Method of and apparatus for cleaning fouling in heat exchangers, waste-heat boilers and combustion chambers

a technology of waste heat boilers and cleaning methods, applied in the direction of steam boiler components, combustion process, combustion treatment, etc., can solve the problems of reducing the efficiency of heat exchangers, waste heat boilers, or combustion chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

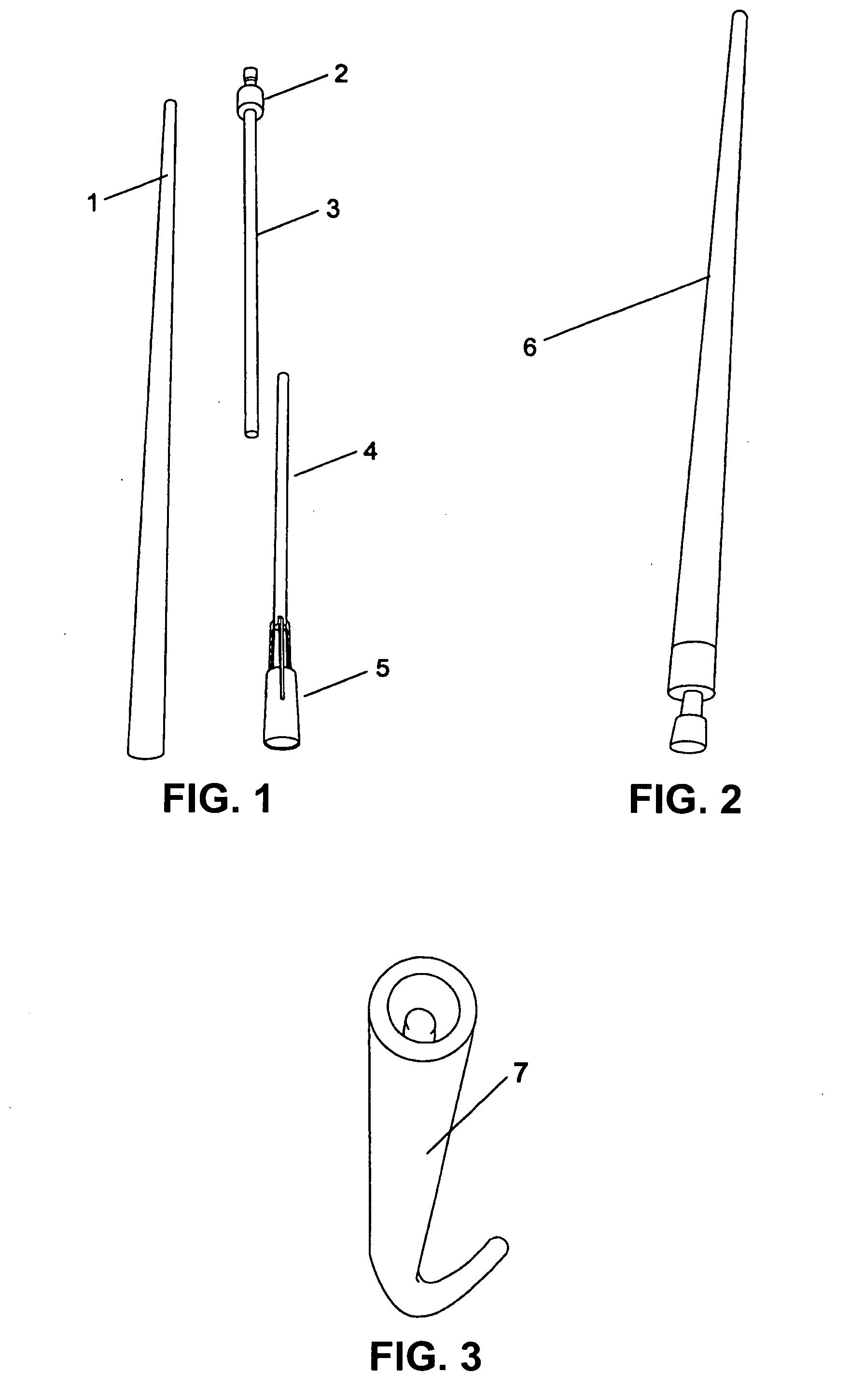

[0007]FIG. 1 shows a cardboard tube 1, which accommodates a spark plug 2. The tube is provided at one end with a closure means, and a gas filling connection 5 is provided at the other end.

[0008]FIG. 2 shows an assembled embodiment 6 of the device.

[0009]Depending on the desired use, the tube can be made of any length. For example, in the embodiment depicted in FIG. 2, the tube is of a relatively small diameter (e.g., 3 cm to 15 cm), so that the tube may be introduced into a heat exchanger line containing gases within a combustion chamber.

[0010]After triggering of a blasting action that may destroy the entire cardboard tube, certain parts, such as a spark plug, threaded rod, closure means, and so forth, can be further used again.

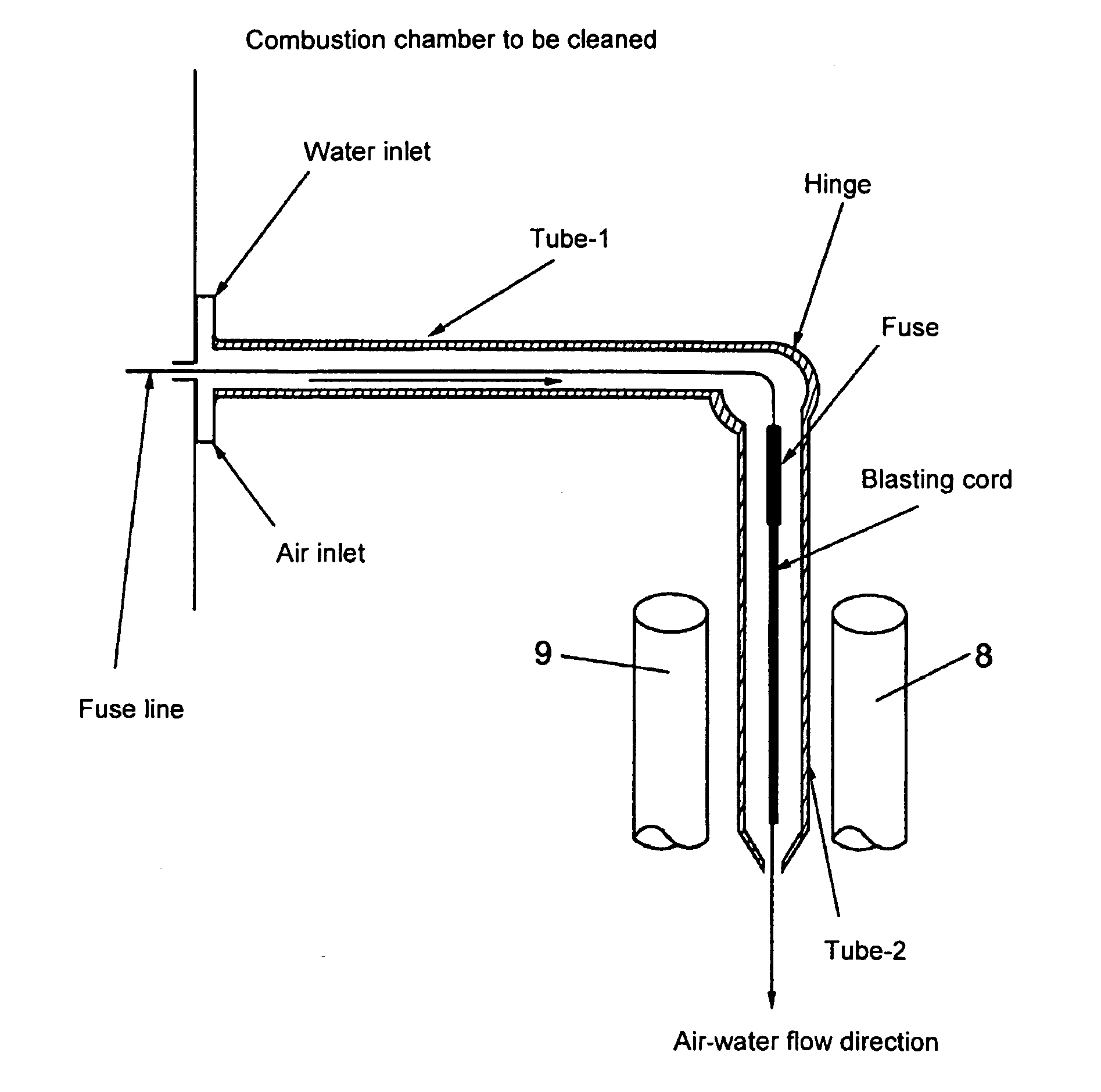

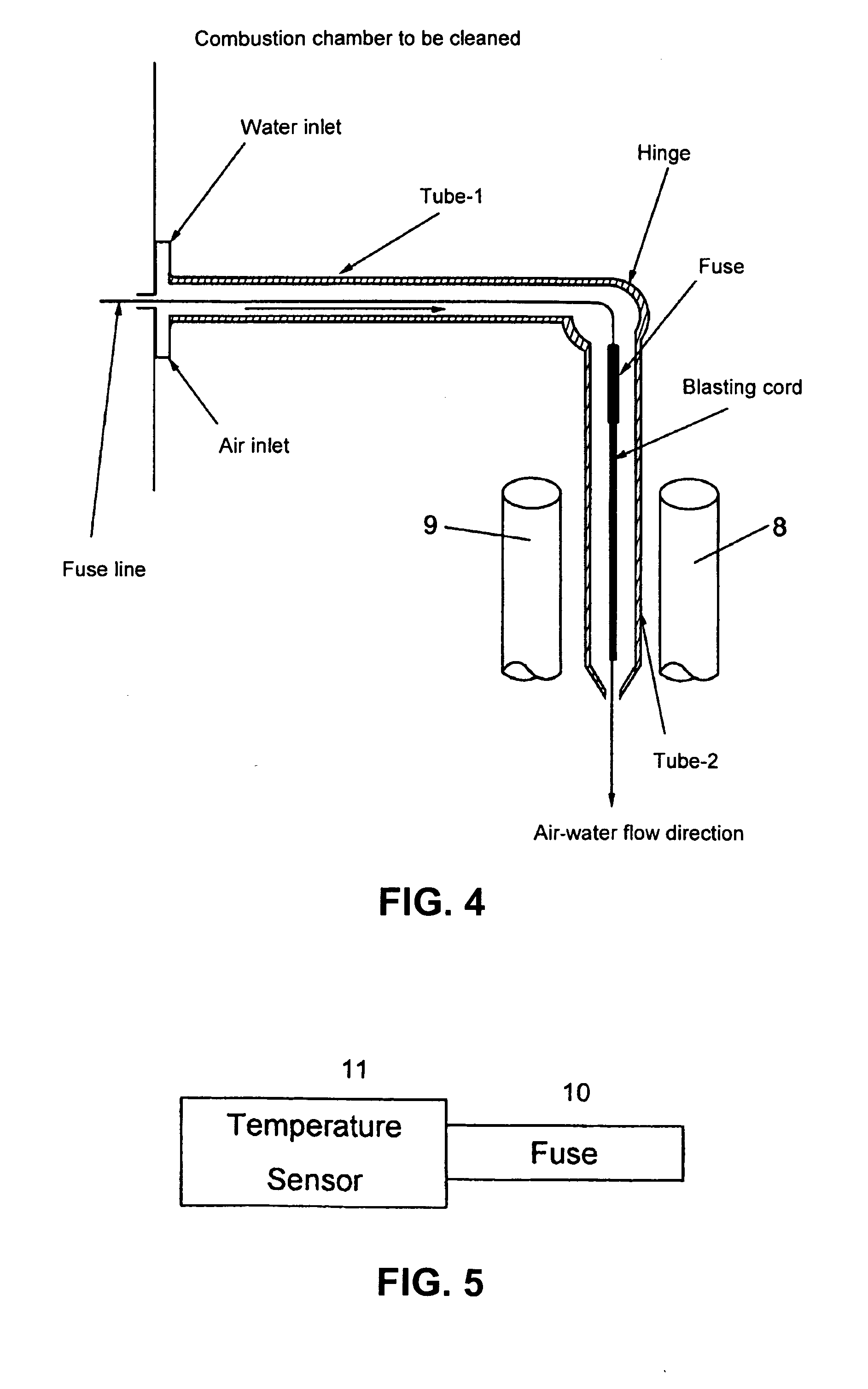

[0011]FIG. 3 shows an alternative embodiment, wherein a first tube, which is connected to a second tube via a hinge 7, is fitted into a combustion chamber. Due to the hinge 7, the angle of the second tube (blasting tube) can be precisely adjusted according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com