Heat Sink Structure

a technology of heat sink and heat sink, which is applied in the direction of heat exchanger fastening, semiconductor devices for light sources, light and heating apparatus, etc., can solve the problems of reducing lighting efficiency, increasing heat produced by leds, and high amount of heat produced by electronic elements, so as to reduce weight and material cost, good heat dissipation effect, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

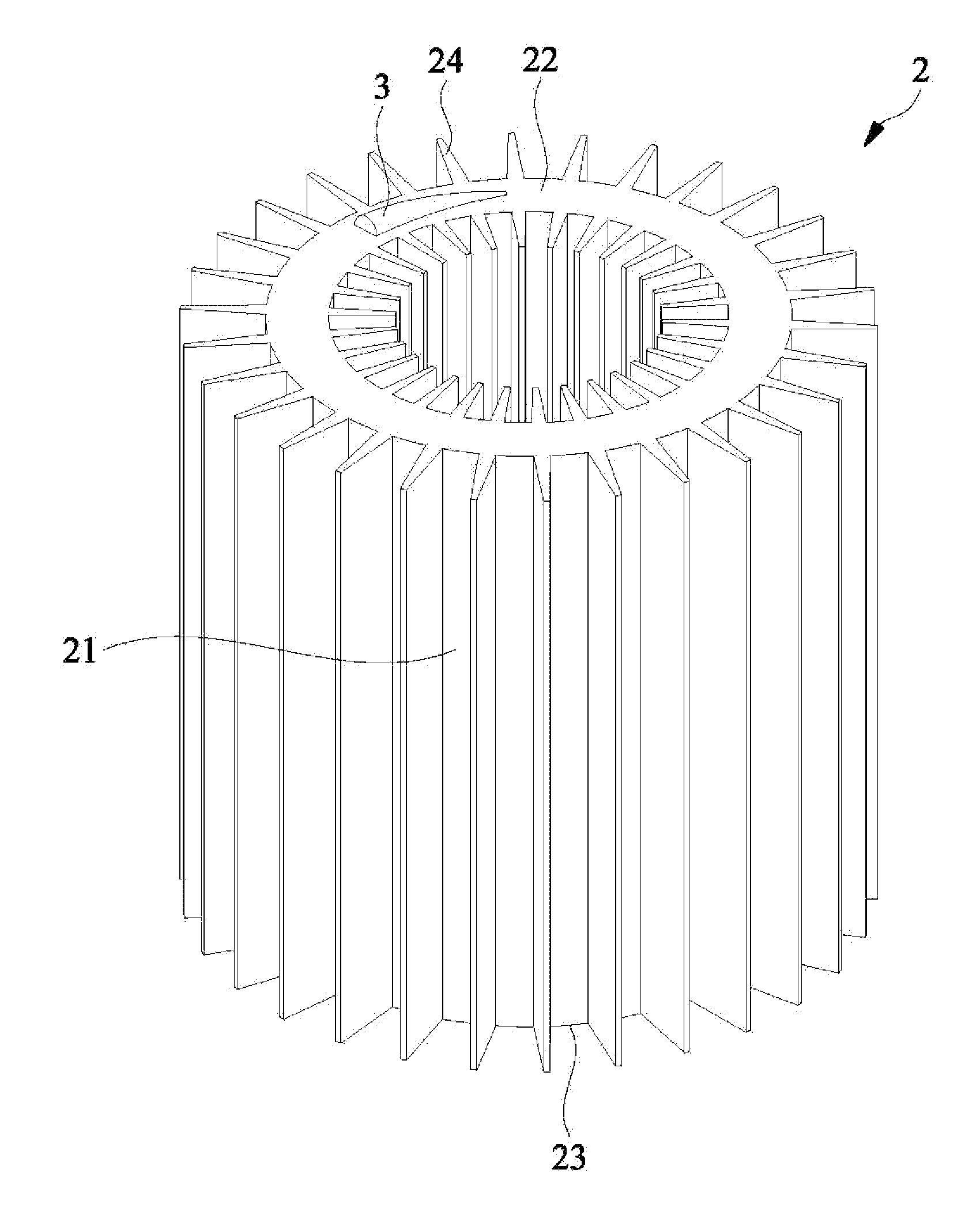

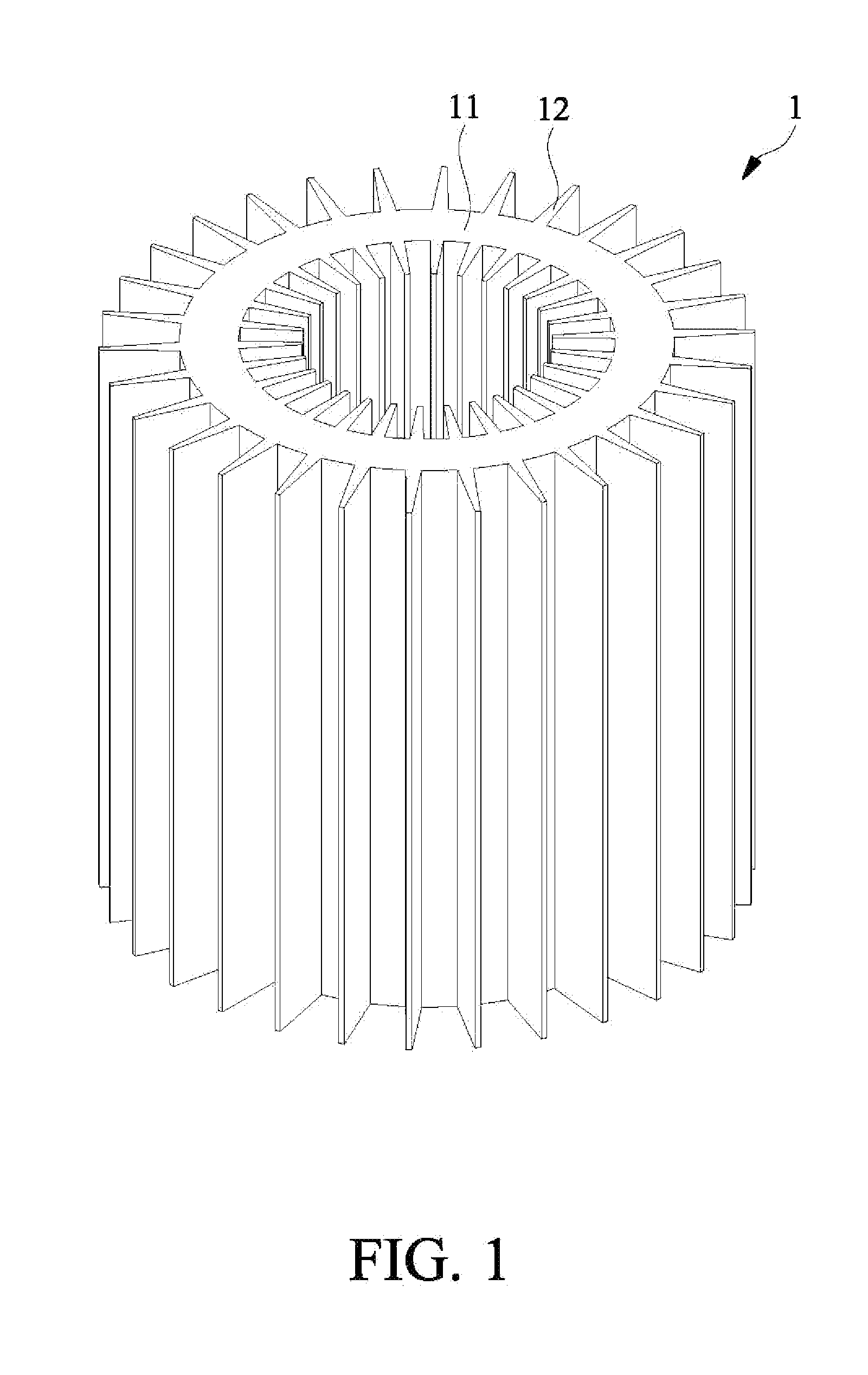

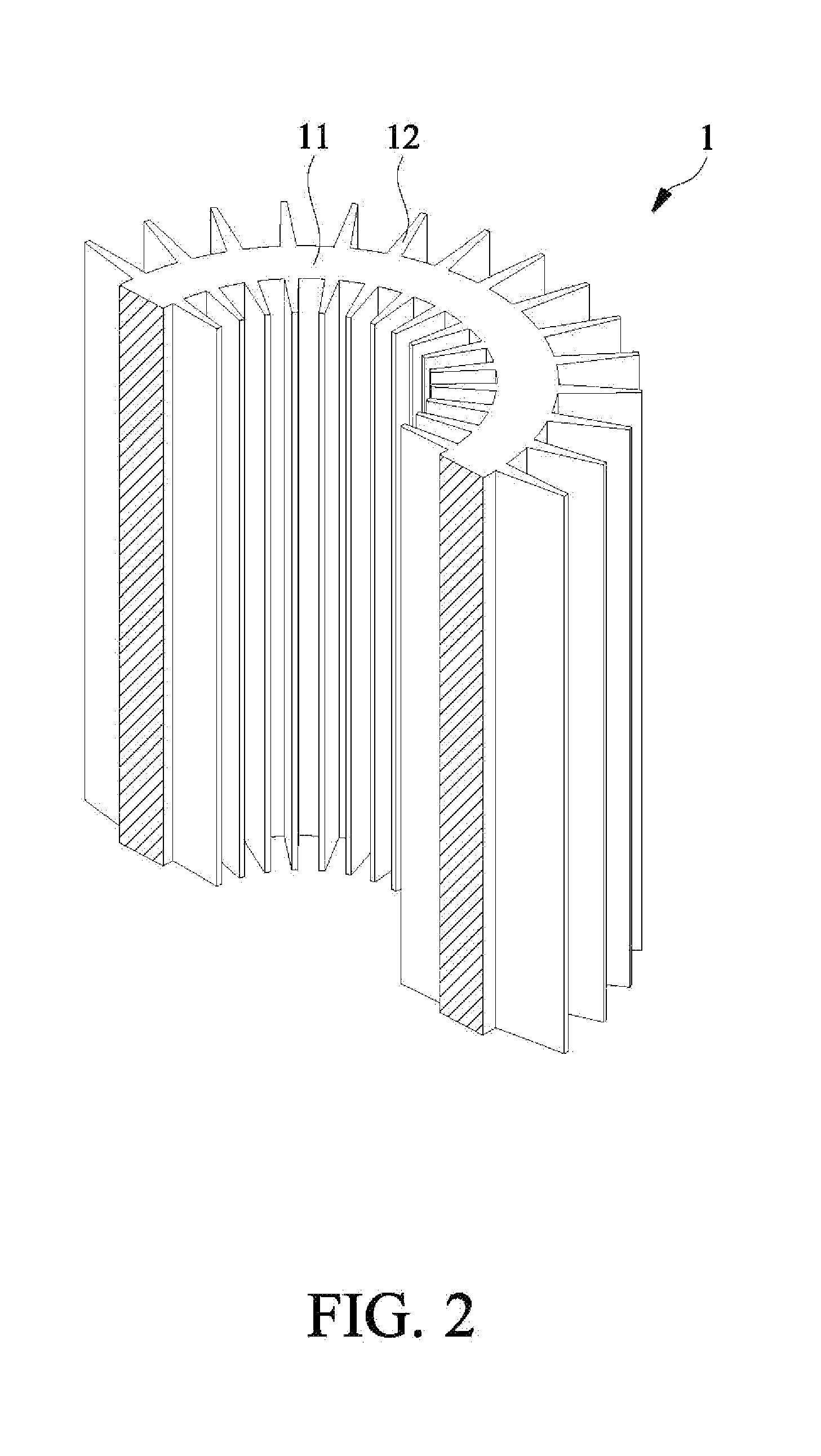

Please refer to FIGS. 3 and 4. A heat sink structure according to a preferred embodiment of the present invention includes a heat dissipating body 2 and a heat pipe 3. The heat dissipating body 2 is made of a plastic material through injection molding, and can be molded into various shapes depending on actual need. The plastic material for molding the heat dissipating body 2 is a heat-conducting material selected from the group consisting of Ethylon (UPE), polyoxymethylene (POM), polyethylene terephthalate (PETP), nylon, polypropylene (PP), polyethylene (PE), polyvinylidene fluoride (PVDF), Teflon (polytetrafluoroethylene or PTFE), polyvinyl chloride (PVC), Acrylonitrile Butadiene Styrene (ABS), tempered glass, polyether polyols (PES), acrylic (polymethylmethacrylate or PMMA), poly(ether-ether-ketone) (PEEK), and poly(amide-imide) (PAI).

In the illustrated embodiment of the present invention, the heat dissipating body 2 is injection molded into a hollow cylinder including a main body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com