Patterning Method for Carbon-Based Substrate

a technology of carbon-based substrates and substrates, which is applied in the direction of decorative surface effects, nanotechnology, material nanotechnology, etc., can solve the problems of difficult reduction of the manufacturing cost of carbon-based substrates, complex and time-consuming manufacturing process, and inability to widely use carbon-based substrates in various electronic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011]The invention is exemplified by an embodiment below. However, the embodiment is for exemplification only, not for limiting the scope of protection of the invention. Besides, secondary elements are omitted in the embodiment for highlighting the technical features of the invention.

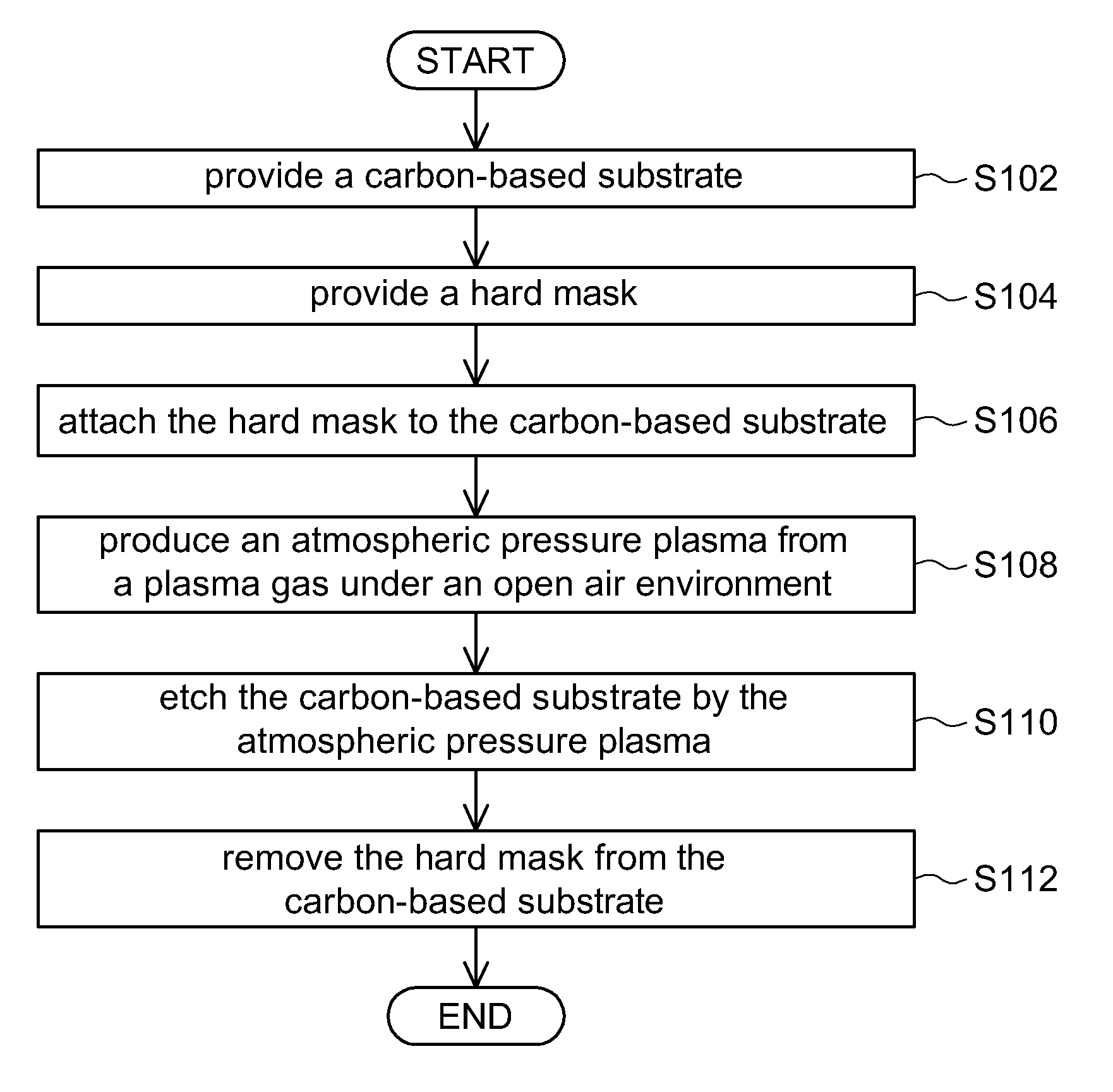

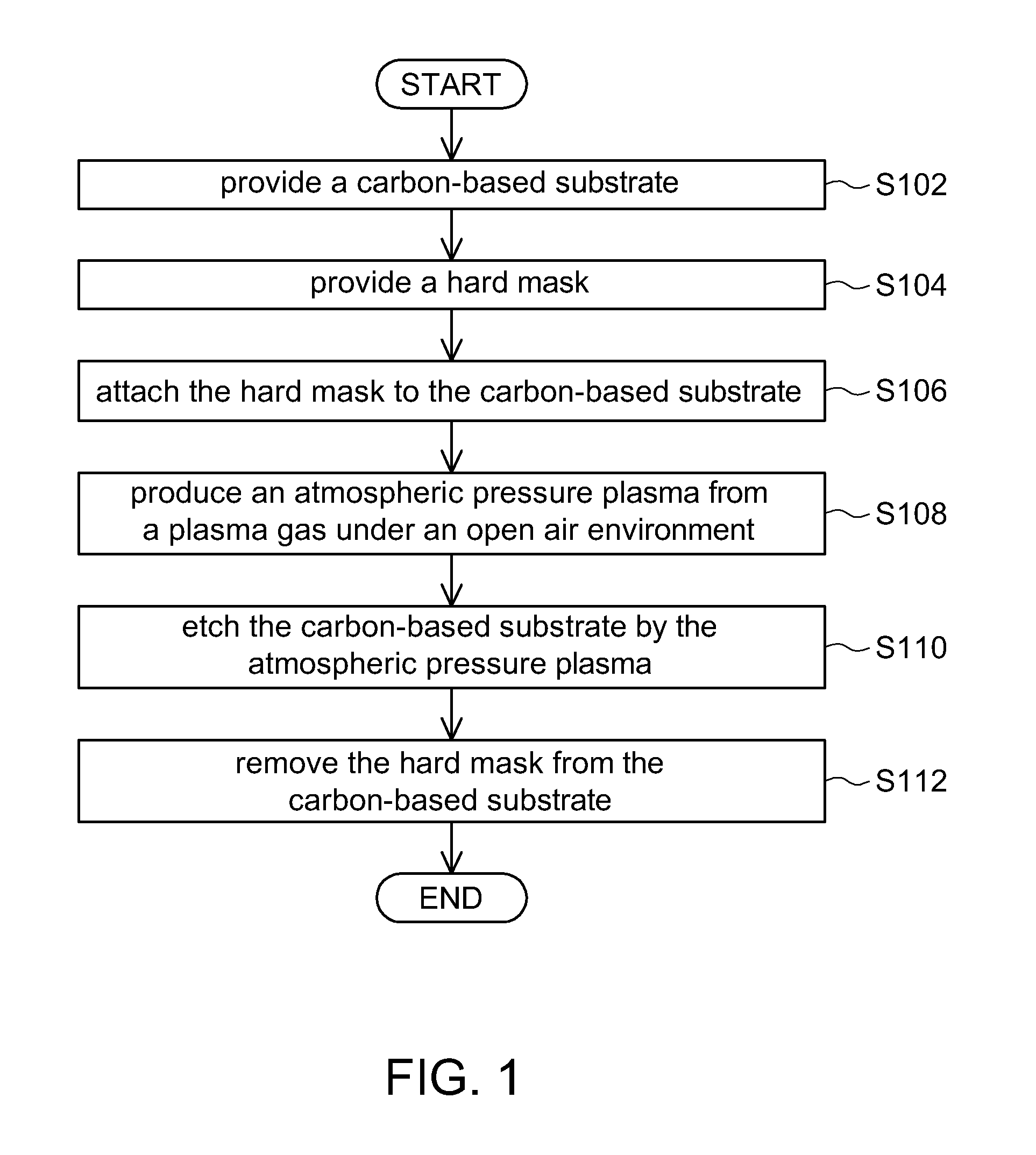

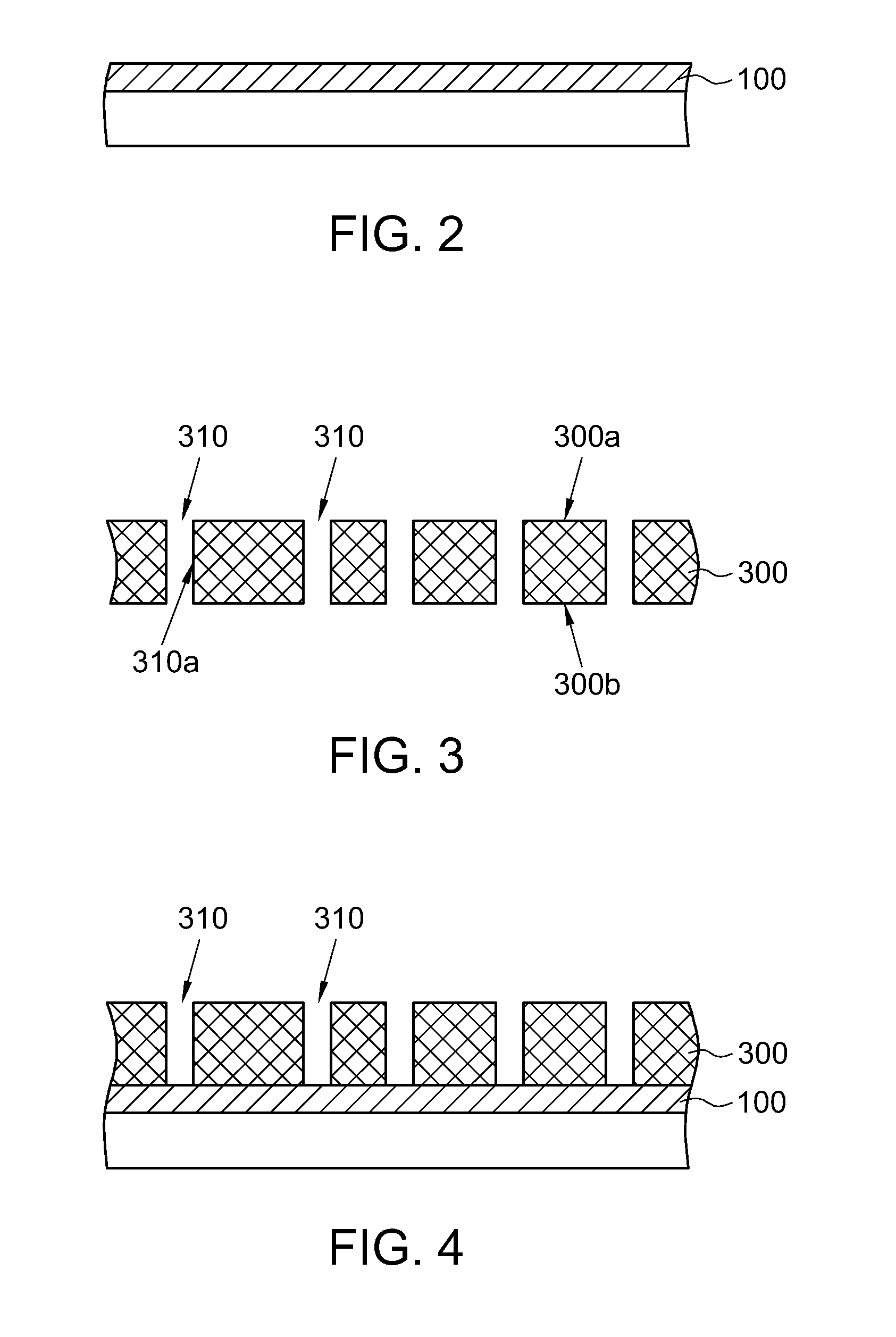

[0012]Referring to FIG. 1 and FIGS. 2-7. FIG. 1 shows a flowchart of a patterning method for a carbon-based substrate 100. FIGS. 2-7 show the respective steps of FIG. 1.

[0013]Firstly, the method begins at step S102, as indicated in FIG. 2, a carbon-based substrate 100 is provided. In the present embodiment of the invention, the carbon-based substrate 100 is exemplified by a transparent carbon nanostructure-based thin film like carbon nanotube or nano-graphite. The optical properties of the transparent carbon nanostructure-based thin film are similar to that of the indium tin oxide film (ITO film). The transparent carbon nanostructure-based thin film having high electron conductivity can be used to form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittance | aaaaa | aaaaa |

| atmospheric pressure | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com