Apparatus and method for treating etching solution

a technology of etching solution and apparatus, which is applied in the direction of reverse osmosis, membranes, and the nature of treatment water, can solve the problems of significant difficulty in concentration control, and achieve the effects of reducing the exchange frequency of etching solution, reducing the amount of acid used to neutralize a highly concentrated waste alkali solution, and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

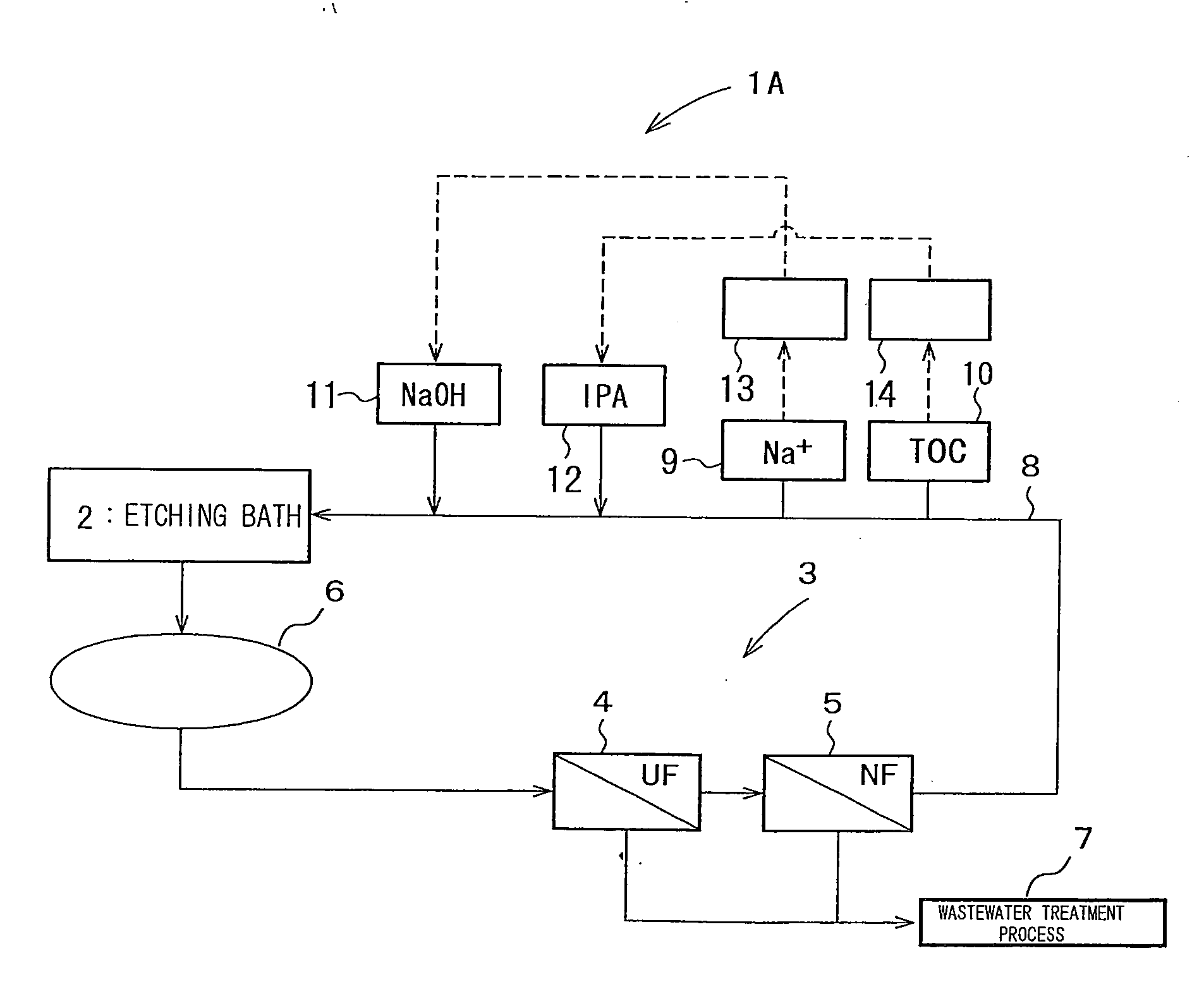

[0083]An apparatus shown in FIG. 1 was used as the apparatus for treating etching solution. The volume of the etching bath 2 was the same as that of COMPARATIVE EXAMPLE 1, and specifications and operation conditions of the UF membrane module 4 and NF membrane module 5 were as stated below.

[0084]UF Membrane Module 4: Nitto Denko Corp., “NTU-3306-K6R”

[0085]NF Membrane Module 5: NADIR Corp. (Germany), “NPO30”

[0086]Amount of Water Introduced to UF Membrane Module 4: 58 L / min

[0087]Solution temperature (T1) of introduced solution (permeated solution of NF membrane module 5 and solution supplied through a Chiller (not illustrated in FIG. 1) after heat exchange treatment) to UF Membrane Module 4: 20° C.

[0088]Solution temperature (T2) of returned solution (solution supplied from the circulation means 6 and solution supplied through a heater (not illustrated in FIG. 1) after heat exchange treatment) to etching bath 2: 80° C.

[0089]An etching solution in the etching bath 2 was the contaminated ...

example 2

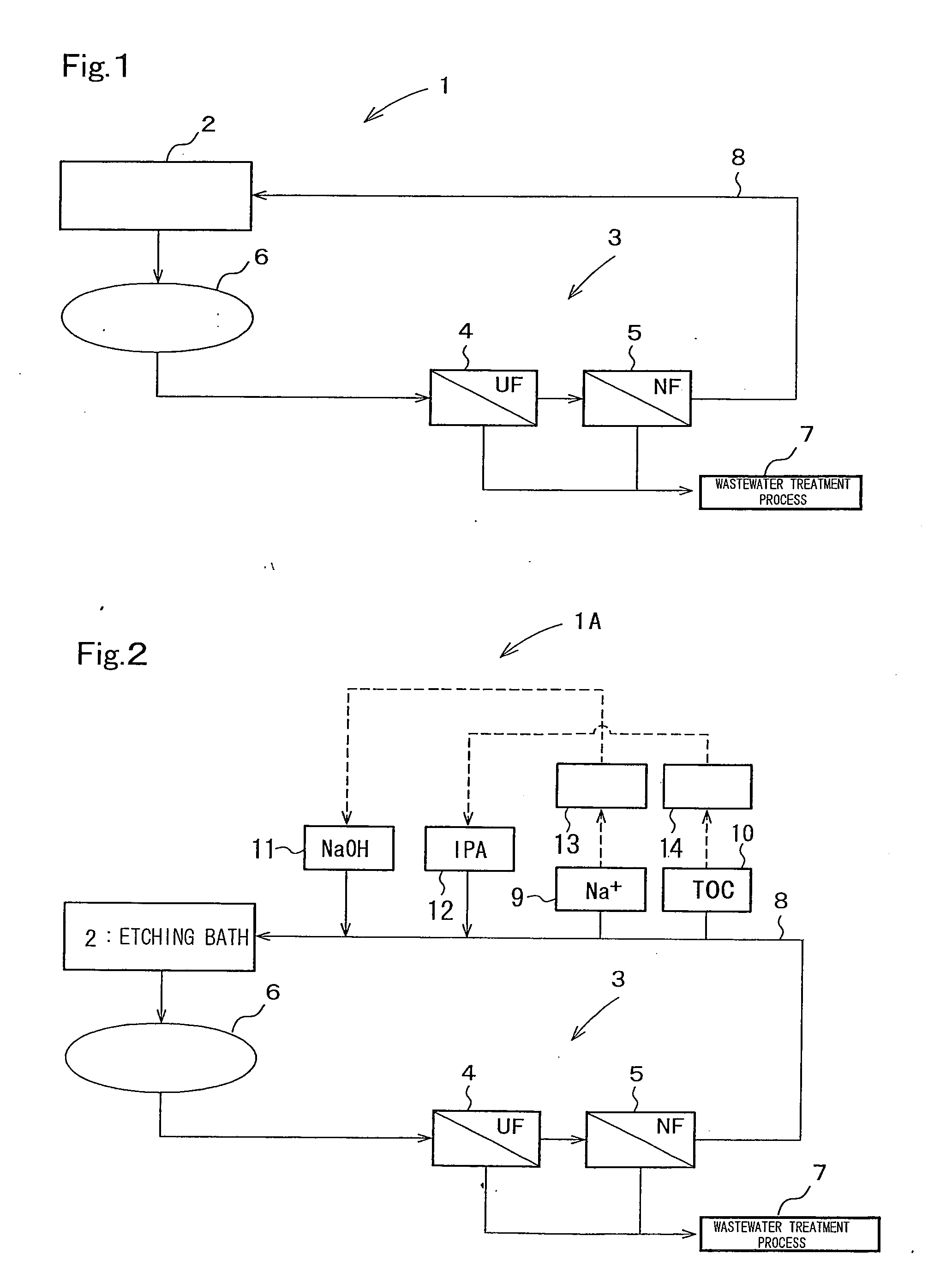

[0093]As the apparatus for treating etching solution, the apparatus as shown in FIG. 2 provided with alkaline (NaOH in the EXAMPLE) adding means and organic additive (IPA in the EXAMPLE) adding means was used. All other conditions for the etching treatment were the same as those in EXAMPLE 1.

[0094]As alkali concentration measuring means 9, a pH meter was used. A NaOH solution (24%) was added with a chemical feeding pump so that the Na+ concentration after addition would be 31,400 mg / L.

[0095]As IPA concentration measuring means 10, a TOC meter was used. An IPA solution (20%) was added to the return pipe 8 with a chemical feeding pump so that the IPA concentration after addition would be 11,700 mg / L.

[0096]The composition of the etching solution (after 12 hours elapsed since the beginning of the operation) in the return pipe 8 downstream of the point where NaOH and IPA were added is shown in Table 2.

TABLE 2EXAMPLE 1Raw Water(Removal Rate %)EXAMPLE 2SiO2 (mg / L)226009500(58%)6500Na+ (mg / ...

example 4

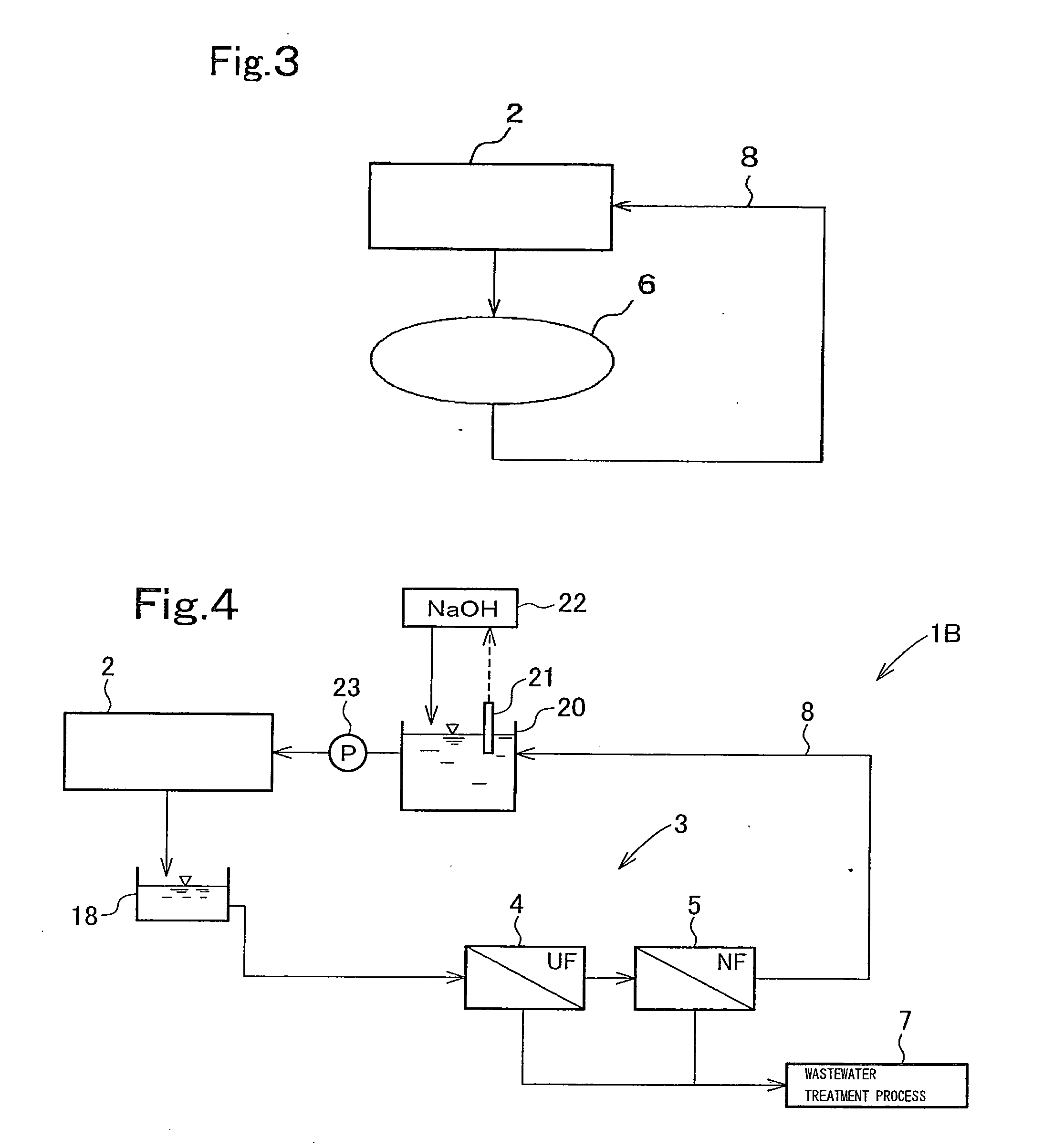

[0109]The apparatus shown in FIG. 4 was used for treating etching solution. The volume of the etching bath 2 was the same as that of COMPARATIVE EXAMPLE 2, and specifications and operation conditions of the UF membrane module 4 and NF membrane module 5 are stated below.

[0110]EXAMPLE 4 shows a result of a once-through treatment where the concentrated solution supplied from the membrane separation means 3 was not returned to the intermediary bath 18.

[0111]UF Membrane Module 4: Nitto Denko Corp., “NTU-3306-K6R”

[0112]NF Membrane Module 5: 2 8-Inch NF Membrane of Molecular Weight Cut Off 300 installed in a Series

[0113]Amount of water introduced to UF Membrane Module 4: 10 L / min

[0114]Water introduced to UF membrane module 4 was heat-exchanged with the permeated solution of NF membrane module 5 and then passed through a chiller (not illustrated in FIG. 4), and had a temperature of 50° C.

[0115]The returning water to the etching bath 2 was heat-exchanged with the solution from the intermedia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com