Adiabatic plug flow reactors and processes incorporating the same

a plug flow reactor and reactor technology, applied in chemical/physical/physical-chemical processes, halogenated hydrocarbon preparations, organic chemistry, etc., can solve the problems of additional difficulties in temperature control and heat transfer characteristics, reduce the quality of plug flow, and achieve optimized mixing , the effect of facilitating the reduction of backmixing and/or recirculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

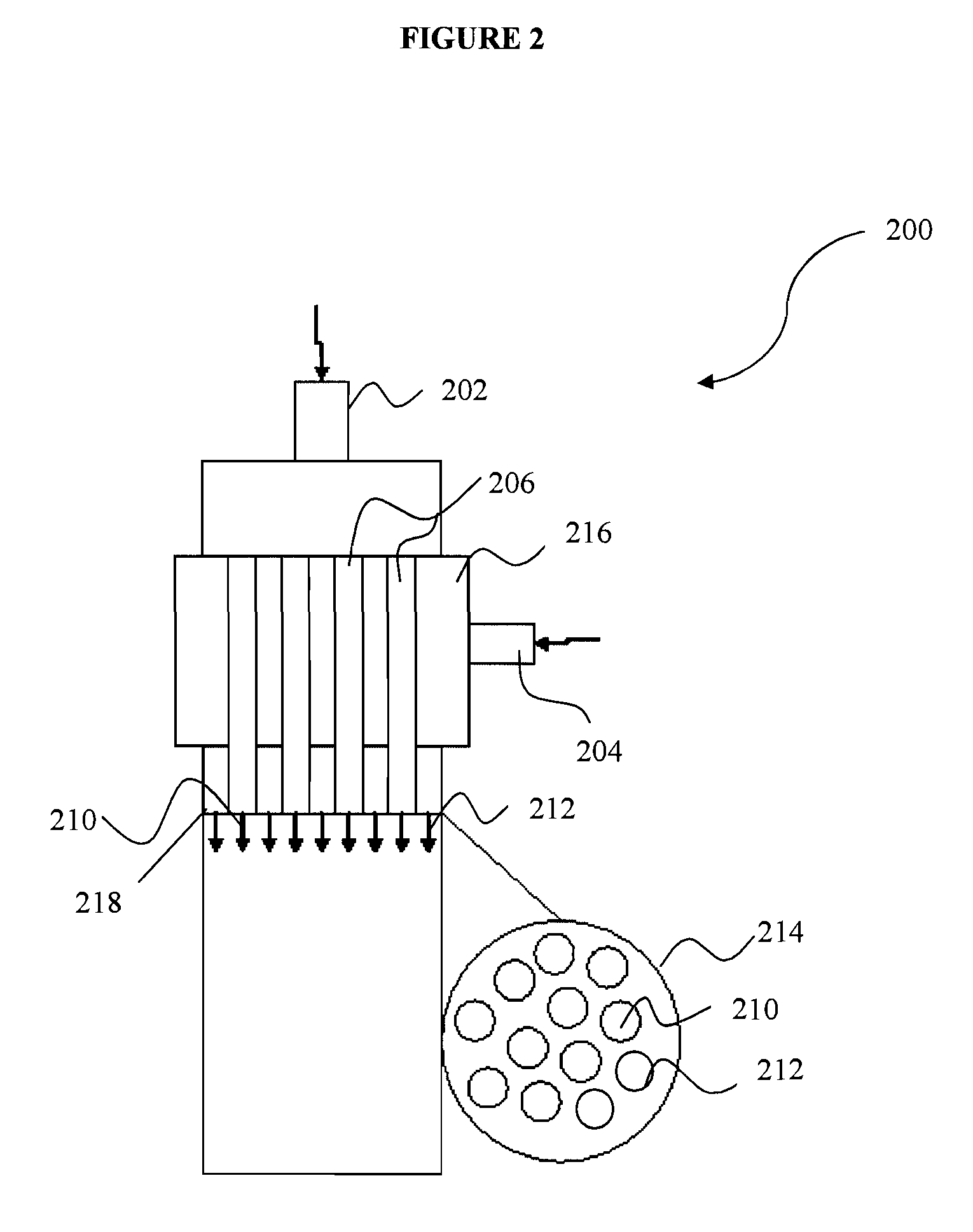

[0058]For this example, perchloroethylene and methyl chloride are reacted in the presence of the initiator carbon tetrachloride to provide 1,1,2,3 -tetrachloropropene in a reactor comprising both a design that allows the production rate to be adjusted by controlling the temperature of the reactor effluent and a design that facilitates reduced backmixing prior to entry into the adiabatic plug flow reactor. More particularly, the reactor comprises a mixer having the design shown in FIG. 2, and, separate evaporators for the perchloroethylene and methyl chloride.

[0059]Perchloroethylene will be introduced into a 6 foot internal diameter tubular reactor at a temperature of about 325° C. and a feed rate of about 2.65 MM# / day. Methyl chloride will be fed at a rate of 2.01 MM# / day and a temperature of 430° C., while carbon tetrachloride will be provided to the reactor at a feed rate of 0.25 MM# / day and at a temperature of 325° C. Because the perchloroethylene is set at a lower temperature th...

example 3

[0060]For this example, perchloroethylene and methyl chloride are reacted in the presence of the initiator carbon tetrachloride to provide 1,1,2,3 -tetrachloropropene in a reactor comprising both a design that allows the production rate to be adjusted by controlling the temperature of the reactor effluent and a design that facilitates reduced backmixing and / or recirculation prior to entry into the adiabatic plug flow reactor. More particularly, the reactor utilized comprises a mixer having the design shown in FIG. 2, and, separate evaporators for the perchloroethylene / carbon tetrachloride and methyl chloride.

[0061]Methyl chloride, perchloroethylene and carbon tetrachloride were fed to a 2″ ID Inconel 600 reactor at the rate of 3500-4500 SCCM, 1400-17000 SCCM, and 700-980 SCCM respectively to achieve about 30-40 seconds residence time at 260 psig.

[0062]The reactor is equipped with the mixer shown in FIG. 2. The methyl chloride stream was preheated to from about 340° C. to about 370° ...

example 4

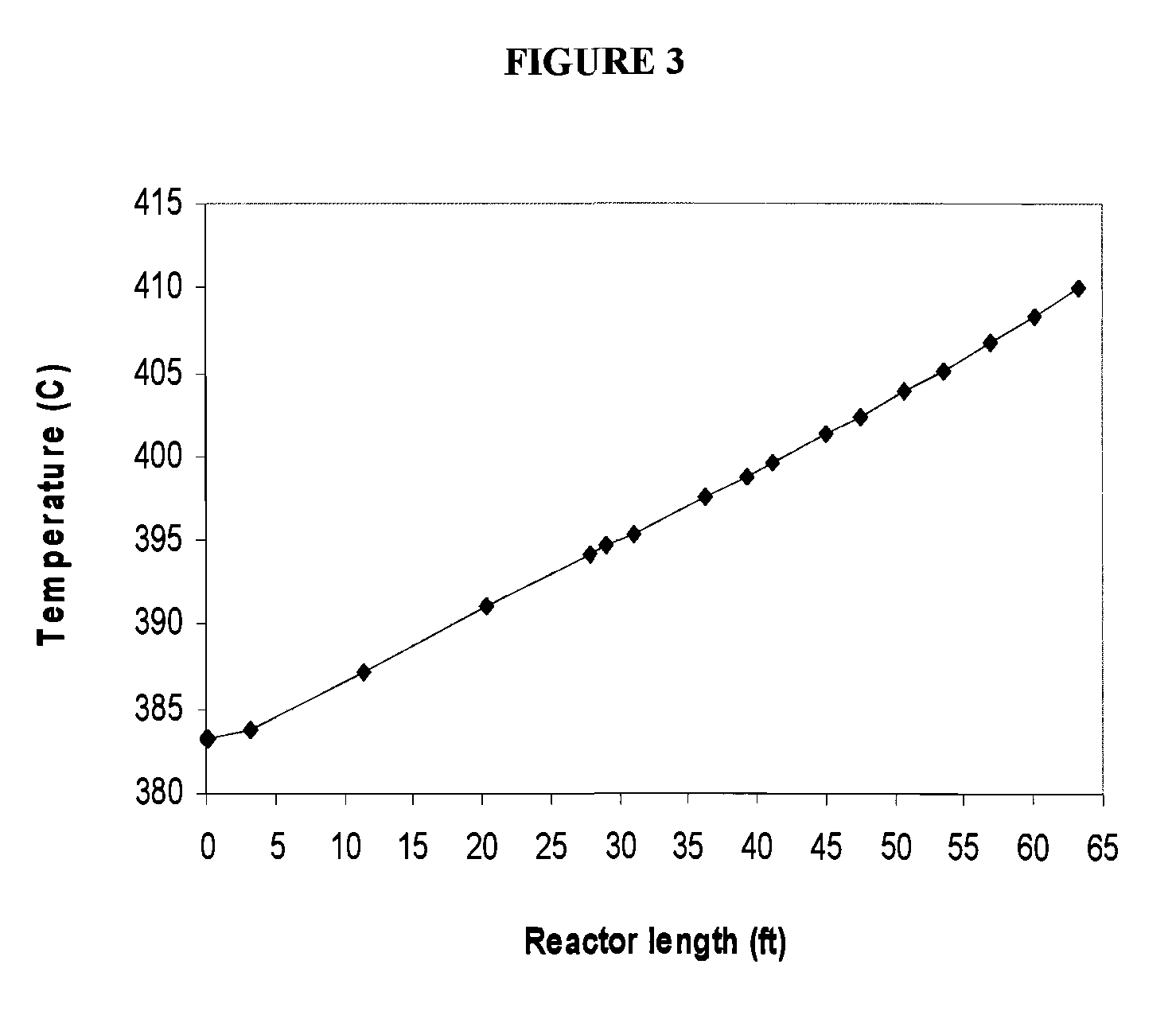

[0063]Chlorinated and / or fluorinated propenes having the formula CH2-c-gClcFg═CH1-d-hCldFh—CH3-e-fCleFf wherein c is 0-2, d is 0-1, e is 0-3, f is 0-3, and g is 0-2 while c+g≦2, d+h≦1, and e+f≦3 are prepared using a reactor having a design that minimizes heat transfer to and / or from the reactor, and in accordance with Examples 2 and 3. With overall reactor volume similar to that described in Example 2, Table 1 shows that at least 10 cm insulation with effective thermal conductivity of 0.05 W / M / ° C. is expected to maintain reagent conversion close to 10% in a reactor with 6 ft ID.

[0064]Table 1 also shows that removing the insulation, leaving the reactor metal wall of Inconel results in an effective thermal conductivity of 20 W / M / ° C. and this is expected to drop the conversion or productivity by more than 50% if the same reactor length is used. Reducing the reactor diameter to 1 ft keeping the same reactor volume and insulation thickness the same results in about 10% drop in reactor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com