Dc-dc converter circuit

a converter circuit and converter technology, applied in the direction of electric variable regulation, process and machine control, instruments, etc., can solve the problem of surge voltage applied to the rectification element when it is turned off, and achieve the effect of enhancing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

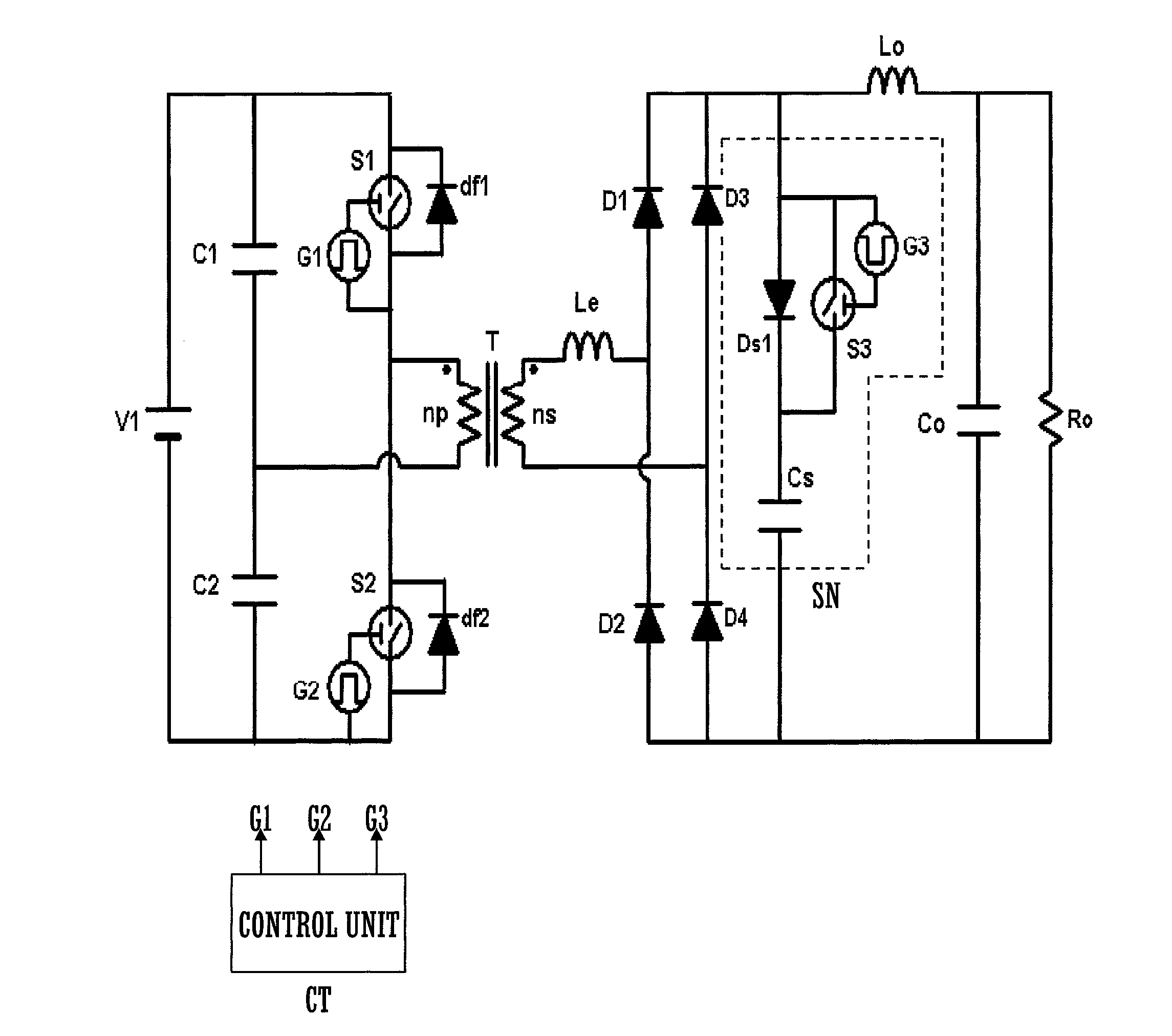

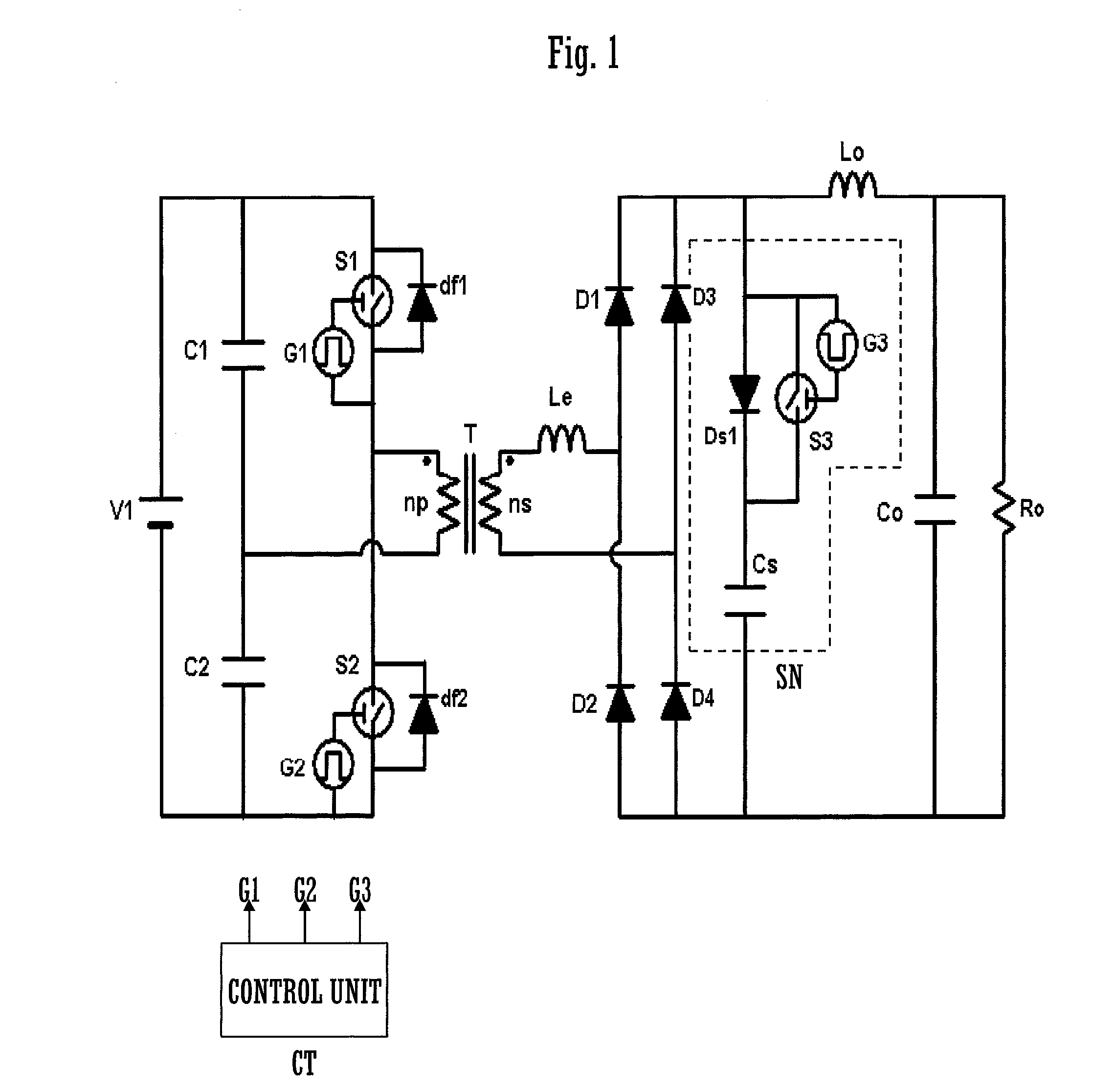

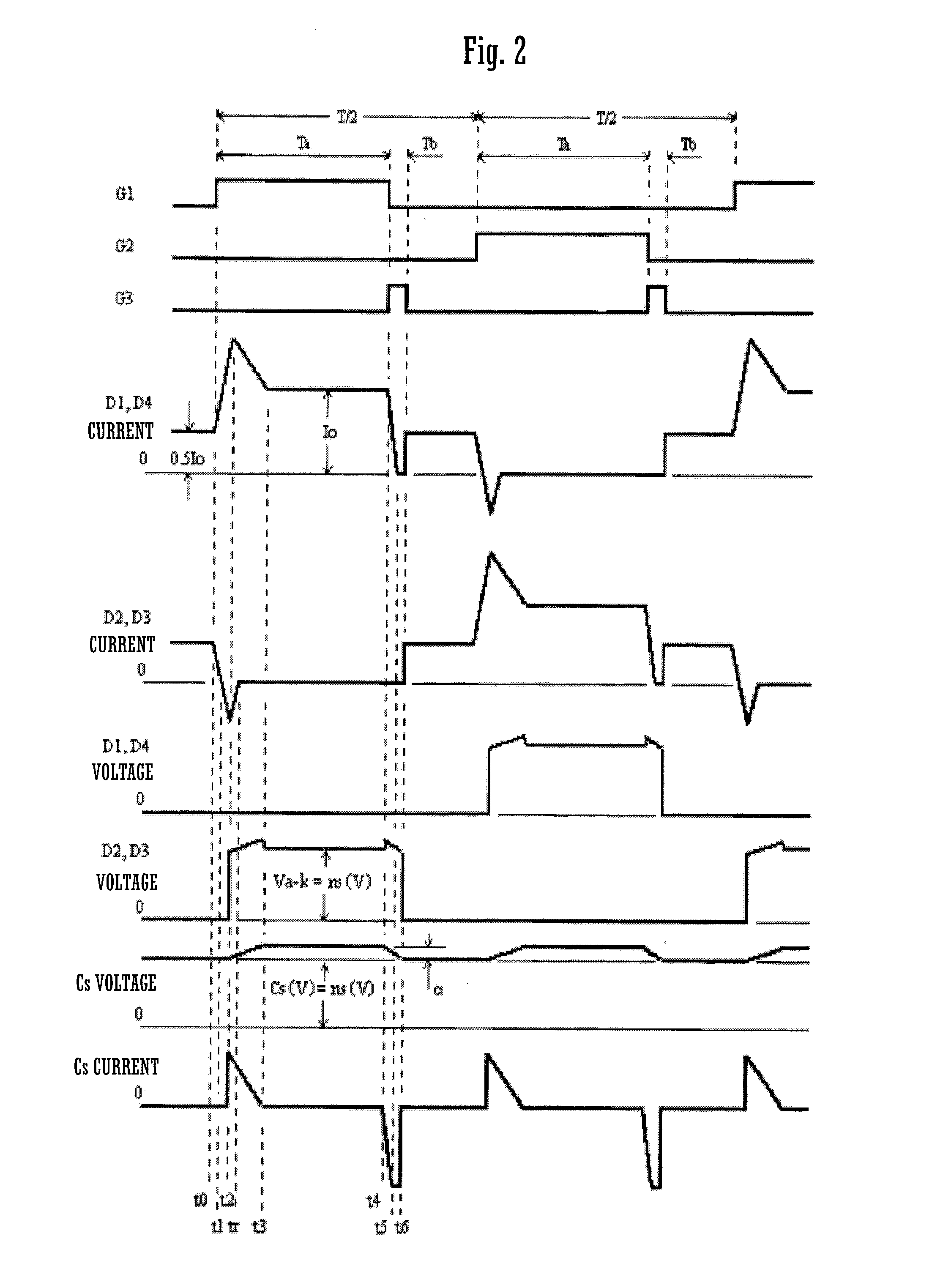

[0019]FIG. 1 is a circuit diagram of a DC-DC converter circuit which is an embodiment of the present invention.

[0020]A series circuit of a first capacitor C1 and a second capacitor C2, which constitutes a voltage source, is connected in parallel with a DC power supply V1, and primary side switching elements, in other words a first switching element S1 and a second switching element S2, are each connected in parallel to these capacitors C1 and C2. Each of these switching elements S1 and S2 is a semiconductor switching element, and may, for example, be an IGBT (insulation gate type bipolar transistor) or a MOS-FET. A primary winding np of a transformer T is connected between the point of connection between the capacitors C1 and C2 and the point of connection between the switching elements S1 and S2. Respective free wheel diodes (clamp diodes) df1 and df2 are connected in reverse parallel to the switching elements S1 and S2. Moreover a control unit CT is provided, which outputs respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com