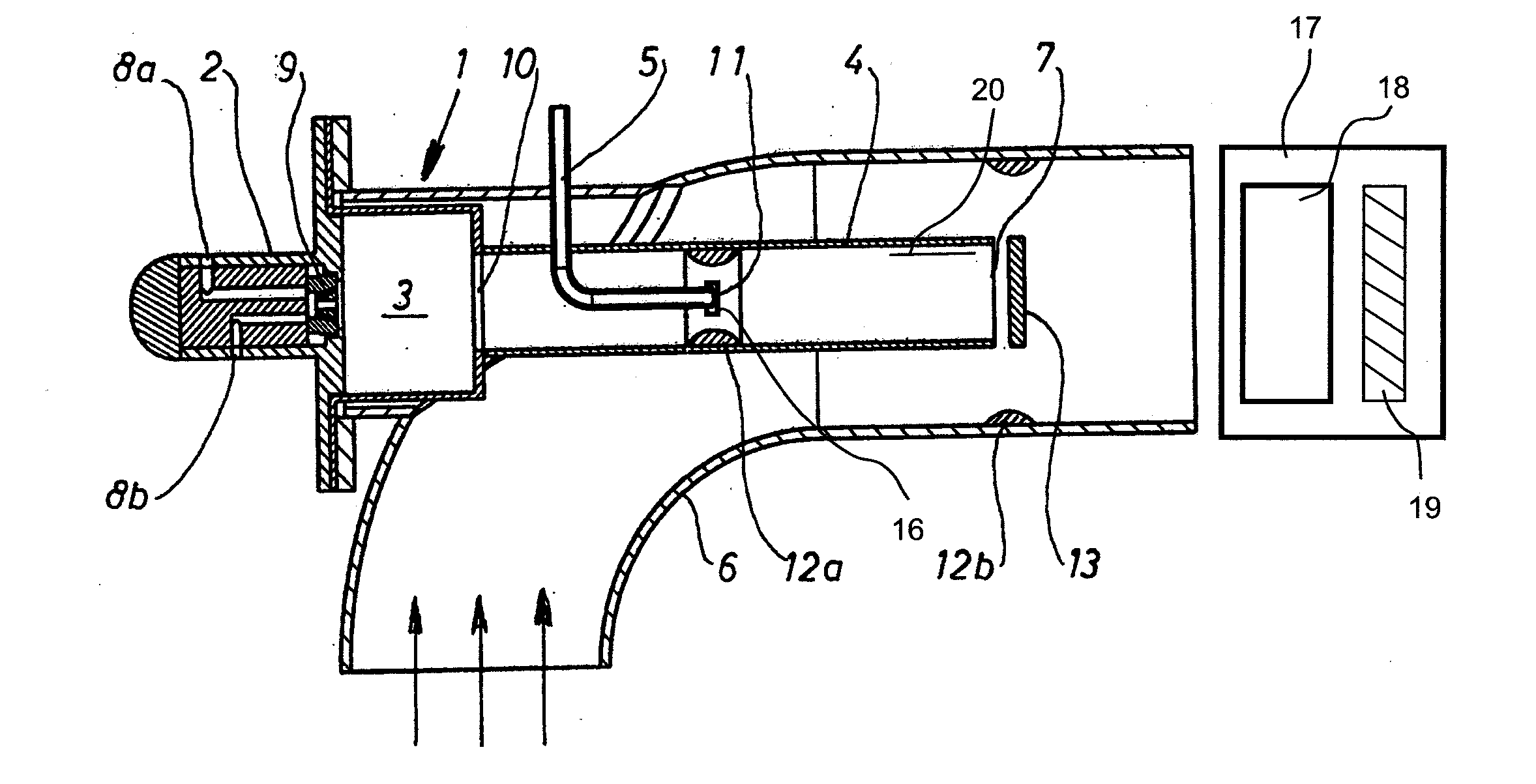

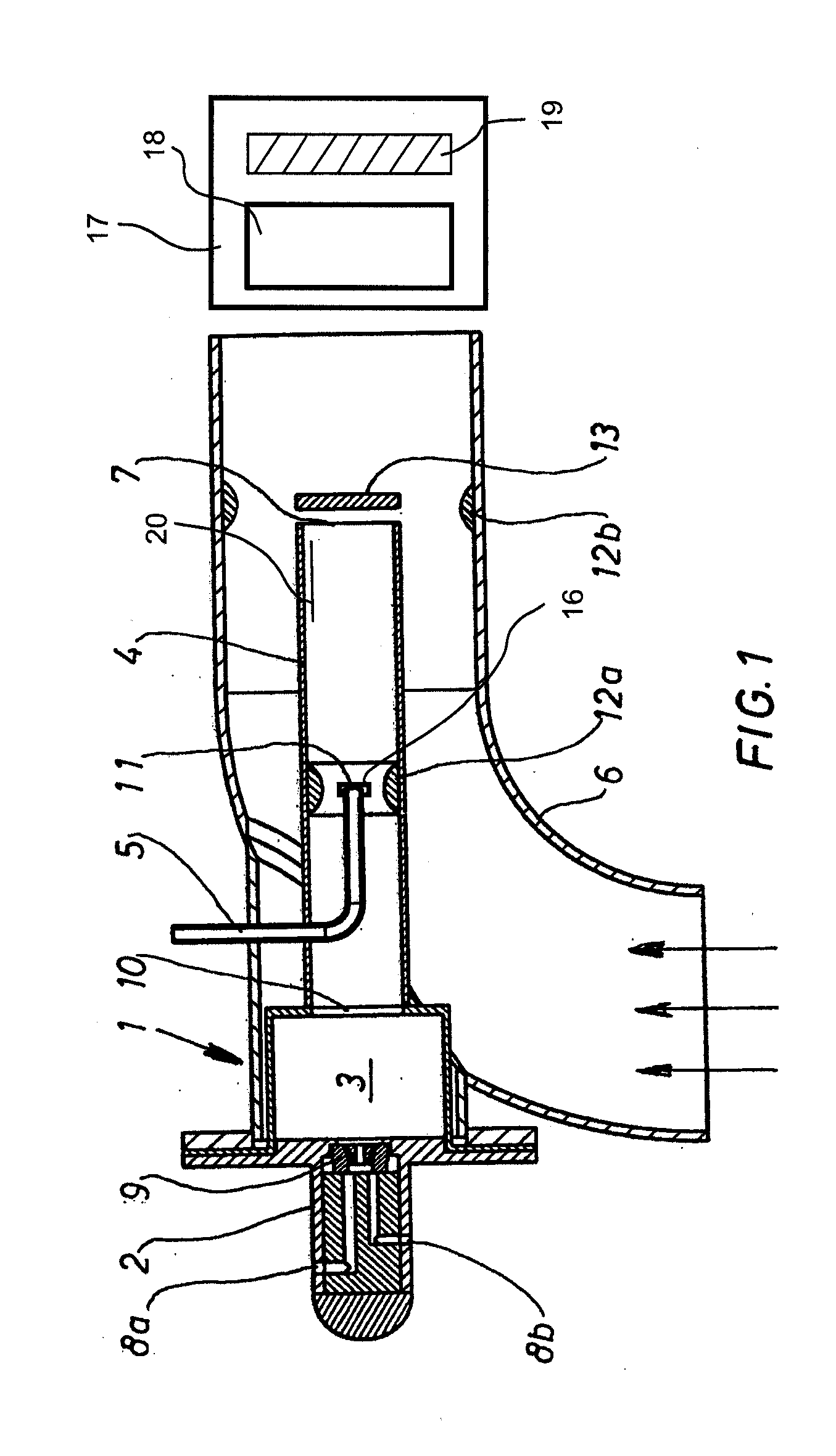

[0010]In a further embodiment, a venturi device is arranged in the exhaust duct near an opening of the

introduction device. This effects a

rapid mixing of the partial streams of exhaust gas and vaporizable liquid encountering each other.

[0013]In a further embodiment, the exhaust duct projects into the exhaust pipe with at least one port thereof. In this way, a good mixing of the converging streams of gas is ensured. For this purpose, the exhaust duct is preferably inserted concentrically into the exhaust pipe in such a manner that the port of the exhaust duct is arranged in the direction of the process exhaust gas

stream, that is, for example, the

internal combustion engine exhaust

stream. This configuration achieves an increase in the velocity of flow of the process exhaust gas, which leads to a

rapid mixing of the gas mixture, the same including the burner exhaust and the vapor (vaporized liquid), and the process exhaust. In this way, ignition of the gas mixture can be prevented if the process exhaust gas contains

oxygen.

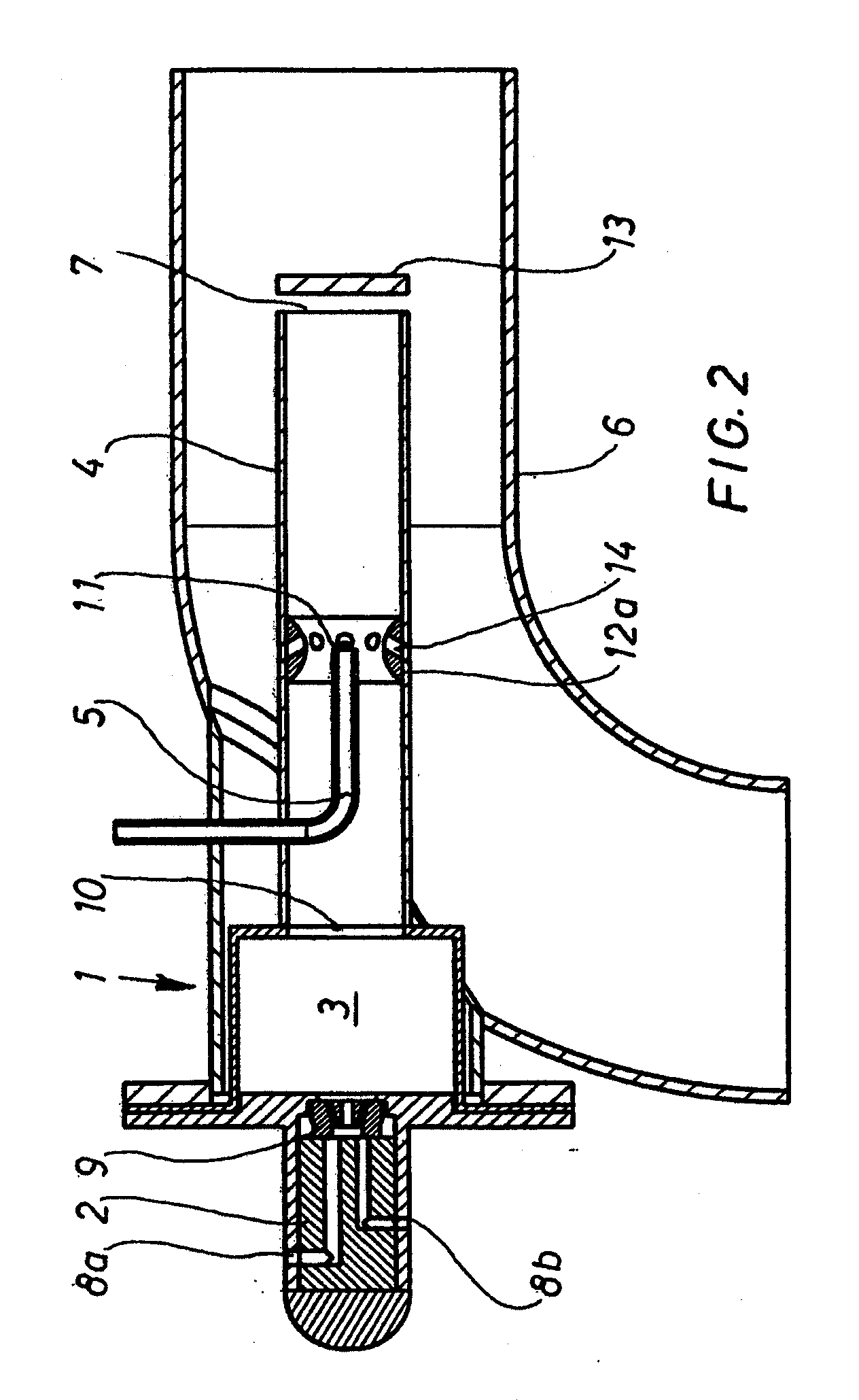

[0014]In order to further inhibit chemical reactions in the region of the inlet, appropriate auxiliary means can be provided which facilitate the same. Possible examples of such auxiliary means are, for example, a plate or a cone which is arranged before the port of the exhaust duct, wherein the tip of the cone is oriented facing the port of the exhaust duct. This configuration also provides a narrowing of the flow area in the region of the port, in addition or as an alternative to a further increase in the flow velocity, said narrowing being provided in the form of a venturi device or a venturi

nozzle, for example. In other words, the configuration should quench a possible reaction between the process exhaust gas and the burner exhaust, the latter being prepared with vaporizable liquid.

[0016]In this way, the burner exhaust is cooled down in a controlled manner (where the feed is configured upstream from the opening of the feed inlet device in the direction of flow), and in such a manner that sufficient energy is provided for the purpose of vaporizing the vaporizable liquid, although the

combustion of the same is prevented (if the vaporizable liquid is fuel). However, the feed can also be configured in the region of the opening, or downstream from the opening in the direction of flow. A

chemical reaction between the vaporizable liquid and the burner exhaust and / or the process exhaust gas can be either facilitated or inhibited depending on requirements by means of appropriately selecting the described auxiliary means. Particularly by means of influencing the temperature in the region of the feed inlet device, it is possible to generate substances in a targeted manner by means of reactions between the vaporizable liquid and the burner exhaust, wherein said substances facilitate desired reactions in the downstream catalytic

converters.

[0018]The constructive configurations described above are utilized in a reasonable manner for the purpose of implementing the further embodiment of the operating method according to the invention described below. As such, the burner is operated in a

lambda range from 0.75 to 1.75, preferably at a

lambda of 1. In addition, the burner is designed in such a manner that it can be operated in a power range up to 20 kW, preferably up to 15 kW, and most preferably up to 5 kW. It is one aim of the invention to operate the burner at the lower possible power, because particularly the air supply device required for the supply of (combustion-) air can then be designed with a relatively simple construction.

[0022]In an further embodiment of the method, a partial volume of the total volume of combustible fuel, the same being introduced as the vaporizable liquid and then vaporized, is oxidized within the exhaust duct and / or in the place where the same is brought together with the process exhaust, releasing heat. In this way, the total

thermal energy provision is increased, coincident with burner performance adjusted to a minimal setting, to such a degree that the startup of a

catalytic converter is ensured. In order to initiate the activity thereof, that is, in order to start a catalytic reaction of the introduced, vaporized fuel, an oxidative

catalytic converter must achieve a prespecified minimum temperature, for example 300° C. This temperature is achieved by means of the total sum of energy from the burner and the energy generated by the combusted partial volume.

Login to View More

Login to View More  Login to View More

Login to View More