Method of driving a well pump

a well pump and well pump technology, applied in the direction of pumps, mechanical equipment, fluid removal, etc., can solve the problems of high capital cost of pump jack, rod string and insert pump, and the inability to maintain the pumping system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

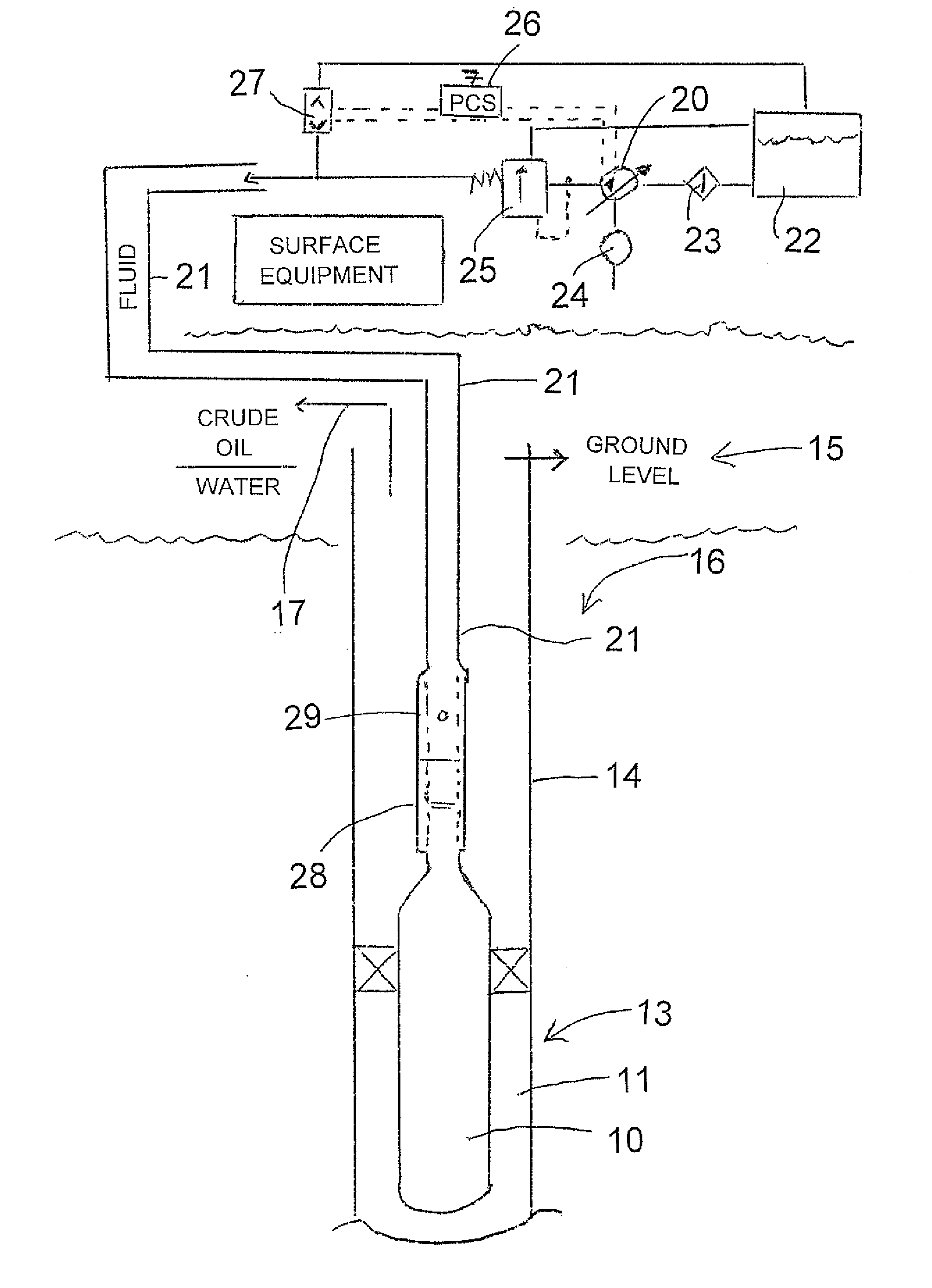

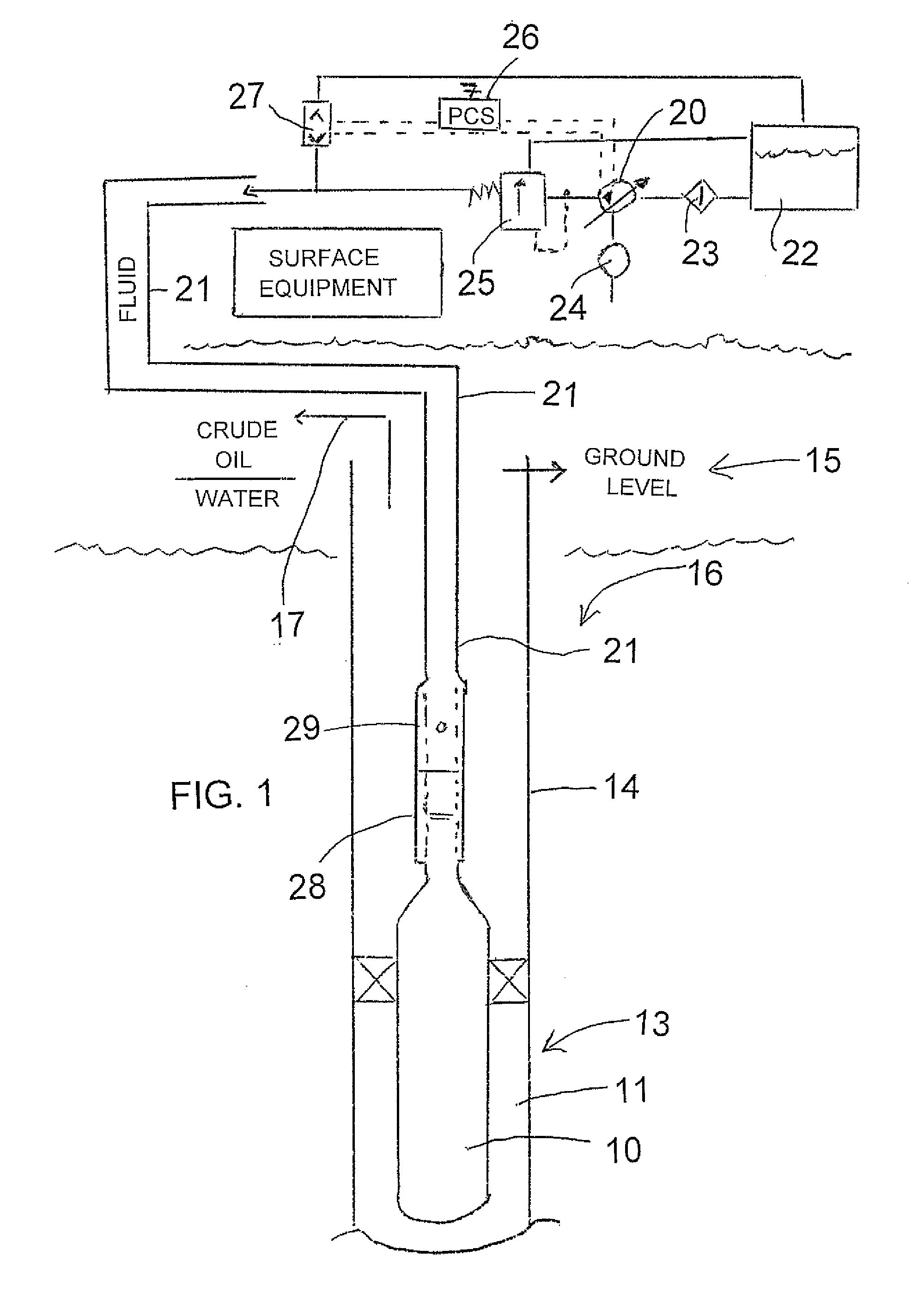

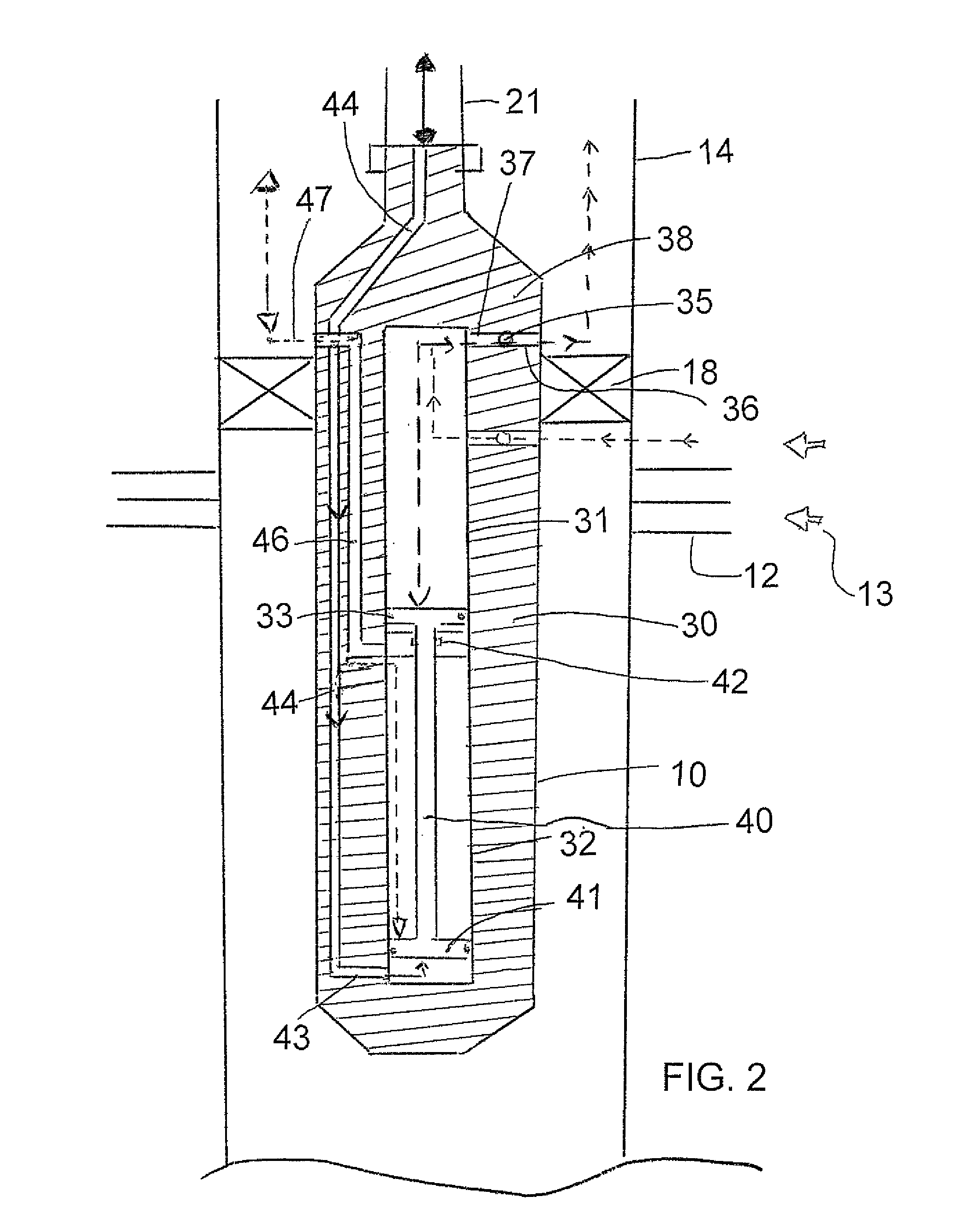

[0070]The system illustrated comprises a down hole reciprocating piston pump 10 which is mounted in a well bore 11 at a production location 12 where production liquid 13 enters into the pump 10 for pumping to the surface through a well casing 14. At the surface 15 above the ground 16 is provided a liquid recovery system 17 of a conventional nature for receiving the pumped liquid for transportation or storage as required using conventional systems.

[0071]The pump is mounted within the well casing 14 by a packing system 18 which locates the pump within the well casing and also divides well casing into a production zone below the packing and into a transportation zone above the packing. Thus, as is conventional in such pumps, the liquid is transferred by the pump from the location below the packing into the well casing so that the production liquid is carried up the well casing by the addition of further liquid into the well casing by the pumping action.

[0072]In the surface equipment as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com