Motor vehicle behind-glass adhesive label

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

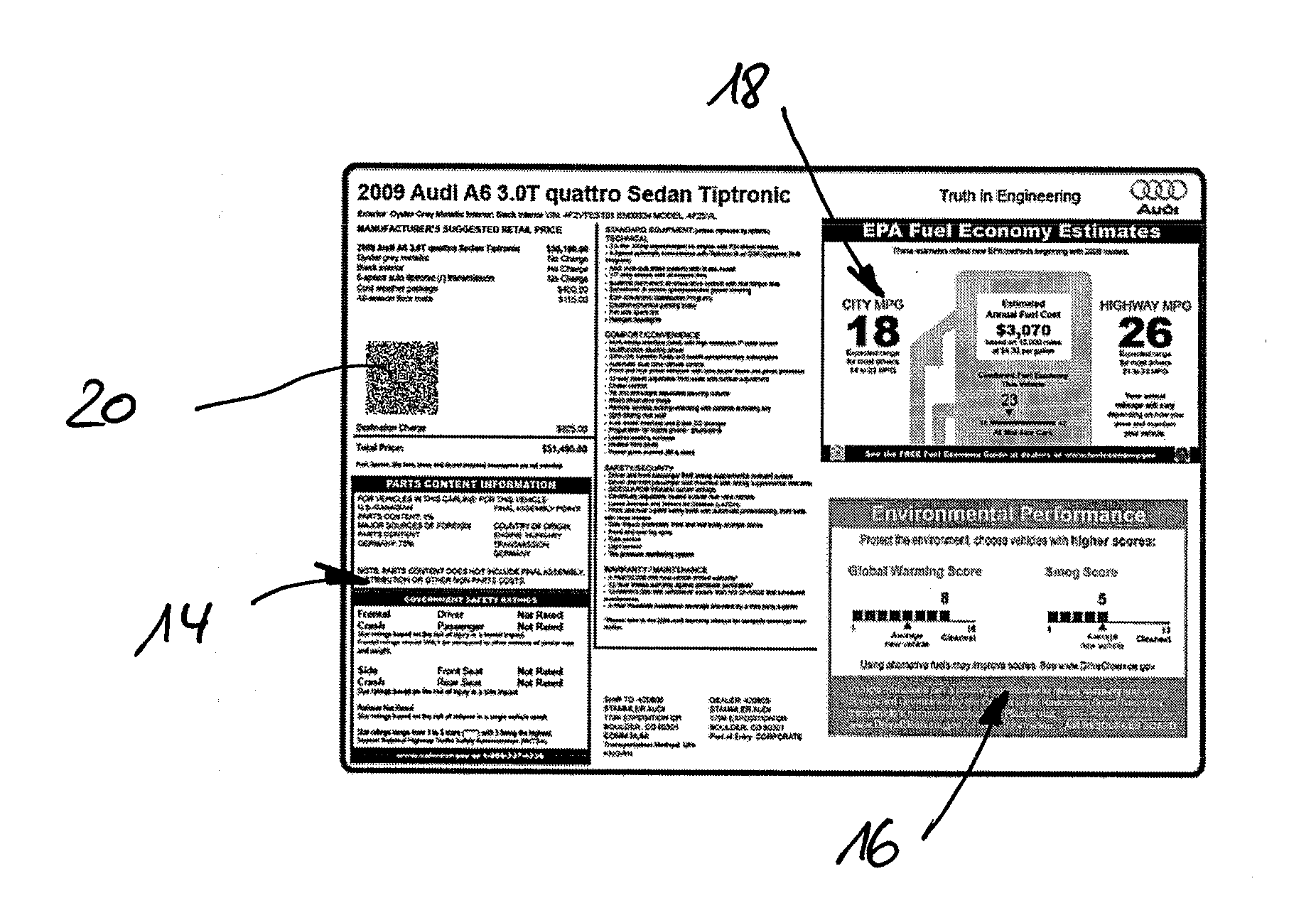

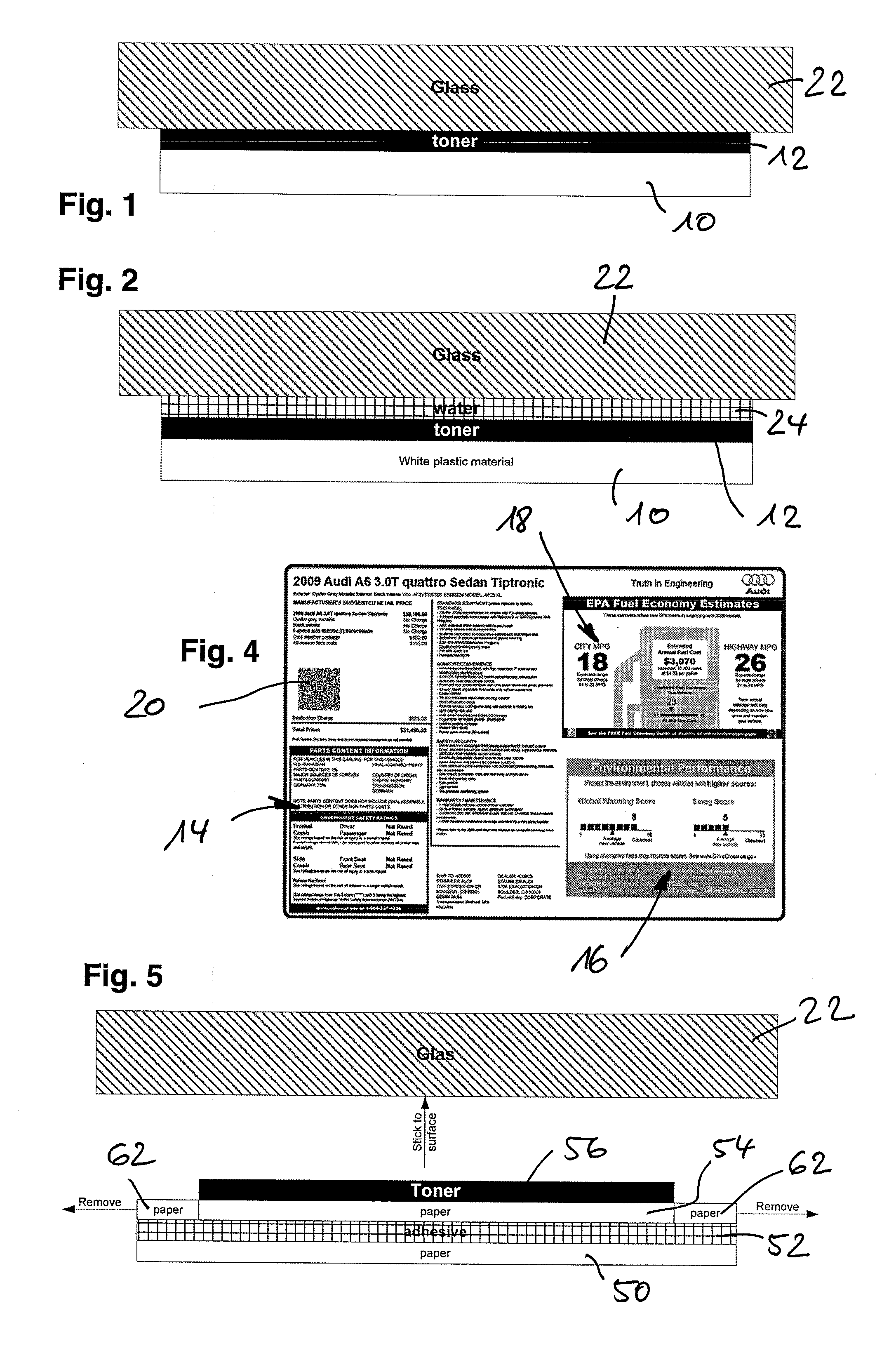

[0029]FIG. 1 clarifies the structural principles of a first example of embodiment (best mode) of the present invention. In the simplest example of embodiment a carrier layer implemented from a solid white-coloured polypropylene film 10 of a thickness of 76 μm has single-sided printing (“toner”) 12, which has a multiplicity of items of information for purposes of implementing the print image of a so-called Monroney adhesive label (FIG. 4); these include vehicle-specific information according to information block 14, environmental sustainability items of information according to information block 16, and fuel consumption items of information according to information block 18, as they are generated in the representation of FIG. 4 in the print image. In addition the print image contains a code region 20, as included in FIG. 4 as a two-dimensional barcode.

[0030]This print image is applied by means of a conventional laser printer or inkjet printer onto the film 10, wherein for this purpos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com