Oil Separator

a technology of oil separator and separator plate, which is applied in the direction of lubricant mounting/connection, vortex flow apparatus, lighting and heating apparatus, etc., can solve the problem of limited oil separation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]Hereinafter, embodiments of the present invention will be explained referring to figures.

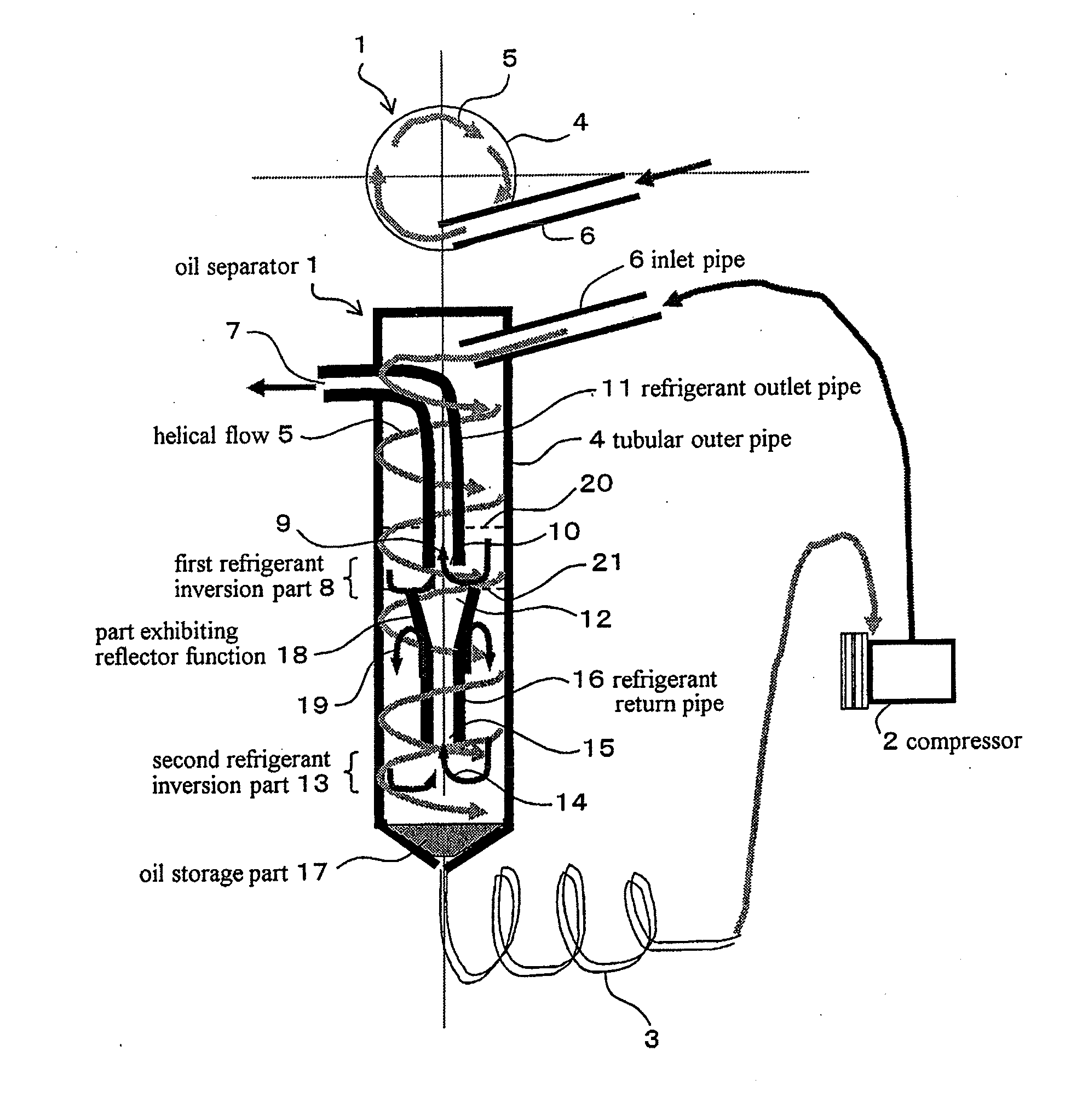

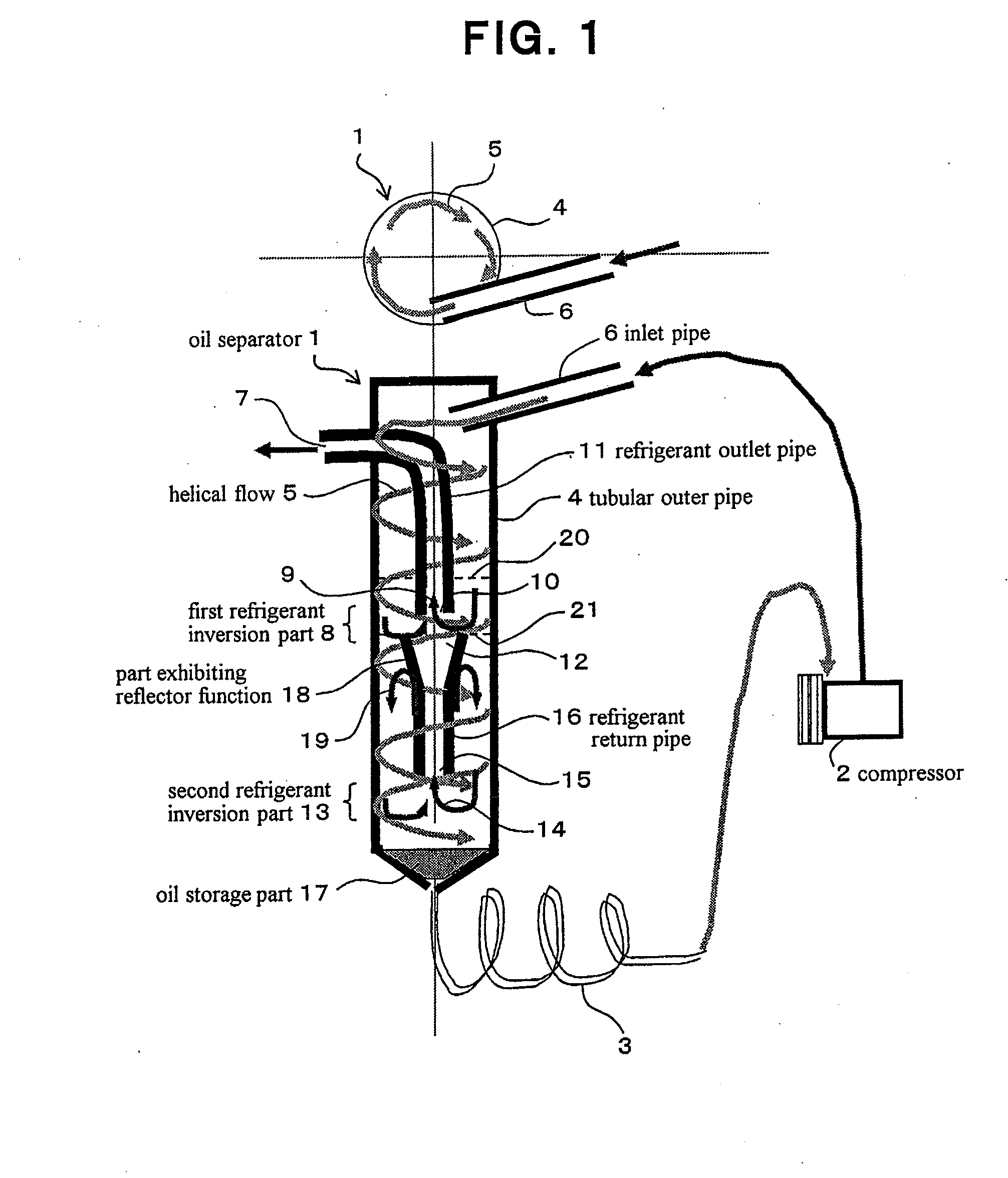

[0040]FIG. 1 shows schematic structure and operation of an oil separator according to an embodiment of the present invention. In the figure, symbol 1 indicates an oil separator, the oil separator 1 separates discharged refrigerant from a compressor 2 (high-temperature and high-pressure gas refrigerant), which contains refrigeration machine oil, into refrigeration machine oil and refrigerant, and returns the separated refrigerant to, for example, a condenser disposed at a downstream side in a refrigeration circuit, and returns the separated refrigeration machine oil into, for example, a crank case of compressor 2 through an oil return tube 3. Oil separator 1 has a tubular outer pipe 4 which is disposed on a outlet side of compressor 2 so as to extend in a vertical direction substantially at a constant diameter and at a configuration of a straight pipe, and an inlet pipe 6 provided at an upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com