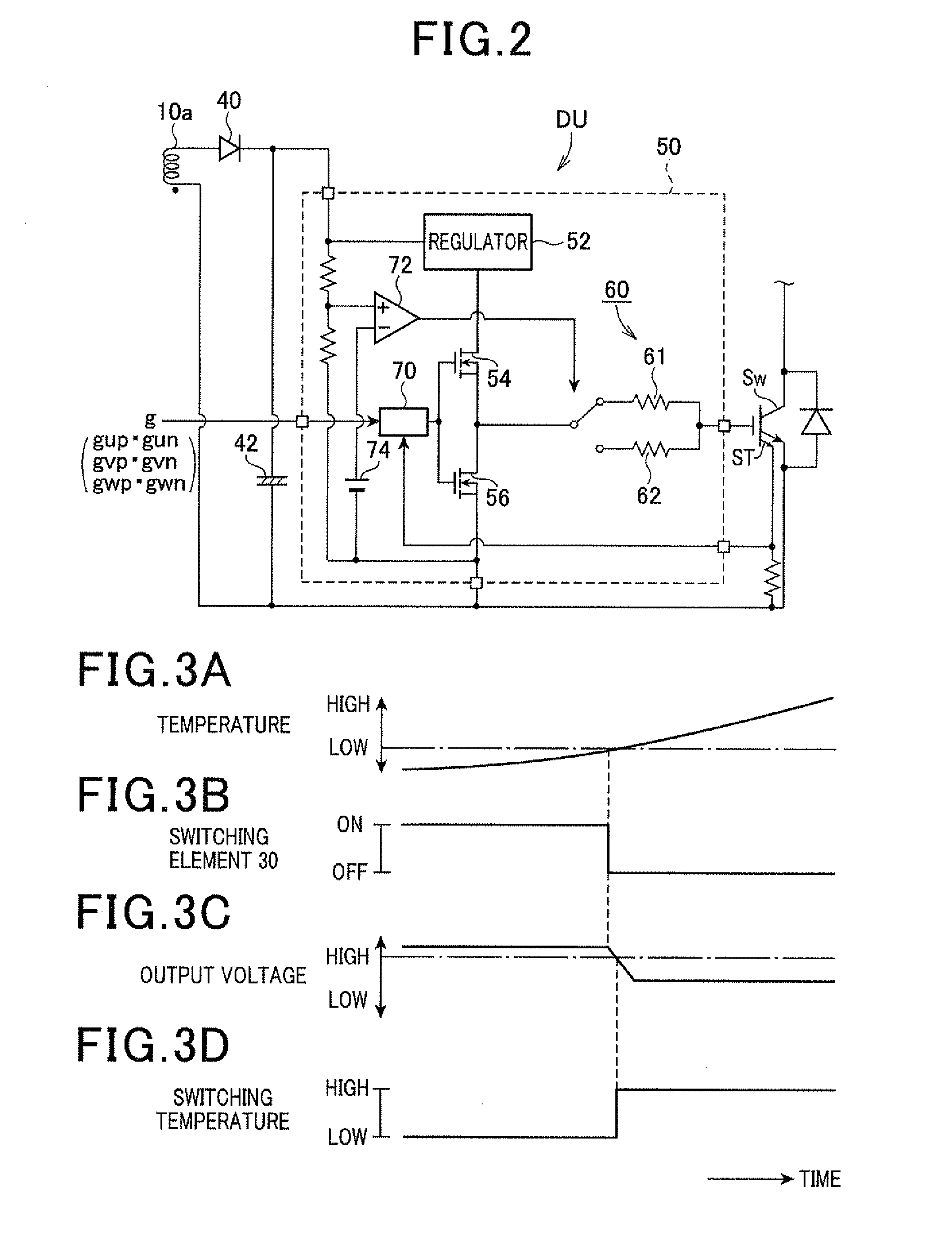

[0047]A description will be given of a drive system for changing the switching speed of power switching elements with reference to FIG. 1, FIG. 2, and FIG. 3A to FIG. 3D. For example, the drive system according to the first embodiment is mounted to various types of vehicles such as a hybrid vehicle, with reference to drawings.

[0048]A hybrid vehicle is a vehicle that uses two or more distinct power sources to move the vehicle, for example, hybrid electric vehicles (HEVs) which combine an internal combustion engine and one or more electric rotary machines such as a motor generator and an electric motor. FIG. 1 is a view showing a schematic configuration of the drive system having a plurality of the drive units DU according to the first embodiment.

[0049]As shown in FIG. 1, the drive system is comprised of a transformer 10, a low voltage system, and a high voltage system. The transformer 10 serves as an insulation means with which the low voltage system and the high voltage system are i...

second embodiment

[0084]A description will be given of the drive system for power switching elements according to the second embodiment of the present invention with reference to FIG. 4.

[0085]FIG. 4 is a view showing a circuit configuration of the drive unit DU in the drive system according to the second embodiment of the present invention. In the drive unit DU shown in FIG. 4, the same components in the drive unit DU of the first embodiment shown in FIG. 1 and FIG. 2 will be referred with the same reference numbers.

[0086]In the drive unit DU shown in FIG. 4, a switching speed change part 60-1 to change the switching speed of the power switching element Sw is composed of a gate capacitance change means.

[0087]As shown in FIG. 4, the gate capacitance change means (which serves as the switching speed change part 60-1) is composed of a capacitance 63, a switching element 64, and a capacitance 65. The capacitance 63 is connected in parallel to the switching element 64 and a capacitance 65. The switching e...

third embodiment

[0090]A description will be given of the drive unit DU for power switching elements in the drive system according to the third embodiment with reference to FIG. 5.

[0091]In the drive unit DU in the drive system according to the third embodiment, the switching means to change the switching speed of the power switching element Sw is composed of a gate voltage change means.

[0092]FIG. 5 is a view showing a circuit configuration of the drive unit DU in the drive system according to the third embodiment. In the drive unit DU shown in FIG. 5, the same components in the drive unit DU shown in FIG. 2 will be referred with the same reference numbers.

[0093]As shown in FIG. 5, the gate voltage change means is composed of a regulator 52a which is capable of changing the output voltage of the transformer 10. The regulator 52a changes the output voltage of the transformer 10 based on a difference between the output voltage of the transformer 10 and a threshold voltage value. Because the charging sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com